One bad bid can blow the budget on a whole project. That’s the reality for electrical contractors handling installation work. Whether you’re quoting a panel upgrade for a new build or wiring a multi-unit commercial space, the numbers on your estimate aren’t just guesses—they’re the difference between staying profitable and bleeding hours on change orders.

This guide lays out what it really takes to build accurate electrical installation estimates. We’re not just talking about wire and breakers—we’re digging into the labor, logistics, permitting, and overhead that most bids forget to fully capture. For electrical pros leading crews in the field, understanding electrical installation estimating and costing means fewer missed line items and stronger margins.

If you’re working in the electrical industry, or looking to sharpen how your team builds quotes, this guide is built to help you cut through the noise and estimate like a pro. Here’s what you’ll find inside:

- 6 electrical installation pricing methods contractors actually use

- Key costs that drive electrical installation estimating and costing

- How to build an accurate electrical installation estimate

- Real-world examples of electrical installation and estimation in action

- How to avoid underbidding on electrical installation jobs

Getting your numbers right sets the tone for the entire job. In the next section, we’ll break down the different estimating methods electrical contractors rely on—so you can find the one that fits how your crew works.

6 electrical installation pricing methods contractors actually use

Every shop has a different approach when it comes to electrical installation estimating and costing—and for good reason. What works for a basic service call won’t cut it on a multi-floor build-out with gear terminations and utility coordination.

Picking the right pricing method gives you control over your numbers, protects your margins, and helps your bids hold up once boots hit the ground. Here are six pricing methods electrical contractors use, and where each one fits:

- Flat rate – You charge a fixed amount for a defined scope of work. This method works best for repeatable installs like lighting circuits, panel swaps, or outlet runs. It simplifies quoting and billing, but you need solid historical data to make sure your flat rates actually reflect real labor and material usage.

- Time and materials – Ideal for open-ended installs or when the scope isn’t fully defined. You bill based on actual hours and material usage. Works well for emergency jobs, change orders, or retrofit installs in older buildings. But you’ll need clean tracking to avoid billing issues or missed costs.

- Tiered pricing – This model bundles install tasks into basic, standard, or premium packages. A basic tier might include rough-in only, while the premium tier covers device trims, gear terminations, testing, and labeling. It’s a good fit for service teams offering upgrades or turnkey install options.

- Subscription-based – You offer ongoing electrical services under a monthly or annual agreement. This works well for property groups needing regular inspections, lighting upgrades, or compliance testing. It helps keep your schedule full while building predictable revenue.

- Cost-plus – You calculate the full cost of labor, gear, conduit, and project overhead, then add a markup. It’s commonly used on larger installs where pricing flexibility is needed. You’ll need detailed takeoffs and consistent tracking to keep margins from slipping.

- Value-based – This method prices based on the value delivered, not just the hours worked. Got a crew that can complete a shutdown and switchover in a single weekend? Or handle complex coordination with utility services? This model captures the premium your team brings when timing and precision matter.

Each method has a place depending on job size, crew capability, and scope complexity. Most electrical shops blend two or three depending on the project type. Next, let’s get into the real numbers—what it actually costs to build a complete electrical installation estimate.

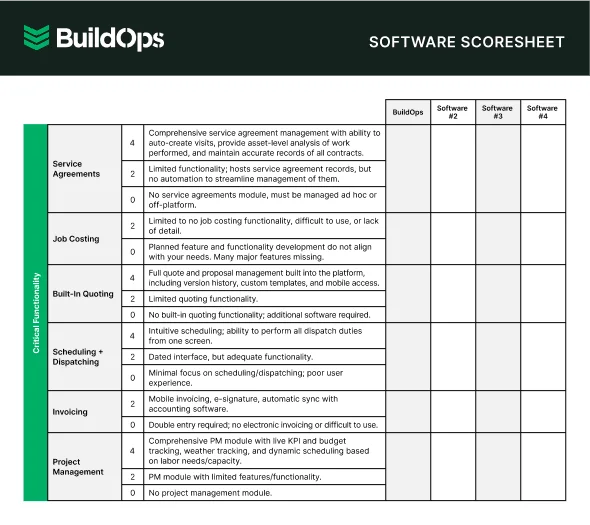

Easily compare software tools

See how the leading providers stack up so you can find the ideal tool.

