When maintenance jobs fall through the cracks, it’s not just a headache—it’s a hit to uptime, budgets, and customer trust. Whether you're managing dozens of assets across multiple properties or just trying to keep equipment in rotation, tracking it all with spreadsheets or whiteboards only takes you so far. Maintenance tracking software gives contractors and service teams a reliable way to manage recurring tasks, emergency work, and long-term service agreements in one place.

From HVAC and plumbing to electrical and facility maintenance, the right system keeps your team focused on the work instead of chasing down paperwork. If your company operates in the field service management industry and needs a better handle on asset and job tracking, maintenance tracking software can be a game-changer. It brings structure to chaos—helping teams know what’s due, what’s done, and what’s about to break down.

Here’s what we’ll walk through:

- How to choose the right maintenance tracking software

- 5 key features to look for in software for maintenance tracking

- 8 best maintenance tracking software platforms for all types of teams and industries

- 7 benefits of using software to track maintenance jobs

- 4 important FAQs about maintenance tracking software answered

Every company’s maintenance setup looks a little different. Some juggle planned PMs with break/fix work. Others run complex service contracts across hundreds of sites. Next, we’ll walk through what to consider before picking a tool—so it fits how your team works, not the other way around.

How to choose the right maintenance tracking software

Techs in the field need to know what needs fixing, what’s overdue, and what’s coming up. And contractors managing those teams? They need software that shows all of it in one clean view. Whether you’re handling emergency service calls, scheduled PMs, or asset repairs across multiple sites, choosing maintenance tracking software isn’t just about convenience—it’s about control. When a wrench gets turned, a filter gets changed, or a compressor fails, your system should already know what’s next.

Before picking a platform, take a hard look at how your field service team operates, what gaps you’re trying to close, and how your jobs flow from dispatch to completion. Here’s what to evaluate:

- Asset volume – How many pieces of equipment, buildings, or systems do you maintain across your contracts? Do you track small tools and large mechanical assets together—or separately? Do you need separate views for HVAC, plumbing, and electrical assets?

- Job mix – What types of work orders run through your system—preventive, reactive, warranty-related? How often do techs handle inspections vs full replacements? Do you need to group jobs by site, client, or contract?

- Tech requirements – Do certain tasks require specific certifications or licenses? How do you assign jobs based on skill or training level? Can techs see past maintenance history before starting the job?

- Compliance and documentation – Are there inspection logs or maintenance standards you need to meet? Do you need timestamped service histories for audits or customer reporting? Can the software help you document recurring issues or missed service intervals?

- Features – Does the software for maintenance tracking allow field techs to log work on-site, pull up manuals or checklists, and close out jobs with photos and notes? Can you automate reminders for upcoming PMs or flag overdue tasks? Does it offer dashboards that help your team prioritize daily work?

Contractors running field service teams live and die by the details—PM intervals, service checklists, inspection notes, and follow-up work. Maintenance tracking software should fit that level of complexity and help make sense of the chaos that builds up fast. Up next, we’ll break down the must-have features that push software for maintenance tracking beyond the basics.

5 key features to look for in software for maintenance tracking

When you're managing dozens of open work orders, preventive maintenance schedules, and unexpected breakdowns, you need software that keeps everything running without falling behind. The best maintenance tracking software doesn’t just store information—it drives the flow of work in the field. It helps contractors assign jobs, log tasks, keep up with recurring service, and track everything in real time.

These five features support the actual day-to-day movement of maintenance work—and make sure no job slips through the cracks.

