Tracking every valve, pipe, and coupling can feel like a full-time job—especially when projects are stacking up. For teams in the plumbing industry, inventory headaches often lead to job delays, lost revenue, and frustrated crews. When materials go missing or stock levels are off, your whole operation slows down. That’s why plumbing inventory software matters—it gives your team real visibility into what’s in stock, what’s used, and what needs to be reordered.

Here’s what we’ll cover in this guide:

- Choosing the best plumbing inventory software for your team

- 6 key features of inventory management software for plumbing contractors

- 8 best plumbing inventory software picks for contractors

- 7 benefits of using plumbing inventory management software

- 4 common plumbing inventory software FAQs answered

Before we dive into tools and features, let’s step back and look at what really matters when picking a system. The right setup cuts the unnecessary stress of tracking inventory and keeps your materials moving without the guesswork. Let’s break down the key considerations before locking into a platform.

Choosing the best plumbing inventory software for your team

You don’t need another system collecting dust. You need one that fits how your crew works—whether that’s handling emergency leaks or lining up installs across five job sites. Before you choose a platform, line up what’s actually happening in your workflow and where things fall apart. Here’s what to look at:

- Job volume and type - Are you running high-volume service calls, large commercial installs, or a mix of both? The size and pace of your jobs shape the kind of inventory tools you’ll need—some platforms handle fast-moving parts better, others are built for project staging and long timelines.

- People involved - Who’s actually managing parts? Is it the warehouse manager, the office staff, or your techs in the field? A solid system should support everyone who touches inventory—from the shop floor to the back of the truck.

- Current process - If you're still working off spreadsheets or whiteboards, odds are you're losing track of materials. Missed restocks, duplicate orders, and mystery shortages happen when there's no real system. Pin down your current weak spots before adding a new tool on top.

- Integrations with other tools - Do you need inventory to sync with dispatch, quoting, or invoicing? If your current tools are already dialed in, make sure the inventory software can connect without causing friction.

- Features - Can it assign parts to specific jobs? Track stock across trucks, warehouses, and vendors? Is there mobile access so your field crew can check availability on the fly? Look for real-time usage tracking, restock alerts, barcode scanning, and reporting that actually tells you what’s getting used—and what’s just collecting dust.

Once you’ve mapped this out, you’ll have a better handle on what kind of system actually solves problems—not adds to them. Next, we’ll dig into the features that make the biggest difference on the job.

6 key features of inventory management software for plumbing contractors

Inventory problems don’t always show up on reports—they show up on jobsites. A missing fitting, an overstocked part nobody uses, or a tech driving across town to grab something that was already in the next truck over. These situations slow jobs down, drive up costs, and frustrate your team. The fix? Software that puts you in control of what’s moving, what’s sitting, and what’s needed next.

Let’s say your team is mid-project at a medical facility. One crew is roughing in patient bathrooms while another is working on the mechanical room. They’re both pulling from the same inventory pool. A tech checks availability on his phone, sees there’s a shortfall on supply stops, and shifts extras from another truck—without calling the office or delaying the schedule.

Here are six features that make that kind of visibility possible.

1. Invoicing & payment solutions

When parts move, dollars follow. Invoicing and payments tools let you track materials the second they’re pulled, tie them to job tickets, and bill accurately—without chasing down field notes or guesstimating what was used. Say, for example, after replacing zone valves in a multi-unit building, your tech logs each part through the mobile app. Everything is tagged to the job, deducted from inventory, and sent to billing—no gaps, no surprises. Your admin team can see the usage and send the invoice the same day.