Key costs that drive electrical installation estimating and costing

Accurate numbers don’t start with a guess—they start with knowing every cost that hits your job before the first box of wire even lands on-site. With electrical installation estimating and costing, it’s not just about breakers and conduit. Every task, tool, and trip to the supply house factors into your margin.

Contractors who consistently build reliable quotes usually have a process rooted in field data and full-scope tracking. That includes everything from labor hours and material pricing to overlooked indirects like permitting or rental gear. If you’ve ever built out a cost estimating breakdown for electrical work, you know the biggest misses aren’t always in the panel—they’re often in the background costs most bids ignore.

If you're building a solid electrical installation estimate, you need to price in the full load—not just what’s visible on the bid. Here’s what contractors track to make sure the numbers hold when the work starts:

- Labor – Time is everything. What’s the real effort to get the job done? That includes setup, cleanup, and navigating tight installs. Are you sending journeymen or apprentices? Running circuits in an open ceiling or core-drilling a slab? Labor needs to reflect scope, skill, and site conditions.

- Material and gear – Wire, conduit, breakers, terminations, panels—costs swing fast based on copper pricing and supply chain gaps. Your electrical installation estimate needs to include material buffers and supplier lead time risks, especially when quoting months ahead of the install date.

- Travel and site access – Fuel, mileage, parking fees, and windshield hours add up fast. Multiple mobilizations? Hard-to-access high-rises? Your quote needs to factor in the cost of just getting your crew to the work—especially for service-based install teams running tight windows.

- Tool wear and rentals – Rotary hammers, benders, lifts, test meters—they don’t last forever. Each job takes a bite out of your tool inventory. Rental equipment, tool replacements, or specialty gear (like GPR scanners or megohm testers) should show up in the costing.

- Urgent response premiums – Fast-tracked installs, last-minute shutdowns, or after-hours work demand premium pricing. If the GC needs a lighting circuit pulled same-day, that changes the rate. The same goes for hospital or data center work where downtime isn't an option.

- Unexpected delays – Slab coring issues, missing sleeves, coordination gaps with other trades—all of it burns time. Build a buffer into your electrical installation and estimation to account for jobsite realities that rarely go as planned.

- Overhead – Your office admin, scheduling software, insurance, licensing, jobsite radios—it all costs money. Just because it doesn’t show up on the invoice doesn’t mean it’s not part of the job. Many shops shortchange themselves here and pay for it later.

- Permit and compliance fees – AHJ plan reviews, city permit costs, arc flash labeling, utility tie-ins, and energy code compliance all affect install costs. Skipping this category puts you at risk for lowballing jobs that end up bleeding on closeout.

By keeping tight control over these categories, your electrical installation estimating and costing won't just protect your margin—it’ll keep your bids competitive and your crew covered once work starts. Up next, we’ll walk through how to actually build a quote step-by-step, using real jobsite inputs to shape a reliable electrical installation estimate.

