Managing inventory might not be the flashiest part of running an electrical contracting business, but it’s one of the most critical. When tools and materials go missing—or aren’t where they should be—crews lose time, jobs slow down, and profits take a hit. This guide breaks down how to bring order to the chaos.

Whether you’re running service trucks, maintaining a warehouse, or juggling both, you’ll find practical strategies here to take control of your stock and keep your jobs moving. If you’re part of the electrical industry, you already know the cost of downtime and disorganization. It’s time to fix that. Here’s what we’ll cover:

- What is electrical inventory management?

- Electrical inventory list management: how to keep track effectively

- 7 benefits of having an integrated electrical inventory management system

- 10 electrical inventory management best practices you should follow

- 3 best electrical inventory management solutions

Before we get into tools, templates, or tactics, let’s nail down the basics. What does electrical inventory management actually mean—and why does it matter so much for contractors? Let’s break it down.

What is electrical inventory management?

Electrical inventory management is the process of organizing, tracking, and replenishing materials, tools, and equipment used by electrical contractors to ensure that everything needed for a job is available when and where it’s required. It helps avoid delays, minimize loss, and maintain jobsite readiness.

At its core, this system covers how parts move through your business—from purchase, to storage, to the moment they’re pulled from a service van or warehouse shelf. Whether you’re managing supplies across multiple job sites, service trucks, or a central storage hub, good inventory practices help you avoid overordering, cut waste, and reduce the number of callbacks due to missing parts. It’s about keeping your crew moving and your projects on track—without wasting time hunting down a breaker or box of wire.

How does inventory management for electrical contractors work?

Electrical inventory management connects the dots between supply and service. It brings control to the chaos of daily job demands and shifting material needs. Here’s how it typically plays out on the ground:

- Purchase orders and receiving: Materials are ordered based on upcoming jobs, stock levels, or trends. Once received, items are logged and labeled into a tracking system or spreadsheet—ideally something smarter than pen and paper.

- Stock organization: Tools and materials are assigned storage locations—whether that’s a warehouse shelf, jobsite trailer, or van compartment. The goal: anyone on the crew should know exactly where to find what they need.

- Tracking usage: Items are checked in and out as they’re used. This helps you spot what’s getting burned through fast and flag what’s sitting untouched. Some shops use barcode scanners or mobile apps. Others run on spreadsheets and clipboard logs.

- Reordering: Low-stock alerts or regular reviews trigger reorders. The smarter your system, the faster you catch shortages before they delay jobs.

- Job costing & reporting: Materials are tied back to specific work orders or service calls. This gives visibility into how much material each job actually uses, which improves estimating accuracy and helps reduce overages.

In short: it’s a loop. Order, store, track, replenish. Repeat. When the loop breaks—so does the job flow.

Why automated inventory management is so critical for electrical contractors

Manual inventory tracking leads to blind spots. Parts go missing. Crews show up unprepared. And jobs stall while someone runs to the supply house. Automation solves that before it becomes a problem. Here’s what automated systems actually deliver:

- Real-time visibility: See exactly what’s in stock across every van, warehouse, or job site—without needing to call around or physically check shelves.

- Faster reorders: Set thresholds to alert when stock gets low. No more guessing or scrambling the morning of a job.

- Fewer mistakes: Barcode scanning, mobile apps, and synced databases reduce the risk of human error during check-ins, pull sheets, or transfers.

- Accurate job costing: Every part used gets assigned to the correct work order. This sharpens your billing and helps spot where you’re leaking cash.

- Less admin time: Your techs aren’t spending hours on paperwork. Your office team isn’t chasing down who took what. Everyone works smarter.

And when you’ve got multiple trucks on the road, dozens of parts in circulation, and projects overlapping—it’s not just helpful to have a system like this. It’s how you keep control of your operation.

Electrical inventory list management: how to keep track effectively

If you’re running multiple crews, trucks, or jobs at once, managing your inventory list is non-negotiable. It’s what keeps you from double-ordering conduit or discovering mid-job that your techs are out of breakers. A strong list helps track what’s on hand, what’s low, and what’s missing—and if it’s digital, even better. It gives your team instant visibility without calling the warehouse or flipping through a binder.

Let’s break down what that list should actually include.

What information is included in an electrical inventory list?

Here’s what you’ll want to track for each item:

- SKU (Stock Keeping Unit): A unique code used to identify each product in your system. Helps prevent mix-ups between similar items—especially with things like conduit types or breaker models.