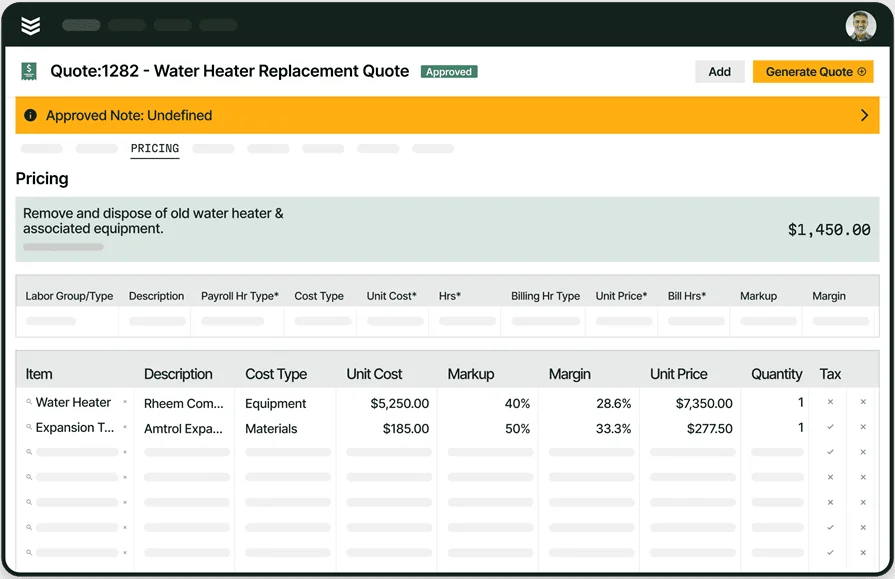

2. Quoting & estimating tools

Field quoting & estimating tools help estimators price jobs based on live material data. It connects directly to your inventory system, so quotes match real-time stock and current vendor pricing. For instance, during a large tenant fit-out, your estimator pulls prices for cleanouts, hangers, and pressure reducers from the same system that tracks your warehouse. The quote lines up with what’s actually on the shelf, and the crew rolls out knowing everything’s covered.

3. Technician mobile app

The field is no place for guesswork. With the technician mobile app, your crew can check availability, log material usage, and view inventory from wherever they are—without needing to call the office. Imagine, while working on a grease interceptor install, a tech realizes the gasket he needs isn’t in his bin. He opens the app, sees it's available in a service van across the lot, and coordinates the handoff—job stays hot, no time wasted.

4. Fleet management

Parts live in more than one place. Fleet tracking software shows what’s in each truck, how fast it’s moving, and where it’s going next. That means less over-ordering, smarter transfers, and more jobs finished on the first trip. For example, your team is repiping a school, and one tech’s running low on angle stops. Instead of running to the supply house, the office reassigns inventory from another van on-site. It’s scanned, tracked, and accounted for—without disrupting the job.

5. Scheduling & dispatching

Scheduling and dispatch software go hand-in-hand when it comes to inventory control. When work orders are tied to pre-assigned materials, and techs are dispatched with exactly what they need, you eliminate the scramble. Parts get where they’re needed—on time, every time. Take a hotel remodel where multiple bathrooms are being demoed and rebuilt. The office schedules the work, kits out the materials—everything from supply lines to escutcheons—and dispatches techs directly from the warehouse. Because the job, the people, and the parts are all synced up, your crew hits the ground running, and inventory stays tight.

6. Reporting tools

Field reporting tools show you what’s moving and what’s not—so you buy smarter, stock leaner, and stay ready for the next rush. Trends, usage patterns, and reorder points are all visible in one place. After reviewing Q2 data, your ops manager sees mixing valves and riser clamps surged during summer callouts. That insight helps forecast restock before the next wave hits—keeping crews equipped and avoiding delays that cut into job flow.

Other valuable features that support plumbing inventory management

While these features don’t directly manage inventory, they play a crucial role in keeping your team synced and your materials flowing. When they’re connected to your inventory software, they help reduce manual work, improve accuracy, and give the office and field a shared view of what’s going on.

- Time tracking: Time tracking gives visibility into how labor hours align with material usage. This helps with job costing and identifying waste tied to part consumption. For instance, after reviewing labor and inventory data from a series of hot water recirculation installs, your team sees they’re consistently short on pump flanges—allowing them to prep better for future work.

- CRM: A CRM software lets you track customer history, past inventory usage, and recurring service patterns. During a call for a medical office, your dispatcher checks the CRM, sees previous repairs involved pressure-reducing valves, and adds them to the job prep—saving a second trip later.

- Service agreements: Service agreements let you preload contract-specific parts and forecast inventory based on recurring jobs. Say you maintain backflow assemblies at multiple restaurants quarterly. The system pulls past usage data and preps the right kits before the next cycle starts.