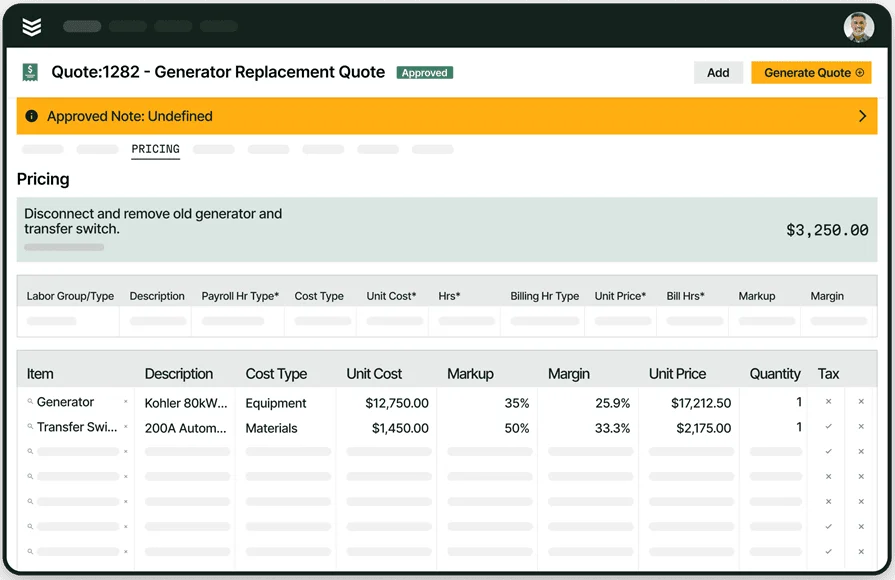

Built-in electrical estimating

Tie estimates to scheduling to work done to invoices out—all in one tool.

How to build an accurate electrical installation estimate

Strong electrical installation estimating and costing isn’t guesswork—it’s a process. The most reliable contractors aren’t just winging it or copying the last bid. They’re using repeatable steps to lock in real job costs, protect margins, and avoid the kind of surprises that kill profit during closeout. Whether you’re quoting a full panel upgrade, a core-and-shell install, or multi-site tenant work, here’s how to build an electrical installation estimate that actually holds up once the work starts:

1. Lock in your baseline job costs

Start with the costs that never go away—labor, conduit, wire, boxes, tools, gear, fuel, insurance, and indirects. Every dollar leaving your business needs to be accounted for. Don’t just think about what goes into the walls—include what it takes to get your crew there, keep them equipped, and manage the job from start to finish.

2. Factor in your local market

Take a hard look at what other contractors are charging in your area for similar scopes. Local pricing shifts based on utility coordination, AHJ fees, and even union labor rates. Staying competitive means your pricing reflects real demand and expectations in your territory—not just what your spreadsheet says. For service-heavy work, reviewing how your competition handles quoting, dispatch, and billing gives you a sharper edge. Tools like electrical dispatch software can help keep your crew scheduling in sync with quoting workflows.

3. Choose the right pricing model for the job

Not every install needs the same pricing structure. Cost-plus works for complex gear upgrades, while flat rate might suit small tenant fit-outs. Package pricing can help when offering service tiers to facility groups. Match the pricing model to the install type, duration, and level of complexity. Your quoting system should support different methods depending on the job flow.

4. Build your quote using actual site conditions

Don’t quote blind. Walk the site, check drawings, inspect panel locations, and flag ceiling heights or slab work. Calculate wire runs, labor time, material drops, and gear delivery needs based on job-specific factors. For large-scale or ongoing client work, platforms that include electrical inventory management can help you stay ahead of material delays and shortages as you quote.

5. Invoice as soon as the work wraps

Delays in billing equal delays in payment. When installation work wraps, the invoice should follow fast. Whether it’s phased billing or milestone-based draws, tight turnaround on invoicing helps protect your cash flow. Learn more about the electrical contractor invoicing guide to make sure your workflow supports fast billing across install types.

6. Review each job and refine your next estimate

Once the job’s closed out, compare what you estimated with what really happened. How many hours did it take? What delays hit you on-site? How much gear got returned? Tracking this feedback sharpens your next quote. Estimators using tools like the best CRM for electrical contractors can connect job outcomes back to their quoting assumptions, so they’re not guessing on the next one.