1. Scheduling and dispatching

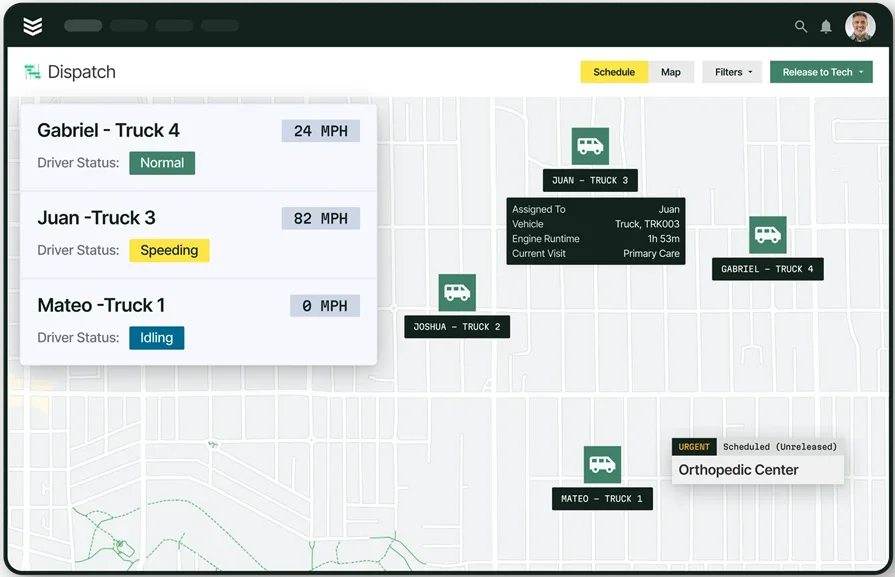

Maintenance jobs stack up fast—and without clear schedules and dispatch coordination, things fall apart. The best field service scheduling tools let you plan preventive tasks, assign reactive work orders, and keep your backlog in check. Meanwhile, dispatching software ensures the right tech shows up at the right site with the right info.

For example, a facilities contractor covering 25 commercial buildings gets a call about a water heater outage. The dispatcher pulls up available techs with plumbing certifications, assigns the job, and notifies them instantly. Meanwhile, scheduled PMs across those buildings stay on track—no double-booking, no missed service windows.

2. Mobile access for field techs

Techs need full access to job details while they’re out in the field—especially when they’re handling time-sensitive repairs or troubleshooting issues. That’s where having a strong technician mobile app becomes essential. It allows techs to pull up service history, check off tasks, upload photos, and close jobs without waiting for office input.

Take the case of a refrigeration tech who’s sent to a client site for a walk-in cooler failure. Instead of calling the office for part specs or repair history, they pull up the entire maintenance record from their phone, scan the checklist, and add a photo of the completed work before heading to the next stop.

3. Service agreement automation

Contractors with recurring service clients know the headache of manually tracking due dates, contract terms, and required PM tasks. With service agreement tools, you can automate job generation based on frequency, asset type, or client requirements—and never miss another inspection window.

Let’s say a mechanical contractor has 80 HVAC contracts with quarterly filter changes and seasonal tune-ups. Instead of building out those work orders every few months, the system auto-generates them with pre-loaded task lists, keeping techs focused and compliance tight.

4. Time tracking and job logs

Knowing how long each job takes, who handled it, and how many hours went into PM vs repairs gives contractors real insight into team efficiency. Built-in time tracking logs let techs clock in and out by job, while managers get a real view of labor spend across clients or sites.

As an example, if your team spends 4 hours every week fixing the same rooftop unit that’s been flagged for replacement, the logs tell the story. Now you can show the client hard data and recommend a capital replacement instead of pouring labor into short-term patches.

5. Maintenance reports and asset history

Maintenance tracking software only works if you can pull up the data you need—when you need it. That’s why detailed reporting tools are a must. They help track job completion, recurring issues, asset performance, and overdue work orders.

Say a property manager calls asking for proof of quarterly backflow inspections for a city audit. With two clicks, your office team pulls the full asset log, technician notes, timestamped reports, and completion photos—no digging through folders or calling your foreman.

Explore our service management suite

Equip your team with the tools they need to finish jobs fast and effectively.

Other notable features for contractors and technicians

While the core features do the heavy lifting, great maintenance tracking software also includes add-ons that make life easier for techs in the field and contractors in the office. These extra tools help teams stay aligned, tighten documentation, and keep workflows smooth from service call to invoice.

- Quoting and Estimating – Quoting software help you build accurate job estimates based on past maintenance work. It supports fast pricing for repairs or upgrades that arise during routine checks.

- Fleet Tracking – Fleet management software provides visibility into vehicle location and usage. Ideal for coordinating field techs across service areas, especially when emergency repairs come up.

- CRM Integration – A CRM lets your team access client details, equipment history, and service notes all in one place—helping improve response accuracy and communication.

- Invoicing and Billing – With invoicing software, you can generate and send invoices directly from completed work orders. Payment tools also connect to your maintenance logs, streamlining how you collect from clients after each job.