Deep Dive

As highlighted in our guide to plumbing inventory management, organization starts with knowing what moves fast, where it lives, and how it’s being used across your fleet and warehouse. Whether you’re handling residential service calls or large-scale commercial jobs, the goal is the same—keep your techs stocked and jobs flowing.

8 best plumbing inventory software picks for contractors

Not every software platform fits how plumbing contractors work. Some focus on simplicity, others are built to scale. What matters is how well the tool matches the day-to-day challenges your crew deals with—from tracking fittings across vans to syncing usage with billing. Here’s a breakdown of eight top plumbing inventory software solutions, and where each one stands out.

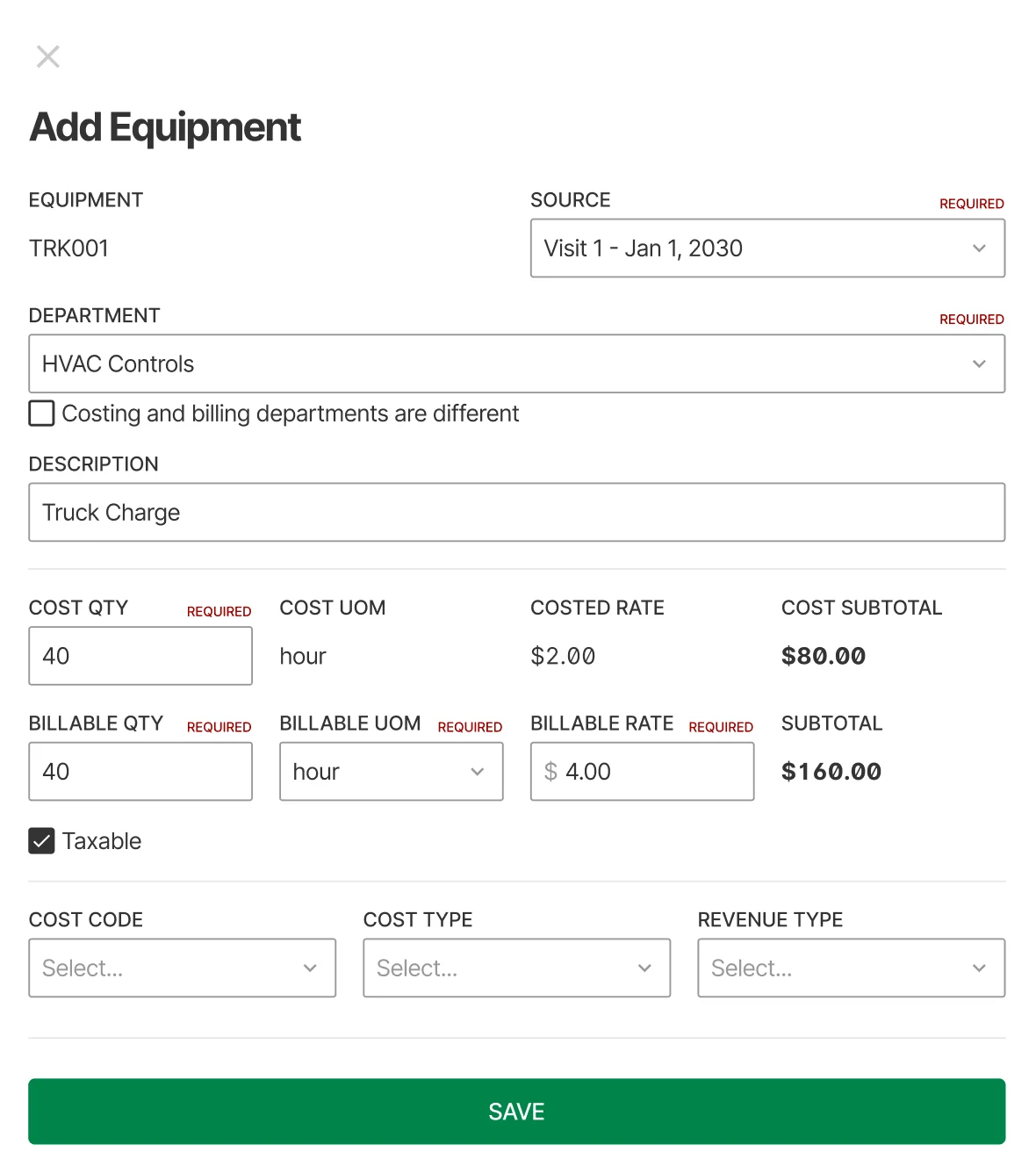

1. Best for commercial: BuildOps

BuildOps is designed for commercial plumbing contractors managing inventory across large-scale projects and mobile crews. It gives real-time visibility into stock levels, tracks material usage by job, and ties everything into one platform—from quoting and dispatching to invoicing and reporting. Built for speed in the field, it’s mobile-ready and easy to use on job sites.

