Important

While BuildOps does not currently offer an HVAC duct design software, we’re always looking into new and exciting tools and technology that are moving the industry forward, which is why we’re discussing the subject here.

Clean duct layouts keep airflow steady and labor on schedule. HVAC duct design software helps your team size trunks and branches, balance static pressure, label fittings, and route around structure before anyone cuts sheet metal.

Duct design also ties into the wider operation contractors run—estimating, coordination, fabrication, and installation—across the HVAC industry. In this guide, we focus on duct design tools that support commercial service and project teams from precon through closeout.

- Choosing HVAC duct design software for your needs

- 7 key features to look for in HVAC duct design software

- Best for commercial contractors

- Best for residential contractors

- Best for general contractors

- Other notable HVAC duct design software providers

- 5 benefits of using HVAC duct design software

- 5 important HVAC duct design FAQs answered

Strong duct design comes from speed and clarity: fast edits, accurate takeoffs, clean coordination, and outputs your shop can fabricate without guesswork. The best HVAC duct design software gives crews confidence with code-driven sizing, clash checks, schedules, BOMs, and exports that drop into fabrication or field packets. Next, we’ll cover how to choose a platform that fits your crew and your projects.

Choosing HVAC duct design software for your needs

Commercial HVAC work moves fast—tight ceilings, code rules, and constant coordination. HVAC duct design software helps crews size trunks and branches, check friction loss, and hand buildable sheets to the shop. This section shows what to evaluate so you can pick the best HVAC duct design software for field teams and project managers.

- Ease of use – Can techs adjust sizes and fittings on a tablet during a site walk? Can foremen add redlines, photos, and voice notes that sync to the office? Does it auto-label ducts and fittings for quick tags?

- Cost to value – How many seats do you pay for, and which roles need access? Does it cut hours on takeoffs and revisions across typical projects? Are manufacturer libraries, training, and updates included in the plan?

- Compatibility and integration – Does it handle common design and modeling file formats without cleanup? Can models send material lists to estimating and your fab shop in one step? Do as-builts and field markups sync back to the job record?

- System support and security – Do you get live chat or phone support during work hours? Are drawings protected with secure storage and role-based access? Does version history let you roll back a change safely?

- Features – Does it follow industry standards for duct sizing and pressure calculations? Can it run clash checks, create balancing schedules, and place hanger points? Will it output spools, labels, and material lists ready for the shop?

These benchmarks help teams choose with confidence and keep jobs on schedule. Next, we’ll break down the feature set to prioritize first.

7 key features to look for in HVAC duct design software

Commercial HVAC operations face tight ceilings, quick changes, and crews moving between sites. HVAC duct design software should help designers, PMs, and installers work from the same plan, then hand clean outputs to the shop and the field. Since duct design touches scheduling, dispatch, estimating, and closeout, the best HVAC duct design software ties into daily operations and keeps every step aligned.

1. Coordinate schedules and dispatch

Design changes only help when crews see them on time. A platform that links drawings to field service scheduling and construction dispatch software keeps labor, materials, and updated sheets in sync. For example, during a mall retrofit, the office shifts a branch size after a load check; the evening crew receives the new sheet on the calendar event, the dispatcher assigns a lift, and the foreman hits the site with labels and hanger spacing ready to go.

2. Produce buildable outputs and compliance records

Designs should generate pressure-loss calculations, equipment schedules, and submittal-ready PDFs that follow industry standards used in North America. With analytics & reporting tied to each drawing, teams package calculations, balancing data, and change logs in one place. Say a medical office upgrade requires weekend work; the PM exports a compliance set with updated airflow targets and hands inspectors a single file that matches what the crew will install.

3. Turn takeoffs into clear quotes and BOMs

Accurate layouts should feed pricing fast—fittings, flex, dampers, sealant, hangers, and labor factors. When quoting software pulls quantities straight from the design, estimators send a polished proposal and a BOM the shop can trust. For instance, during a school summer project, an estimator updates a riser route; quantities refresh, the quote reflects the change, and procurement locks in fittings before lead times slip.

4. Smart sizing and balancing

Automatic sizing that follows industry standards used in North America recalculates as you add branches or shift routes. The tool flags pressure hot spots, suggests damper locations, and produces balancing tables with clear CFM targets for each diffuser. During a hospital tenant improvement, a designer moves a VAV box to meet a ceiling change; HVAC duct design software updates sizes instantly, pushes new setpoints to the sheet, and the night crew sets dampers with confidence—one reason teams call this the best HVAC duct design software for fast turnarounds.