- Sales Pipeline Visibility – Pipeline tools help field service teams track upcoming opportunities, follow up on unsold repairs, and keep tabs on seasonal work that still needs to be scheduled.

Every team handles maintenance a little differently. Some prioritize tight PM schedules, others deal with high volumes of reactive work. What stays consistent is the need for tools that support how field teams actually operate—on-site, under pressure, and with no room for delays. Up next, we’ll look at seven platforms that stand out for contractors using maintenance tracking software across different jobsites.

8 best maintenance tracking software platforms for all types of teams and industries

Whether you’re managing assets across multiple sites or balancing a high volume of reactive and preventive jobs, software for maintenance tracking can help field service contractors stay ahead. These platforms represent a range of tools designed for different team sizes, job types, and industries.

1. Best for commercial field service contractors: BuildOps

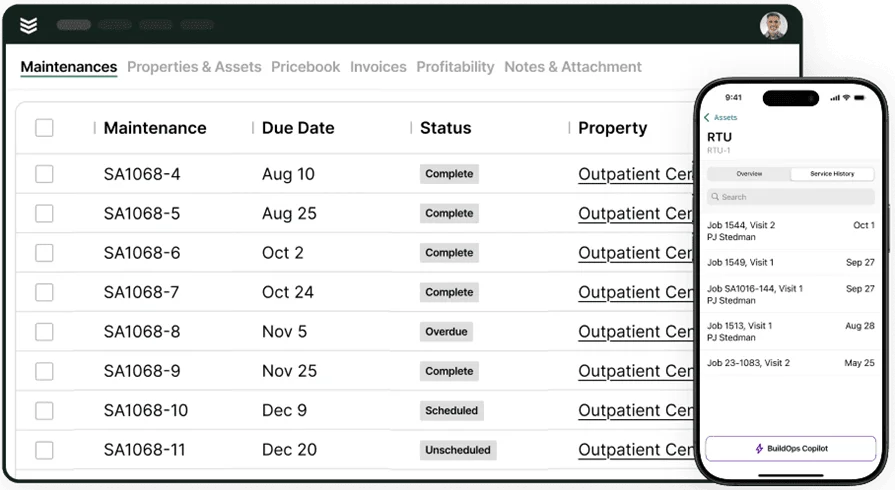

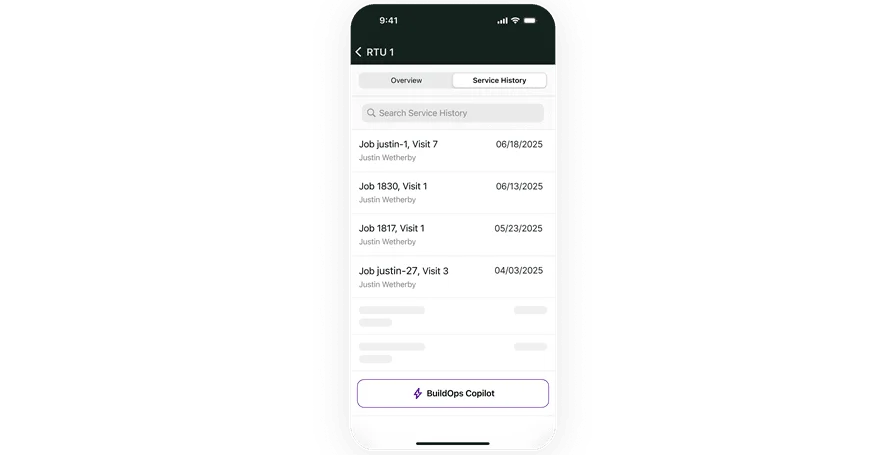

BuildOps is purpose-built for mechanical, electrical, plumbing, and facility contractors running service-heavy operations. It combines scheduling, dispatching, asset tracking, service logging, and invoicing into one streamlined platform. Maintenance jobs are tracked from initial work order to completed report—with techs logging work in real time and office teams viewing progress from a shared dashboard.

How pricing works: BuildOps follows a user-based pricing model that scales based on features and user count.

Features beyond tracking: Mobile job updates, field service scheduling, live dispatching, photo attachments, digital timecards, asset service logs, automated PMs, and invoice generation.