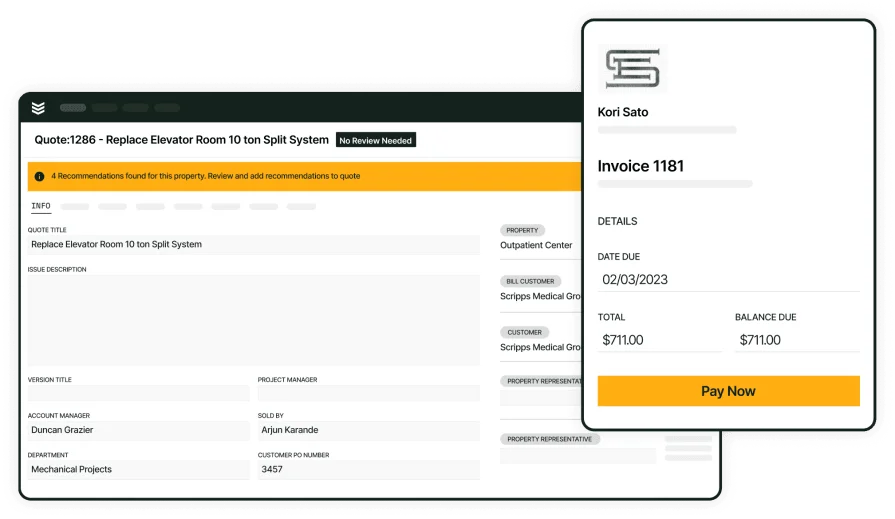

Quote jobs precisely

Streamline the estimating process so you can quote jobs accurately.

Building an electrical installation estimate that holds up in the field means starting with real costs and ending with real feedback. Each install gives you data. Use it. Adjust. Quote sharper next time.

Real-world examples of electrical installation and estimation in action

Good estimating doesn’t happen in isolation. If you’re bidding a new install, upgrading gear, or coordinating with a GC on a large-scale project, your pricing needs to reflect real job conditions. Understanding how electrical installation and estimation plays out across different job types helps keep your numbers sharp and competitive.

Here’s how the process typically looks on the ground:

1. Tenant buildouts

A commercial tenant space needs panel work, lighting circuits, and sometimes fire alarm or data drops. These installs usually land between $5,000 and $25,000 depending on square footage and specs. Your electrical installation estimate needs to reflect not just the fixture count, but also switchgear lead times, ceiling access, and site coordination with HVAC and plumbing crews. Delays in ceiling framing or slab coring can impact everything—building in those variables upfront keeps your quote accurate.

2. Retail and franchise installs

Franchise chains demand consistency, speed, and clean documentation. Whether it's a coffee shop or a gym location, you're often dealing with strict specs, compressed timelines, and repeat layouts. These projects highlight the value of a tight service order management process—so you can replicate installs without reworking your estimate from scratch every time.

3. Healthcare and critical systems

Hospitals, labs, and clinics often require redundant feeds, emergency circuits, and zero room for error. Permits, inspections, and after-hours work are standard. Electrical installation estimating and costing here must factor in testing, labeling, backup systems, and tighter safety compliance. Your bid should reflect the real cost of precision work—including utility coordination and job sequencing around patient areas.

4. Warehouse and industrial installs

Large facilities with lift stations, machinery hookups, and high-bay lighting require upfront planning and durable quoting. You’re managing long conduit runs, elevated work, and often a mix of existing infrastructure and new feeds. A clean contractor dispatch management setup helps your crew stay productive across sprawling sites where job sequencing is key.

5. Multi-site or recurring installs

National retailers or property groups often need installs across several buildings or locations. The challenge? Quoting at scale without losing accuracy. Smart teams rely on field service operations systems to maintain consistency while adapting to site-specific needs. Your electrical installation and estimation approach needs to account for material delays, permit variations, and crew allocation across jobs that roll out simultaneously.

6. Closeout and invoicing

After the install’s done, collecting payment quickly depends on clean documentation. Projects that include final walkthroughs, as-builts, and detailed electrical work order invoice support closeouts that don’t drag. Inconsistent billing or delayed handoff kills momentum. Your estimate should tie into how you bill—job phases, milestones, or fixed delivery points.

Expert Tip

The way your team documents the job, tracks changes, and closes the loop makes all the difference in estimating. Tools like field service reporting give you the jobsite data you need to back your numbers—and build stronger bids next time around.

How to avoid underbidding on electrical installation jobs

Underbidding doesn’t always come from bad math. It usually comes from missing the full scope of what the job demands. When your electrical installation estimating and costing process skips over key items—travel time, permit runs, tool wear, or last-minute reroutes—you eat those costs later.