5. Keep site details and contacts in one place

Design choices depend on room constraints, access paths, and history from prior calls. Linking drawings to CRM software gives designers and foremen quick context—mechanical room photos, ceiling heights, AHU specs, and GC contacts. For example, a high-rise tenant buildout reuses an existing trunk; the designer opens the site record, checks past static readings and photos, and routes branches to avoid fire dampers already in place.

6. Capture field feedback and labor impact

Installers spot clashes and workarounds first. When crews log hours against spools and tasks with time tracking, the office sees which fittings burn time and updates future designs. Consider a data center changeout: the night shift records extra hours on VAV tie-ins; the designer shifts to a shorter branch route on the next phase, shaving hanger counts and keeping the window.

7. 3D coordination and clash avoidance

A 3D view helps route around beams, sprinklers, cable trays, and lighting while keeping elevations and clearances accurate. Color-coded clash checks highlight conflicts and generate quick reroute options, then refresh hanger counts and labels on export. On a hotel renovation with a tight plenum, the foreman spots a collision with a sprinkler main; the designer uses clash tools to drop the trunk, slide a branch, and send updated spools before the lift arrives.

HVAC Safety Checklist for Field Services

Keep duct design safe on every job

Best for commercial contractors: BuildOps

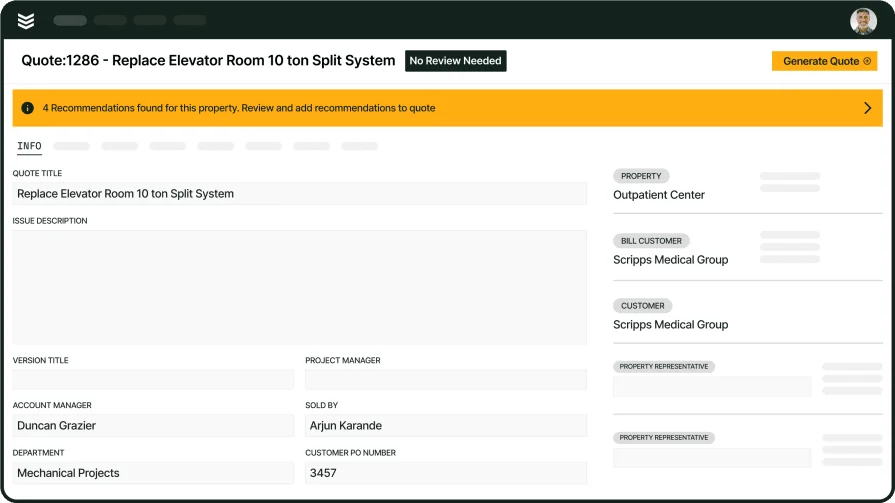

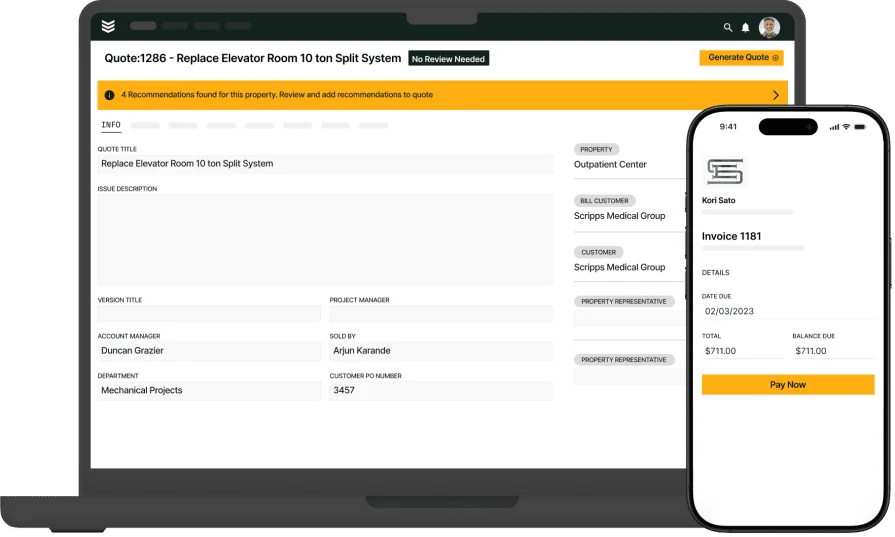

BuildOps supports commercial HVAC teams that live in the field. It runs scheduling, dispatch, work orders, photos, quotes, invoices, payments, and reporting in one place. If your designers already work in HVAC duct design software, BuildOps carries those plans into daily execution with linked tasks, job packets, and checklists. That pairing helps crews deliver exactly what was drawn and keeps shop, office, and site aligned.

How pricing works: BuildOps uses a customized model based on company size, user count, and selected modules. You pay for the capabilities that impact your operation. Onboarding and support keep your team productive quickly.