Why it’s best for commercial contractors: BuildOps ties every step of the maintenance workflow together—from scheduling a job to completing service documentation and billing—without bouncing between tools.

Take a closer look at BuildOps

We help contractors manage field crews, maintenance tasks, customer info, and more.

2. Best for manufacturing teams: Fiix

Image Source: Fiix

Fiix targets manufacturers looking to streamline asset maintenance on the plant floor. The platform focuses on work order automation, parts inventory management, and asset health tracking. It’s widely used by factories and industrial facilities where machines need regular checks, and downtime can be costly. Fiix may feel too equipment-focused for field service teams managing offsite or reactive maintenance work.

How pricing works: Subscription-based, with three tiers: Basic, Professional, and Enterprise.

Features beyond tracking: Asset tagging, inventory control, reporting dashboards, preventive maintenance planning, and API integrations.

Why it’s best for manufacturing: Designed to reduce equipment downtime and support large-scale maintenance tracking in a facility environment.

3. Best for mobile field techs: MaintainX

Image Source: MaintainX

MaintainX is built for mobile-first teams needing fast, flexible access to work orders. It allows techs to pull up digital checklists, asset details, and service history from the field, with a simple interface that’s easy to use. The platform is used across industries like hospitality, healthcare, and property management. It may lack deeper reporting and contract-level automation that commercial contractors depend on for multi-site service work.

How pricing works: Free plan available; paid plans based on feature access and number of users.

Features beyond tracking: Image uploads, team messaging, asset history, checklists, and limited analytics.

Why it’s best for mobile teams: Keeps teams connected in real time and simplifies job execution directly from a mobile device.

4. Best for property and facility teams: Maintenance Care

Image Source: MaintenanceCare

Maintenance Care is geared toward property managers and facility teams that handle internal service needs. It focuses on logging repair requests, assigning tasks, and documenting fixes—all in a clean dashboard. Used often in schools, healthcare buildings, and retirement homes. Its setup may fall short for contractors who need advanced scheduling, dispatching, or third-party tech coordination.

How pricing works: Offers a free plan with basic features; premium versions unlock additional tools.

Features beyond tracking: Facility-wide dashboards, work order forms, preventive maintenance scheduling, and mobile compatibility.

Why it’s best for facility teams: Helps manage internal building repairs, room-by-room service, and non-urgent maintenance tasks with better visibility.

5. Best for PM-focused teams: Limble CMMS

Image Source: Limble CMMS

Limble is built around preventive maintenance planning and asset lifecycle tracking. Contractors or in-house teams can use it to plan recurring maintenance, set equipment rules, and receive alerts when tasks are overdue. It's known for its robust feature set and flexibility. However, for fast-paced field teams that need real-time dispatching or invoicing tools, Limble may require additional integrations.

How pricing works: Tiered pricing with a per-user monthly rate. Free trial available.

Features beyond tracking: Preventive maintenance triggers, asset profiles, real-time alerts, checklists, reports, and mobile features.

Why it’s best for PM-heavy operations: Focused on reducing breakdowns and keeping long-term service timelines on track.

6. Best for schools and universities: FMX

Image Source: FMX

FMX helps schools, universities, and campus facilities track repairs, schedule preventive tasks, and manage assets across multiple buildings. It features calendar-based maintenance tracking, inventory logging, and equipment lifecycle monitoring. FMX works well in environments with centralized staff and predictable job types. Its features may feel limited for contractors working across client locations or needing more complex mobile dispatching.

How pricing works: Subscription pricing based on the number of users and facility locations.

Features beyond tracking: Calendar view of work orders, asset maintenance logs, inventory tracking, and custom reporting.

Why it’s best for educational facilities: Designed for internal maintenance teams managing repairs across campus-based environments with recurring job types.

7. Best for simple service workflows: Maintainly

Image Source: Maintainly

Maintainly focuses on ease of use for teams that want a low-friction way to track maintenance tasks. Its platform includes work order creation, task assignment, and preventive scheduling. It’s a fit for contractors handling lighter volumes of jobs with straightforward workflows. Maintainly may lack deeper asset tracking, third-party integrations, or project-level breakdowns needed by larger field service teams.

How pricing works: Offers a free plan with paid tiers based on feature depth and user limits.