- Product name: The actual name used on packaging or vendor invoices. Make it searchable and consistent across systems.

- Description: Short details that differentiate it from similar items. For example, “THHN copper wire, 12 AWG, red jacket.”

- Quantity on hand: How many are currently in stock across all locations.

- Reorder point: The threshold where you want the system to flag low stock and trigger a restock.

- Location: Where the item is stored—warehouse bin, jobsite trailer, service van, etc.

- Vendor: Who you buy it from and any related contract pricing.

- Unit cost: What you paid per unit. Important for job costing and estimating.

- Last restocked date: Helps track material turnover and flag slow-moving stock.

Electrical items and materials to keep track of in an electrical inventory list

Here’s a solid starter list of high-priority materials that electrical contractors commonly track—and why each one matters:

- Circuit breakers: Essential for distribution panels. Different jobs require different amperages and models.

- Conduit (EMT, PVC, flexible): Needed on nearly every job. Keeping the right size and type stocked avoids unnecessary runs.

- Wire & cable (THHN, Romex, MC cable): Vary by job and code requirement. Color coding and gauge size must be accurate.

- Electrical boxes & covers: From junction boxes to switch boxes—these are the backbone of clean installs.

- Switches & outlets: Basic components, but they come in dozens of types and ratings. Easy to run out without tracking.

- Connectors & fittings: Tiny items, big importance. From wire nuts to strain reliefs, they add up fast if not monitored.

- Light fixtures: From recess cans to industrial bays. Often job-specific but worth tracking due to lead times.

- Tools & testers: Inventory should include shared equipment like multimeters, knockout sets, or megohmmeters.

- Personal protective equipment (PPE): Gloves, eyewear, arc flash gear—critical to track for safety and compliance.

- Consumables: Tape, labels, zip ties—cheap but vital. They’re the items you burn through quickly and need restocking often.

Top 3 electrical supply inventory list templates

When it comes to keeping your inventory list tight, these templates can give you a head start. Whether you’re managing gear in a single van or juggling stock across job sites and a warehouse, these tools help make the job easier—without building a system from scratch.

- Smartsheet: This spreadsheet-based template lets you track stock levels, reorder points, item descriptions, and vendors—all in one view. It’s easy to update and great for shops already working in Excel or Google Sheets but needing more structure. It also includes visual indicators for low inventory, which helps you stay ahead of material shortages.

- Coefficient: Coefficient plugs directly into Google Sheets and turns your spreadsheet into a dynamic inventory system. You can set it up to auto-update quantities, pull in vendor data, and alert your team when stock hits reorder levels. It’s perfect if you want to stay inside the Google ecosystem but still get advanced features without code or custom builds.

- ProjectManager: This one’s made for teams juggling inventory alongside job schedules and project timelines. It blends inventory tracking with task management, so you can align material availability with deadlines. If your team handles a lot of jobsite coordination, this template keeps materials and project progress synced.

Templates are a solid start—but they only go so far. If your inventory isn’t connected to scheduling, work orders, and job costing, you’re still chasing parts and patching holes.

Get the service work toolkit

Access leading strategies, real-life examples, and pre-built templates.

7 benefits of having an integrated electrical inventory management system

Inventory doesn’t just sit in your van or warehouse—it moves. It connects to jobs, techs, invoices, and timelines. When it’s managed with disconnected spreadsheets or guesswork, things fall through the cracks. But when it’s fully integrated into your system, it works behind the scenes to keep your crew productive and your business lean. Here’s what that looks like in real life:

1. Fewer job delays

Missing parts stall jobs. Integrated inventory systems help make sure that doesn’t happen. Before a tech even gets assigned, the system can check what’s in stock and flag what’s low. That means the crew shows up with everything they need, and jobs get finished on schedule—not pushed because someone had to run out for a missing breaker or fitting.

Keeping your inventory in check means nothing if your billing doesn’t match. Use this tool to align materials used with what gets billed—reducing confusion, improving accuracy, and helping prevent job delays due to missing or untracked parts.

Expert Tip

Try this electrician invoice template to close the loop between inventory and invoicing.

2. Better material planning

Every job has its own material list. When your inventory connects with your scheduling and quoting tools, it becomes a forecasting machine. You’ll know exactly what parts are needed for upcoming jobs and whether you’ve got them. No more overbuying, underordering, or scrambling the night before. It lets you plan with confidence.