How pricing works: BuildOps offers custom pricing based on company size and features needed.

Features beyond inventory management: Includes technician time tracking, advanced reporting, CRM, estimating, mobile app access, and robust service agreement management

What sets it apart for commercial: Built for high-volume operations. Whether you’ve got five vans or fifty, it handles complex workflows without lag or confusion.

BuildOps plumbing inventory software

See how BuildOps equipment and asset tracking powers commercial plumbers.

2. Best for residential: Housecall Pro

Image Source: Housecall Pro

Housecall Pro is built for speed and simplicity—great if you’re running a residential plumbing outfit and don’t want to get buried in complex tools. It handles scheduling, customer updates, and payment processing with ease, making it ideal for smaller crews. But if you’re managing multiple vans, lots of part movement, or warehouse inventory, it may not have the depth you need.

How pricing works: Starts around $59/month, with more advanced features available in higher-tier plans.

Features beyond inventory management: Job scheduling, online booking, payment collection, automated customer communication.

What sets it apart for residential: Quick to launch and easy to use. Great for solo techs or tight-knit teams that need to get in, get out, and stay organized.

3. Best for general contractors: Workiz

Image Source: Workiz

Workiz gives you the basics across dispatch, estimates, invoicing, and some inventory tracking. It’s a flexible system built for service businesses that handle multiple trades—including plumbing—but it’s not tailored for plumbing-specific inventory like fittings, valves, and kits. If you’re mostly plumbing-focused, some features may feel generic.

How pricing works: Plans start at roughly $65/month per user. Costs go up with added integrations and automation tools.

Features beyond inventory management: Call tracking, customer portal, digital forms, lead pipeline tools.

What sets it apart for general contractors: Works well for teams juggling plumbing, electrical, and HVAC jobs under one roof.

4. Best for small teams: Xero

Image Source: Xero

Xero isn’t a full-blown inventory solution—but for small shops that want basic part tracking baked into their accounting, it gets the job done. You can assign materials to invoices, track usage, and keep tabs on costs, all while managing your books. That said, it doesn’t support things like multi-van inventory, jobsite restocking, or warehouse tracking.

How pricing works: Entry-level pricing starts around $2.90/month; inventory tools are included in all paid plans.

Features beyond inventory management: Accounting, bank reconciliation, invoicing, payment tracking.

What sets it apart for small teams: Simple and budget-friendly. A good match for tight crews who want accounting and basic inventory tools in one place.

5. Best for businesses looking for free tools: Zoho Inventory

Image Source: Zoho

Zoho Inventory comes packed with features for a free platform—like barcode scanning, order fulfillment, and multi-warehouse tracking. It’s a solid entry point for small plumbing teams moving off spreadsheets. Just know it’s not plumbing-specific, so you might have to adjust how you organize fittings, pipe types, and job kits.

How pricing works: Free for teams handling under 50 orders/month; paid plans start at $59/month.

Features beyond inventory management: Order tracking, multi-channel sales, shipping integration, automation tools.

What sets it apart for businesses looking for free tools: Strong capabilities at zero cost—ideal for teams starting to take inventory seriously without spending upfront.

6. Best for visual inventory tracking: Sortly

Image Source: Sortly

Sortly gives you a clean, visual way to manage parts using photos, tags, and folders. If your team prefers seeing inventory rather than scrolling through long lists, this setup works well—especially for organizing job kits or tracking assets in trucks. But for plumbing contractors handling complex restocks or syncing usage with job costing, it might feel a little too basic.

How pricing works: Free option available; paid plans start at $49/month.