Features for field service teams:

- Real-time scheduling and dispatch

- Mobile work orders with photos and markups

- Service agreements and planned maintenance

- Job costing with time tracking

- Quoting, invoicing, and payments

- Reporting and dashboards

- Inventory and fleet tracking

What sets it apart for commercial: BuildOps excels at high-volume service and project work with tight coordination. Office and field see the same data, from labor hours to equipment records. When paired with the best HVAC duct design software, drawings flow into BuildOps as tasks, material lists, and documents your crews follow on-site. That connection reduces rework, speeds approvals, and keeps timelines steady.

Carry duct designs into the field

Scheduling and dispatch that turn layouts into finished work.

Best for residential contractors: h2x Software

h2x Software focuses on residential HVAC duct layouts and load calculations. The platform speeds room-by-room sizing, fitting selection, fan choices, and compliance outputs for permits. For small teams running split systems and packaged units, it quickly produces duct runs, register schedules, and material lists that align with shop fabrication. However, field service depth feels limited, so many teams still rely on another system for scheduling, dispatch, work orders, and payments.

How pricing works: Tiered plans align with user seats and feature access. Residential focus keeps entry costs accessible, with training and support options available.

Features for residential teams:

- Room-by-room loads and duct sizing

- Template floor plans with quick drag-and-drop

- Prebuilt fitting libraries and takeoff quantities

- Permit-ready reports and homeowner PDFs

- Basic collaboration between designer and installer

- Cloud storage with version history

- Export formats for coordination

What sets it apart for residential: Fast layouts and clear outputs help installers move quickly on single-family and small multifamily projects. For teams chasing the best HVAC duct design software for residential work, h2x delivers speed and clarity, and pairs well with a field service platform to complete the workflow.

Best for general contractors: Autodesk

Autodesk Build brings drawings, models, RFIs, submittals, and issues into one hub for GC-led projects. Teams track revisions, coordinate trades, and push updated sheets to the field with clear accountability. HVAC subs can view and compare sets, align duct routes with structure, and log clashes for quick resolution. Field service depth feels light though—dispatch, maintenance cycles, mobile work orders, and invoicing require a separate platform, so many contractors pair Autodesk with a dedicated service system.

How pricing works: Licenses scale by users, projects, and selected modules, with add-ons for coordination and cost tools

Features for general contractors:

- Document control and sheet versioning

- Model coordination with clash tracking

- RFI and submittal workflows

- Field issues and punch lists

- Photos, forms, and daily reports

- Cost management and change orders

- Integrations that accept common design formats

What sets it apart for general: Strong multi-trade coordination helps GCs keep architects, engineers, and subs aligned. HVAC teams using hvac duct design software can publish models and sheets to the Autodesk hub for clean collaboration. Many subs keep Autodesk for coordination while relying on a service platform to execute daily work, and continue evaluating the best hvac duct design software for design speed and accuracy.

Other notable HVAC duct design software providers

If your team is comparing hvac duct design software, these options deliver proven workflows contractors use every day. Each can pair with a field service platform when crews need scheduling, dispatch, work orders, and payments alongside design. Contractors still evaluate choices while aiming for the best hvac duct design software fit.

MagiCAD Ventilation

MagiCAD Ventilation runs inside common BIM environments and provides sizing, balancing, verification, and product libraries through MagiCAD Cloud. Engineers and coordinators use it to deliver calculation-backed layouts and clean documentation for installs. Field service coverage stays narrow, so teams usually add a separate platform for dispatch, maintenance, and billing.

How pricing works: Licenses sold per module and platform, with options for single or network seats

Features beyond duct design:

- Integrated calculation reports and balancing tables

- Manufacturer content with up-to-date specs

- Coordination views with clash checks

What sets it apart for engineering teams: Deep calculation and verification inside familiar design platforms.

SmartDraw

SmartDraw offers diagramming with HVAC plan templates that help teams sketch duct routes, place symbols, and create presentation-ready sheets quickly. It suits preliminary layouts, permit sets, and client communication when speed matters. Field service capability remains light, so companies typically connect it with a dedicated platform for scheduling, mobile work orders, and payments.

How pricing works: Subscription plans per user with cloud access and collaboration features

Features beyond duct design:

- Floor plan templates and HVAC symbol libraries

- Export to common CAD and image formats

- Shared folders and commenting for reviews

What sets it apart for quick layouts: Fast, approachable diagramming that produces clean plans without heavy BIM training.

Plandroid

Plandroid focuses on air-conditioning and duct design with drag-and-drop rooms and components on a floor plan. It calculates airflow, sizes branches, and compiles a parts list and quote from the same model—handy for residential and light commercial work. Field service features remain limited, so contractors often add a service platform for dispatch, maintenance cycles, and invoicing.