Here’s how contractors keep that from happening:

1. Track every direct and indirect job cost

Losing margin usually starts with the small stuff: fuel, parking, delivery charges, gear rental, lost time on-site, or tech admin hours. If your electrical installation estimate only accounts for parts and labor, you’re already behind. Use job data from tools like a contractor estimate app to track what each job actually costs to run—from dispatch to closeout.

2. Set rate floors that protect your profit

A clear pricing floor gives your team confidence when bidding and protects the business from quoting work that can’t pay the bills. Update these floors as your labor costs shift, especially with wage increases or insurance hikes. For electrical installation and estimation to stay accurate, your quoting system should reflect seasonal shifts, material pricing, and install-specific factors. Connect your rates back to real numbers tracked through accounting software for electrical contractors that reflect real-time changes in job costs.

3. Benchmark—don’t copy—the competition

Seeing what other contractors charge in your area helps, but it shouldn't define your price. Your rates should reflect how fast and well your crew can get the install done, what tools you use, and how you manage risk. Just because someone’s quoting lower doesn’t mean they’re covering their costs. Let your quality, speed, and tech use shape your pricing.

4. Use job history to shape your quotes

Every job your crew finishes adds data. Job time, materials used, delays, callbacks—all of it builds a record you can use to refine your next bid. With strong CRM software for small business contractors, you’re not guessing—you’re quoting based on how similar jobs actually played out. That’s where electrical installation estimating and costing goes from reactive to reliable.

5. Audit your pricing regularly

Costs shift—wages, copper pricing, equipment updates, utility rules. If you’re still quoting based on last year’s spreadsheet, you’re probably leaving money on the table. Schedule routine pricing reviews, and if you’re using standard billing formats, review your electrical contractor invoice examples to make sure they still reflect your true job structure and profit goals.

Protecting your margins starts before the bid ever goes out. The better you track your numbers, the fewer jobs you’ll land that burn you on the backend. Strong electrical installation and estimation isn’t about playing it safe—it’s about quoting with your eyes open.

Good estimating starts with knowing the job, not just the numbers. Electrical installation estimating and costing takes a full view of the work—labor hours, gear runs, mobilization, coordination, and every hidden charge that shows up on-site. The crews that stay profitable are the ones quoting with precision, backed by real field experience.

When you're handling installs across multiple commercial jobs, the paperwork piles up fast. An all-in-one platform built for electrical field service helps you quote with accuracy and manage what comes after—dispatching, tracking, and billing—without gaps or guesswork. Reliable estimating sets the job up right. Reliable systems keep it on track.

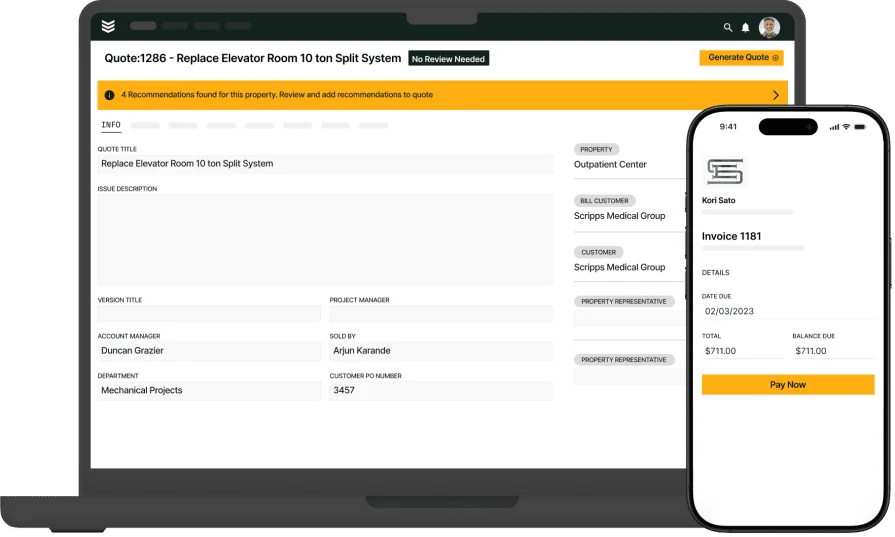

Check out BuildOps in action

See how we support your install workflow—from the first estimate to closeout.