3. Accurate job costing

If you’re not tracking materials to each job, you’re guessing at your margins. Integrated inventory systems automatically tag parts to work orders. You’ll see what each job actually costs—not just labor, but every foot of wire and every connector. That insight means tighter estimates, better quotes, and fewer surprise losses on bids.

4. Real-time visibility

An integrated system gives your team live insight into stock levels—no need to call the shop or dig through paperwork. Warehouse, van, jobsite—you know what’s where, right now. It helps avoid duplicate orders and stops the “I thought we had it” problem before it hits your bottom line.

Tight inventory only works if the right gear hits the right job—and your team can see what’s available when. Get real-time visibility across trucks, jobsites, and the warehouse so nothing gets missed in the field. See how electrical dispatch software connects your materials to your dispatch board in real time.

5. Faster reordering

Manual checks lead to missed orders. But with integration, your system can automatically flag when an item drops below a set threshold. You’ll catch low stock early, keep jobs moving, and avoid overbuying that ties up cash in the wrong inventory.

6. Simplified reporting

Inventory isn’t just about stocking parts—it’s about tracking what’s moving, what’s sitting, and what’s eating your margin. With integrated reporting, you can pull insights in seconds. Which items are used most? Which are getting lost? Which vendor gives you the best deal? That data helps you run a tighter ship.

7. Smoother team communication

When inventory is built into your system, your office staff, techs, and warehouse crew all see the same thing. No more back-and-forth calls about what’s in the van. Everyone’s working from the same playbook. It reduces errors, cuts down miscommunication, and helps the whole team stay aligned on what’s needed.

10 electrical inventory management best practices you should follow

Whether you're managing inventory across trucks, jobsites, or a central warehouse, it’s easy for things to get disorganized fast. But the contractors who stay ahead don’t just “track stuff”—they put systems in place that work every day, in the field and in the office. These best practices help you stay lean, keep your crew equipped, and eliminate surprises.

1. Set minimum stock levels for high-use materials

Don’t wait until you run out of 12-gauge wire or breakers to restock. Identify which items move fastest—like wire nuts, outlets, or junction boxes—and assign a minimum stock level. Once inventory dips below that number, it triggers a reorder. This stops downtime and avoids costly same-day delivery fees or supply house runs.

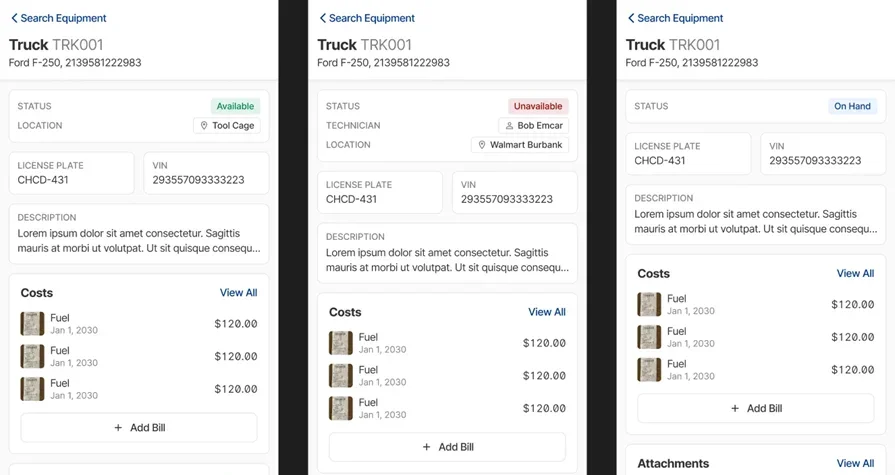

2. Assign inventory by van or crew

Each truck should be treated like a mobile warehouse. Assign materials and tools to individual vans or techs, and track usage by vehicle. That way, you’ll know what’s being used, what’s missing, and what needs replenishing—without guessing. It also helps hold techs accountable for what they carry.

Accurate bidding starts with knowing exactly what’s on hand—and what each job needs. With software that lets you assign inventory by job or crew, you can tighten your margins and avoid material overages. Explore how electrical contractor bidding software helps build better bids using real inventory data.

3. Use labels and bins for clear organization

When parts and tools are tossed into random drawers or boxes, they disappear. Use clear labels, barcode tags, and compartment bins to keep everything in its place—whether it’s in a warehouse or a service truck. Organizing by material type (lighting, conduit, fasteners, etc.) helps speed up loading and job prep.