Features beyond tracking: Drag-and-drop scheduler, PM templates, asset logs, mobile app, and basic reporting.

Why it’s best for small service teams: Great for contractors who need a simple, functional system for basic task tracking and updates.

8. Best for government and public sector: FacilityForce

Image Source: FacilityForce

FacilityForce is an enterprise-grade system for public sector facility maintenance. It provides full lifecycle tracking for assets, compliance-driven maintenance plans, and integration with financial systems. Governments, airports, and public buildings use it to centralize all facility upkeep. The complexity of setup and high cost may make it less ideal for private contractors focused on faster job turnover or shorter service cycles.

How pricing works: Customized pricing based on organization size and system configurations.

Features beyond tracking: Asset lifecycle planning, regulatory compliance tracking, financial system integration, and deep reporting tools.

Why it’s best for public facilities: Ideal for structured, policy-driven maintenance programs with strict documentation needs.

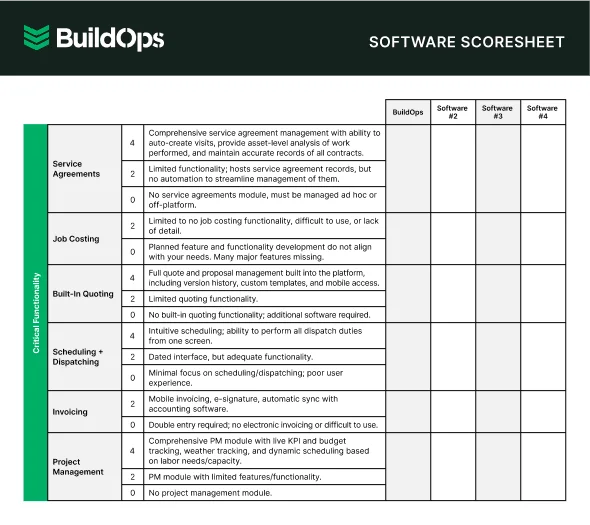

Get the software scoresheet

Compare the top tools at a glance with this easy-to-use scoresheet.

7 benefits of using software to track maintenance jobs

Maintenance work is about keeping the whole system moving. Contractors and techs need a way to monitor tasks, document work, and stay ahead of potential issues without chasing paper trails or toggling between apps. That’s where maintenance tracking software pays off. These benefits go beyond convenience—they directly impact how efficiently teams operate every day.

1. Faster job turnaround times

When techs know exactly where to go, what needs doing, and have everything they need on their device, jobs get done faster. Work orders come through in real time, and there’s no need to call back to the office. This benefit becomes even clearer when using field service scheduling strategies that keep crews organized and gaps in the calendar filled. Faster turnaround reduces overtime and helps your team knock out more jobs in a day without sacrificing quality.

2. Visibility across the whole operation

From backlog to completed work, having visibility across jobs and assets lets contractors spot trends early. Maintenance logs tell the full story—what broke, how often, and what it took to fix it. Tools like field maintenance software help make that data usable, so decisions aren’t based on guesswork. With full visibility, it’s easier to plan PMs, order parts ahead of time, and avoid scrambling during breakdowns.

3. Clearer communication with field techs

Techs working blind lose time. With software for maintenance tracking, they get job details upfront, updates instantly, and can log work as they go. That reduces back-and-forth and speeds up progress. Better communication also depends on systems that track field employees accurately—knowing who’s doing what and where, without micromanaging. Clearer communication also leads to fewer mistakes, tighter coordination, and smoother handoffs between shifts.

4. Better documentation for compliance and reporting

Digital records replace handwritten notes, reducing errors and giving teams a searchable history of past service. That kind of documentation matters when clients ask for proof or when regulations require audit trails. When every work order is tied to a timestamp and asset log, it’s easier to show you’ve done the work. Detailed reporting also helps contractors secure repeat business by showing clients exactly what’s been maintained and when.

5. Stronger accountability on time and labor

Job logs and time entries give visibility into how long each task really takes. When your team uses time tracking for field technicians, you see patterns across techs and job types—helping you plan workloads better and improve accuracy on estimates. With more accurate labor data, you can prevent burnout, forecast hiring needs, and strengthen job costing.

