In electrical contracting, juggling tools, parts and materials, and purchase orders without a system in place creates delays and drains profits. Materials at the wrong time can grind a project to a halt, whether you're stocking up for high-volume jobs or tracking items across trucks and warehouses. That’s where purpose-built inventory software comes in—giving electrical contractors more control over their inventory.

Keeping your electrical inventory management system organized is about more than tracking—it’s about unlocking better job flow and cost control. With 50% of electricians surveyed reporting growing demand from data centers, according to The Pivot Point, a report by BuildOps, leveraging tools to uplevel your business is the key to taking advantage of highly profitable hot markets.

In the electrical industry, inventory management is all about finding the right software and tools that can bring your whole operation into sync. To help you discover what those are, we’ll cover:

- Choosing the right electrical inventory management software for your team

- 6 key features to look for in an inventory management software for electrical contractors

- 8 best electrical inventory management software solutions for contractors

- 7 benefits of using an electrical inventory management software

- 4 important electrical inventory management software FAQs answered

Before we dive into tools and features, let’s look at what really matters when evaluating software—and the key questions your crew should be asking before locking into a solution.

Choosing the right electrical inventory management software for your team

Choosing software shouldn’t feel like guesswork. For electrical contractors, it's about finding a system that fits how your crew works—from the warehouse to the job site. Before locking in a solution, step back and ask the questions that matter. What’s slowing down your material handling? Where are things getting lost? The answers will shape what kind of platform will actually move the needle.

- What is our project volume and job types? Determine how many active projects teams manage at once, and the kind of material required by them. ? Are the materials similar per job? Or are they more specialized and varied? Decide whether you need technology that can handle commercial jobs with complex materials or smaller service calls that turn quickly.

- What teams and roles need to be involved? Figure out who’s in charge of tracking and updating inventory. Are they warehouse leads, service managers, or techs in the field? Determine whether the software needs to work across multiple teams and be accessible on mobile devices.

- What is our current inventory process? Determine how inventory is managed today, whether it’s through spreadsheets, whiteboards, or another basic system. Figure out the biggest points of failure in how parts and materials are tracked in the current system.

- Will the solution need to integrate with other systems? Think about the company as a whole and determine whether the inventory platform needs to sync with scheduling, accounting, or field service tools. How much of the workflow depends on connected systems working together?

- What additional features are required? Review current procedures to figure out what else might be required for seamless software integration. Do you need real-time stock updates? Can you assign materials to specific jobs or trucks? Does the platform support barcode scanning or bulk uploads? With 30% of contractors surveyed in The Pivot Point saying fragmented systems are slowing them down, making sure software solutions integrate with current systems to fully leverage the power of technology.

Deep Dive

If you’re looking to find more efficiency in or completely overhaul your current system, check out our full guide to electrical inventory management, including 10 actionable best practices specifically for electrical contractors.

Before we get into specific features, it’s worth looking at which tools actually help crews work faster, stay organized, and cut waste while improving productivity and profits—and which ones just add complexity without real value.

6 key features to look for in an inventory management software for electrical contractors

Inventory issues aren’t always about what’s missing—they’re often about what’s untracked. For electrical contractors, lacking tools to properly track inventory in the warehouse, services trucks, and on jobsites can mean wasted time, missed revenue, and delays that throw off the whole schedule. The best inventory management software helps you keep tabs on every fitting, cable spool, or breaker, without turning your techs into data-entry clerks. Here are the core features electrical contractors need to stop guessing and start taking control.

1. Invoicing and purchasing visibility

Inventory starts and ends with transactions. A solid inventory platform should connect data about every tool, part, and material directly to invoicing and purchase orders—tracking what goes out, what comes in, and what it costs. Let’s say your team is wrapping up a retrofit and logs four smart switches used on the job.

When your inventory system syncs with field service invoicing tools, those switches are automatically deducted from stock, tied to the invoice, and flagged for reorder if supply gets low. Because the tracking is automatic, field techs spend more time working and less time doing tedious data entry.

And tracking becomes more reliable and accurate because there’s no risk of human error. The automatic link between field usage and financials keeps your stock accurate, your billing clean, and field techs productive.