Features beyond inventory management: Mobile access, custom folders, QR and barcode scanning, asset tagging.

What sets it apart for visual inventory tracking: Designed for teams that want an easy, image-first way to stay on top of tools and parts—without a steep learning curve.

7. Best for warehouse-centric operations: inFlow Inventory

Image Source: InFlow

inFlow Inventory is built for businesses that rely heavily on warehouse stock. It handles vendor management, barcode scanning, purchase orders, and real-time tracking across locations. If your plumbing company runs a centralized warehouse with high-volume stock movement, it’s a solid choice. Just know that it’s not made with plumbing fieldwork in mind, so mobile field access may be limited.

How pricing works: Plans start at $89/month with full inventory features.

Features beyond inventory management: Purchase orders, vendor catalog management, sales tracking, reporting dashboards.

What sets it apart for warehouse-centric operations: Excellent depth for managing bulk parts and warehouse flow—great for teams with a steady inbound/outbound materials process.

8. Best for integrated retail and inventory: Square POS

Image Source: Square

Square POS isn’t just a point-of-sale system—it comes with inventory tools that work well for plumbing shops selling parts or fixtures at a counter. It adjusts stock in real time with every transaction, supports barcodes, and tracks item sales. But it’s not built for field dispatch or managing inventory across service vans and job sites.

How pricing works: Free to start, with optional add-ons and transaction fees.

Features beyond inventory management: POS tools, customer directory, permissions management, retail sales reporting.

What sets it apart for integrated retail and inventory: Solid option for plumbing shops running retail alongside service—helping sync what’s sold with what stays stocked.

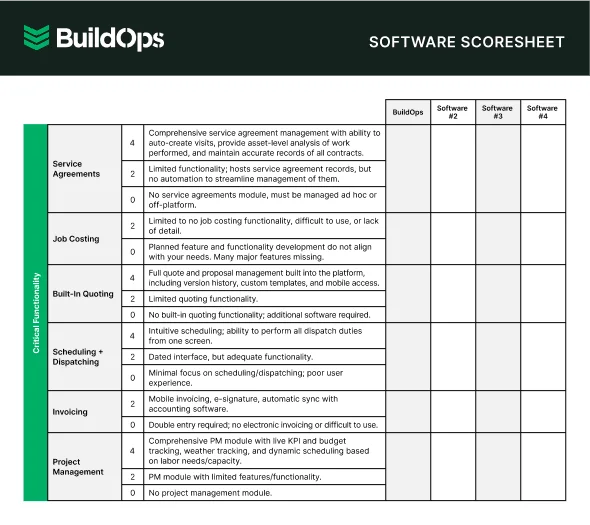

Contractor Software Scoresheet

Having trouble deciding? Use our software scoresheet to compare your top options.

7 benefits of using plumbing inventory management software

Inventory systems don’t just track materials—they drive better planning, cleaner billing, and tighter coordination between the field and office. For plumbing contractors, these benefits go far beyond the warehouse. They affect every part of the job cycle, from quote to final invoice.

1. Accurate invoicing from the field to the final bill

When inventory is tracked as it’s used, billing becomes faster and more reliable. Each part pulled ties directly to the work performed, reducing back-and-forth between teams and cutting billing errors. Our comprehensive guide to plumbing invoicing outlines how real-time material tracking supports more transparent, professional billing workflows that keep cash flow moving.

2. Fewer delays from missing parts

Stockouts throw off entire days of work. Inventory tools help detect low quantities before they become emergencies. Combined with structured billing systems, this keeps your team working instead of scrambling. Plumbing invoice templates helps standardize how materials are documented, so shortages don’t go unnoticed or unbilled.

3. Better visibility into customer service needs

Tracking material history across customers gives your team context before the truck rolls out. This makes it easier to load the right kits and avoid unnecessary callbacks. With a tool like a CRM for plumbers, you can link service history to parts usage and plan every visit with inventory already in mind.

4. Smarter job planning

Knowing what parts are available—and what’s assigned to each job—keeps schedules on track and techs prepped. Inventory systems that work with scheduling tools allow you to align labor and materials efficiently. As covered in our plumbing field service software overview, syncing these systems reduces wasted time and improves completion rates across all job types.