4. Conduct regular cycle counts

Don’t wait for a big end-of-year inventory count. Instead, schedule small, regular cycle counts by item type or van. For example, count all switchgear components on the first Monday of the month, or all conduit fittings on Fridays. You’ll catch shrinkage, errors, or low stock before they become job-stoppers.

5. Link inventory to your work orders

When materials get pulled for a job, that usage should show up on the work order automatically. It’s the only way to accurately track job costs—and avoid letting unbilled parts eat into your profit. This also helps with warranty tracking if there’s an issue down the line.

6. Standardize kits for common service tasks

If your techs are handling similar types of service calls—like panel upgrades or lighting retrofits—build pre-packed kits with all the parts they need. Label them clearly and stock them on every van. This saves time during prep, ensures nothing’s forgotten, and cuts waste from partial leftover materials.

7. Centralize vendor and pricing info

Keep all supplier contacts, SKUs, and pricing in one system. That way, you’re not wasting time tracking down part numbers or calling five different reps. Having vendor info at your fingertips makes reordering faster, helps compare prices, and even gives you leverage for better deals.

8. Track tool usage along with materials

Your techs aren’t just using wire—they’re using torque wrenches, fish tapes, and knockout sets too. Track tools the same way you track parts. Knowing where each tool is, who last had it, and when it’s due back helps reduce loss, improve safety, and keep the job moving.

9. Train your team to log inventory changes

Your system’s only as good as the info going into it. Train every tech and warehouse staffer on how to check materials in and out—whether that’s using a mobile app, scanner, or sheet. Make it part of the job, not a side task. This avoids blind spots and keeps your data solid.

If your inventory’s organized, your bids should be too—and your crew needs to log what they pull to make that happen. When your team tracks material usage consistently, your estimates stay accurate and your margins stay protected. Check out these electrical bid examples to see how logging inventory changes supports tighter, more realistic bids.

10. Review usage trends every quarter

Look at which items are getting used most often, which ones aren’t moving, and what you’re overordering. Maybe you’re stocking too many specialty breakers that rarely get used, or you’re burning through MC cable faster than expected. Reviewing trends quarterly helps fine-tune your ordering and saves money long term.

3 best electrical inventory management solutions

If you’re serious about tightening up your inventory process, templates and spreadsheets will only take you so far. You need software that connects your stock levels to the rest of your operation—work orders, purchase orders, job costing, even dispatch. The good news? There are tools built specifically for that.

Before choosing one, it helps to understand what separates general inventory tools from platforms tailored to electrical contractors. If you want a deeper breakdown of the differences and must-have features, this guide on electrical inventory management software is a solid place to start.

Let’s break down the key features you should expect—and the top tools delivering them.

6 features to look for in an electrical inventory management tool

Inventory touches everything from quoting to scheduling to job completion. So when you're picking a tool, it's not just about tracking parts. It's about how well that tool plays with the rest of your operation. These are the features that actually make a difference for electrical contractors managing active inventory.

- Live inventory tracking across all locations: Whether it's on the shelf in your shop or in the back of Truck 5, you need to know exactly where everything is. Live tracking shows current stock levels by van, warehouse, or jobsite, and updates in real time as items are pulled or replenished.

- Job-linked material usage: A solid platform tracks what’s pulled for each work order automatically. That gives you tight control over material costs, helps your estimators get more accurate, and reduces the number of unbilled items slipping through the cracks.

- Mobile pull-and-log access for field crews: Your techs aren’t walking back into the warehouse to log what they just used. They need to pull parts and update inventory on the fly—right from the jobsite. Mobile access ensures usage gets logged instantly, and your inventory data stays reliable.

- Auto-restock triggers and low-stock alerts: When inventory drops below a set threshold, you get a heads-up—or even better, a PO gets generated. That keeps high-use items like wire, fittings, or fasteners from running out when you need them most.

- Purchase order and vendor syncing: Good inventory tools don’t stop at stock counts. They pull in purchase orders, pricing, and vendor info so your reordering process is faster, cleaner, and fully tracked. No more hunting down part numbers or calling five different reps.

- Usage reports and cost trend analysis: You can’t manage what you can’t measure. With built-in reports, you can see what’s being used most, where waste is happening, and how pricing is trending across vendors or material categories. That insight helps you negotiate better pricing and cut back on excess.