6. Smoother ticketing and job handoffs

Missed jobs often come down to messy handoffs. With field service ticketing systems, incoming requests are converted into work orders that are logged, tracked, and assigned—no loose notes or forgotten messages. This keeps jobs moving from intake to execution without delays. Streamlined ticketing also improves customer satisfaction since nothing falls through the cracks.

7. Reduced equipment downtime

When maintenance tasks are logged, tracked, and repeated on schedule, equipment stays online longer. You can spot recurring issues, adjust PMs, and act before failures happen. That proactive approach only works when software keeps everything on record and reminds your team when it’s time to act. Over time, this cuts emergency repair costs and helps extend asset life.

4 important FAQs about maintenance tracking software answered

Contractors rely on tight systems to manage everything from emergency repairs to long-term service contracts. When your team is in the field, the maintenance tracking software you choose plays a major role in how smoothly the day runs. It affects how techs receive job info, how office staff monitors progress, and how service history gets logged and accessed later. These FAQs break down the key points contractors care about most—before committing to a platform.

1. What is maintenance tracking software?

Maintenance tracking software helps contractors and technicians monitor and manage service work across equipment, buildings, and job sites. It’s designed to replace spreadsheets and paper trails with one digital system that logs work orders, tracks progress, and keeps asset history organized.

Teams can assign jobs, schedule preventive tasks, document repairs, and access service logs from anywhere—making sure no job gets lost and no detail gets skipped. Whether you're servicing commercial HVAC systems or maintaining building infrastructure, having all job details centralized gives field crews and office teams a shared view of what’s been done and what’s next.

2. How does maintenance tracking software work?

Software for maintenance tracking connects work orders, job history, scheduling, and asset data all in one place. It supports real-time updates and keeps the team aligned. Here’s how it typically functions:

- Work order creation: Managers create jobs based on service calls, PM schedules, or flagged issues.

- Scheduling and assignment: Tasks are assigned to field techs based on skills, availability, or route proximity.

- Mobile updates: Techs receive job info on their device, log tasks, take photos, and close out the work.

- Asset history tracking: Every action is tied to a specific asset—giving contractors a searchable record of what’s been done, when, and by whom.

The best systems also sync with invoicing, reporting, and dispatch tools—keeping operations unified across departments.

3. Is maintenance tracking software worth the cost for contractors?

Absolutely—especially for field service teams managing repeat service calls, high job volumes, or multi-site clients. Manual systems introduce delays, missed tasks, and inconsistent reporting. Maintenance tracking software solves those issues by giving crews clear direction, automating routine work, and documenting job history in real time.

Contractors also benefit from better resource allocation and reduced equipment downtime. With clearer job logs and faster access to data, office staff spends less time chasing paperwork, and techs spend more time getting work done. For teams looking to scale, the long-term savings in labor, efficiency, and client retention add up fast.

4. What are some maintenance tracking software best practices to follow?

Buying software is only half the equation. Getting full value means using it consistently and building good internal habits. Here are ten best practices top contractors follow to get results:

- Assign every asset a digital profile with service history, warranty info, and maintenance requirements

- Use recurring work orders to automate PMs by task type, frequency, or client contract

- Create task checklists to ensure techs complete every step during service

- Require photo documentation before closing out jobs

- Enable mobile logging so techs can upload updates on the spot

- Tag jobs by service type—repairs, PMs, inspections—for better reporting later

- Review overdue work orders weekly to catch delays early

- Build reports by asset type or location to spot recurring issues

- Limit user permissions based on role to protect sensitive data

- Revisit job templates quarterly to update scopes and remove unnecessary steps

Whether you’re tracking 20 assets or 2,000, managing preventive work, or responding to unexpected repairs, the way your team logs and follows through on maintenance matters. Software built specifically for field service teams can take the pressure off both your techs and your back office—by keeping schedules tight, records clear, and tasks visible from the first call to the final invoice.

For commercial contractors, the biggest gains come from using a single platform that handles it all. Maintenance tracking software works best when it’s connected to the rest of your operations—dispatch, scheduling, reporting, time tracking, and invoicing—so the full picture lives in one place. That’s where all-in-one platforms like BuildOps make a real difference, giving you the tools to manage the entire job lifecycle without bouncing between apps or second-guessing your data.

Curious to see how BuildOps works?

We connect maintenance tracking with everything else your crews need in the field.