5. Tighter purchasing decisions

Inventory usage reports show what’s moving fast and what’s sitting idle. This helps plumbing companies spend smarter, avoid overstocking, and get ahead of seasonal demand. The insights shared in our plumbing company growth data reflect how strategic inventory planning supports long-term profitability and scalability.

6. Easier job costing and margin tracking

When materials are logged by job, you gain clearer insight into what each project actually costs. This supports better estimating on future work and allows managers to adjust labor and material budgets as needed. It also gives finance teams cleaner reports tied directly to usage—making inventory a key part of margin control.

7. Stronger coordination between teams

With connected systems, your warehouse, office staff, and field crews all work off the same data. There’s no second-guessing stock levels or part availability. Inventory that updates in real time supports smoother scheduling, cleaner dispatching, and fewer mid-job surprises—all without extra admin load.

4 common plumbing inventory software FAQs answered

Choosing the right inventory software for your plumbing team raises a few common questions—especially when you’re managing multiple trucks, jobsites, and supply points. These answers cover what most contractors want to know before making the switch.

1. What is plumbing inventory software?

Plumbing inventory software tracks parts, tools, and fittings across your warehouse, vehicles, and job sites. It helps contractors monitor stock levels, assign materials to specific jobs, and avoid costly shortages or duplicate orders. The software also connects with other parts of the workflow.

These include invoicing, scheduling, and dispatching. It also gives your entire team a clear view of what’s available—and what’s already spoken for.

2. How does inventory management software for plumbing contractors work?

Plumbing inventory software tracks parts across your shop, trucks, and jobs. It shows you what’s on hand, what’s been assigned to work orders, and what needs restocking. Here’s what it typically handles:

- Logs inventory across multiple storage locations

- Tracks part usage in real time through mobile access

- Ties materials to specific jobs and service calls

- Updates stock levels automatically

- Triggers restock alerts when items run low

- Connects with quoting, invoicing, and dispatch systems

- Supports barcode scanning and digital check-outs

- Stores usage history for audits and job costing

- Syncs with scheduling and reporting tools

With everything connected, your techs and office stay aligned—and jobs don’t get held up over missing parts.

3. Is inventory management software worth it for plumbing contractors?

Yes—especially for teams managing high part volume or multiple crews. The costs of manual tracking add up quickly: lost stock, duplicated orders, billing errors, and job delays. Inventory software reduces those hits by giving you accurate numbers, automated restocks, and connected data across your entire operation.

It also cuts down time spent hunting for parts or reconciling inventory by hand—freeing up your techs and admins to focus on actual work, not paperwork.

Did you know

Our customer Classic Electric certainly thought the price of BuildOps was worth it when they saw 300% growth. See how BuildOps brought everything together for them, and learn how you could see the same results in your business.

4. What are some best practices for rolling out a plumbing inventory system?

Getting started with a new system takes some prep. Here are proven tips to help your rollout go smoother:

- Set minimum stock levels for frequently used items like fittings, valves, and PEX

- Organize inventory by truck and location so nothing gets lost in transit

- Use labels, bins, and scanning tools to improve accuracy

- Schedule regular counts to keep numbers tight year-round

- Tie inventory usage directly to job tickets for clear billing

- Standardize material kits for common services like water heater swaps

- Centralize vendor and pricing data to streamline reordering

- Train techs and warehouse leads on mobile logging and scanning

- Track tool usage along with materials to reduce loss

- Review part usage monthly to adjust ordering and catch trends

These steps help you avoid clutter, reduce waste, and make inventory a core strength in your day-to-day work.

For plumbing contractors, inventory is more than a back-office task—it’s the heartbeat of every job. When your materials are tracked, your crews stay efficient. When they’re not, delays, mistakes, and added costs pile up fast. The right inventory software doesn’t just fix a process—it brings clarity to the whole operation, helping you stay on top of what you have, what’s needed, and where it’s going.

Whether you're managing a few service vans or coordinating large commercial installs across multiple sites, connecting inventory with scheduling, quoting, and billing gives you the control you need to run a tighter ship. Platforms like BuildOps are built to support that kind of integration—especially for commercial field service teams that can't afford to guess when it comes to materials.

BuildOps for plumbing contractors

Combine inventory management with every part of your plumbing service process.