If you’ve got these features in place, you’re not just tracking inventory—you’re managing it like a system. Now the question is: which tools actually deliver? Let’s break down the top inventory management software picks for electrical contractors and see how they stack up in the field.

Top 3 electrical inventory management software & tools

There’s no shortage of tools claiming to help with inventory—but only a few actually deliver what electrical contractors need in the field. These three platforms stand out for different reasons depending on the type of work you do. Here’s a breakdown of what makes each one a solid pick—and where they might fall short.

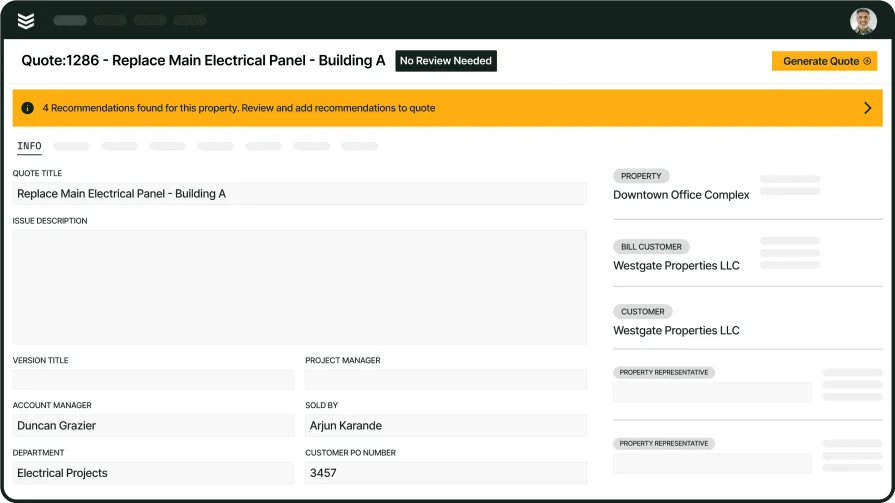

1. Best for commercial: BuildOps

BuildOps was purpose-built for commercial contractors who manage large projects, multiple crews, and moving inventory across trucks, warehouses, and job sites. Inventory connects seamlessly with scheduling, quoting, dispatch, and job costing—so the system works like an extension of your team, not a separate tool. Every material pulled gets tagged to a job, and you can track where it came from, who used it, and when it needs restocking.

What sets it apart for commercial: It’s the only platform built specifically for the complexity of commercial field service. From client asset tracking to van-level stock management, everything is tied together in real time.

See how it works in the field

Connect inventory to your full operation to manage everything from one place.

2. Best for residential: Housecall Pro

Image Source: Housecall Pro

Housecall Pro is a well-known platform in the residential space, with tools for quoting, dispatch, invoicing, and CRM. It includes some inventory features, like part tracking and job material logging, but it’s mainly geared toward smaller-scale residential shops. For simple jobs and repeat service calls, it’s easy to set up and navigate. Although, inventory tracking here isn’t as robust or deeply integrated as platforms built for larger or more complex operations. You’ll have to manage some workflows manually or through workarounds.

What sets it apart for residential: It’s user-friendly and lightweight, which makes it a great fit for small shops doing routine service and repair work.

3. Best for general contractors: Workiz

Image Source: Workiz

Workiz blends field service scheduling, job tracking, and customer communication tools into one dashboard. It offers basic inventory tools and allows you to assign parts to jobs, but it’s not as strong when it comes to managing complex stock levels or tracking across multiple locations. That said, it’s flexible for contractors who juggle multiple trades and service types. However, inventory functionality is limited. You’ll likely need to use outside systems or workarounds for real-time stock visibility or detailed material costing.

What sets it apart for general contracting: It’s adaptable for companies offering a mix of electrical, plumbing, HVAC, or handyman services and need a unified platform to coordinate everything.

Electrical inventory management plays a bigger role than most give it credit for. It’s the difference between jobs that stay on track and jobs that stall out. Whether you're tracking materials in the warehouse, restocking vans, or trying to tighten up job costing, having a solid system makes a real impact on how smooth your operations run.

The most effective setups connect inventory to everything else—like scheduling, dispatch, and quoting. That’s where things really start to click. For commercial contractors handling large teams and multi-phase jobs, an all-in-one platform like BuildOps helps tie it all together in one clean system that’s built to handle complexity without adding more work.

Give BuildOps a Try

We superpower electrical operations so you can manage projects to completion.