How pricing works: Per-seat licenses with optional maintenance and support packages

Features beyond duct design:

- Load estimation tied to equipment choices

- Parts list and costing from the layout

- Branded reports and plan exports for installers

What sets it apart for contractor teams: Simple, contractor-friendly design that turns a floor plan into a priced package quickly.

5 benefits of using HVAC duct design software

Choosing HVAC duct design software aligns designers, PMs, and installers around one plan that actually works in the ceiling. When layouts connect to scheduling, procurement, and job tracking, the best HVAC duct design software lifts field performance from first hanger to final TAB report.

1. Faster field installation

Labelled spools, hanger coordinates, and cut lists arrive with the drawing, so crews move straight to layout. Techs spend less time measuring in the plenum and extra time placing hangers, setting transitions, and sealing joints. Lift hours tighten, and supervisors keep shifts on pace without guesswork.

2. Fewer change orders

Clash checks and elevation rules catch conflicts with beams, sprinklers, and cable trays before mobilization. When revisions publish to tablets with timestamps, foremen carry the latest set and adjust routes on the fly. That clarity keeps GC coordination smooth and prevents surprise tickets that drain margin.

3. Accurate takeoffs and procurement

Quantities flow from the model into BOMs, shop lists, and vendor requests. Purchasing secures fittings and dampers early, matching lead times to the schedule. Prefab can cut and label sections ahead of installation, which shortens staging time and keeps carts rolling.

4. Better balancing and commissioning

Sizing and pressure calculations generate diffuser targets, damper positions, and test sheets tied to each space. Techs set airflows with numbers that match the plan, TAB signoff moves quickly, and warranty callbacks drop thanks to steady comfort and noise control.

5. One source of truth for office and field

Drawings, redlines, photos, and revision history live together, linked to crew schedules and job costs. PMs see progress against plan, report quickly, and reuse proven details on the next project. Field feedback loops into templates, so each phase delivers cleaner than the last.

5 important HVAC duct design software FAQs answered

With features, providers, and benefits covered above, the next step is clearing up common questions. The FAQs below explain how HVAC duct design software plugs into field work, compliance, and handoffs so you can zero in on the best HVAC duct design software for your crew.

1. What is HVAC duct design software?

HVAC duct design software is a digital tool that helps contractors plan trunks and branches, size duct, check pressure loss, and create buildable sheets for fabrication and install. It connects designers, PMs, and techs so everyone works from the same drawing, with labels, hanger points, and material lists ready for the job.

2. How does HVAC duct design software work?

The workflow starts with load inputs and a floor plan. As routes change, the software recalculates sizes and static, flags clashes, and updates schedules and BOMs. Exports create PDFs for the field, data for the shop, and files for coordination. When paired with a field service platform, updates sync to schedules, work orders, and closeout reports.

3. Who needs HVAC duct design software?

Commercial contractors, design-build shops, and service divisions benefit when projects carry tight timelines and limited ceiling space. Teams handling tenant improvements, retrofits, healthcare, education, and light industrial work see gains from clean takeoffs, faster install, and TAB targets that match the plan. Leaders searching for the best HVAC duct design software usually want speed, calculation accuracy, and clean handoffs to the field.

4. Are there any restrictions or compliance requirements to be aware of when using HVAC duct design software?

Yes. Designs must follow building codes and energy standards used in your region, plus manufacturer instructions for fittings, duct classes, and sealing. Jobs often require documentation for permits and inspections. On the data side, contractors should use secure storage, role-based access, and clear version history to protect drawings and records.

5. What are some best practices to follow when implementing an HVAC duct design software?

A short rollout plan keeps adoption smooth and ties design work to field execution.

- Pick a pilot project with predictable scope

- Define naming rules for sheets, spools, and revisions

- Load standard fittings, materials, and notes the shop already uses

- Connect exports to estimating, procurement, and fabrication early

- Train foremen on reading labels, hanger points, and schedules on mobile

- Capture field photos and redlines, then sync them back to the model

- Track labor by spool or task to see design impact on install time

- Publish updates on a set cadence so crews always carry the latest sheets

- Archive versions with sign-off so inspectors see a clean trail

- Hold a post-job review and update templates with lessons learned

Solid duct design drives safe, efficient installs and steadies margins. When drawings flow into scheduling, dispatch, procurement, and reporting, crews arrive with clear instructions and finish phases with fewer surprises. That single source of truth helps office and field move in lockstep.

Your next step is simple: align design speed, calculation accuracy, and field execution. Contractors who evaluate the best HVAC duct design software look for tools that deliver buildable outputs and connect cleanly to field service. Choose a stack that turns layouts into finished work without extra hassle.

Unify HVAC field service operations

Connect layouts to schedules, work orders, and reporting.