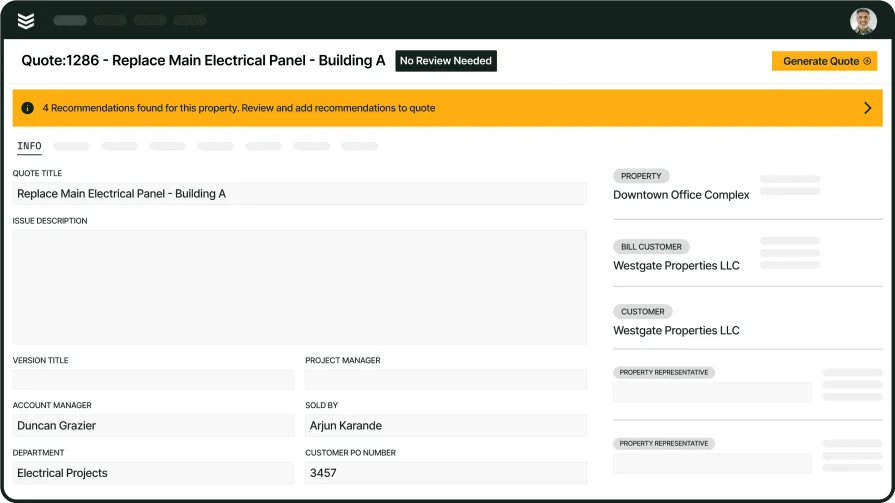

2. Connected pricebook management

If your team is pricing materials off a static sheet—or worse, guessing—you’re setting yourself up for inconsistent margins. That’s why inventory tools should pull live data from your material pricebook and reflect accurate, job-ready rates.

Customers receive more-accurate quotes because estimates use real-time data on inventory pricing based on a built-in catalog pulls in parts and pricing. During a tenant improvement buildout, your estimator selects a batch of receptacles and conduit directly from a connected quoting system that talks to the inventory tool.

The customer is billed accurately, the warehouse knows to order more parts, and leadership gets a birds-eye view into what types of materials are used on each job, as well as how pricing fluctuates over time for better forecasting.

3. Mobile inventory access for field crews

A desktop-only system doesn’t help a journeyman on-site with gloves on. Field-ready inventory access lets techs pull materials, update usage, or confirm availability straight from their phones—without calling into the office. When they use materials, the inventory system updates automatically for real-time data on company-wide inventory levels. If they need materials, they can check availability immediately without wasting time checking with the warehouse.

Say a tech is wiring lighting zones in a commercial kitchen and runs short on THHN. Instead of pausing work, he checks his phone, confirms inventory in the warehouse, and requests a same-day drop. With access to a mobile field tech app, your crew stays productive and your material data stays accurate in real time.

4. Inventory tracking across trucks and warehouses

Parts don’t stay put—and if your software can’t handle multiple storage locations, you’ll always be one step behind. Good inventory systems track tools and materials across job sites, trucks, and the warehouse. Take your service van fleet. One tech is short a GFCI, but another van parked at the same site has extras. Because the system logs items by vehicle using fleet management inventory tracking, the office can reassign materials without wasting time or sending someone back to the warehouse.

Insight into what materials are in what vehicles allows managers to keep the fleet stocked at all times. Techs show up ready to work, not doubling checking that the right materials are in the vehicle for each job.

High-level inventory tracking also prevents tools, materials, and parts from going missing or sitting on the shelf forgotten about. Management can view where each part is, whether it’s the van, job site, warehouse, to make sure crews have what they need when they need it. They avoid over-ordering from a lack of full inventory data, saving money and avoiding waste.

5. Job-based material assignments

You wouldn’t send a crew out without a job scope, so you shouldn’t send them without a parts list. Assigning materials to jobs in advance ensures nothing is missed, and that what’s pulled matches what’s needed. Management can make sure techs are well-supplied with all parts and materials they need for every job on their schedule.

For example, when planning a school lighting upgrade, the warehouse manager can use the system to build out material kits per room. Those parts are tagged to the job and deducted once picked. The inventory list is automatically updated, and the manager can determine whether another order of parts is required.

With field service scheduling tools that connect to inventory, your jobs stay tight and your techs roll out fully prepped every day, regardless of job complexity

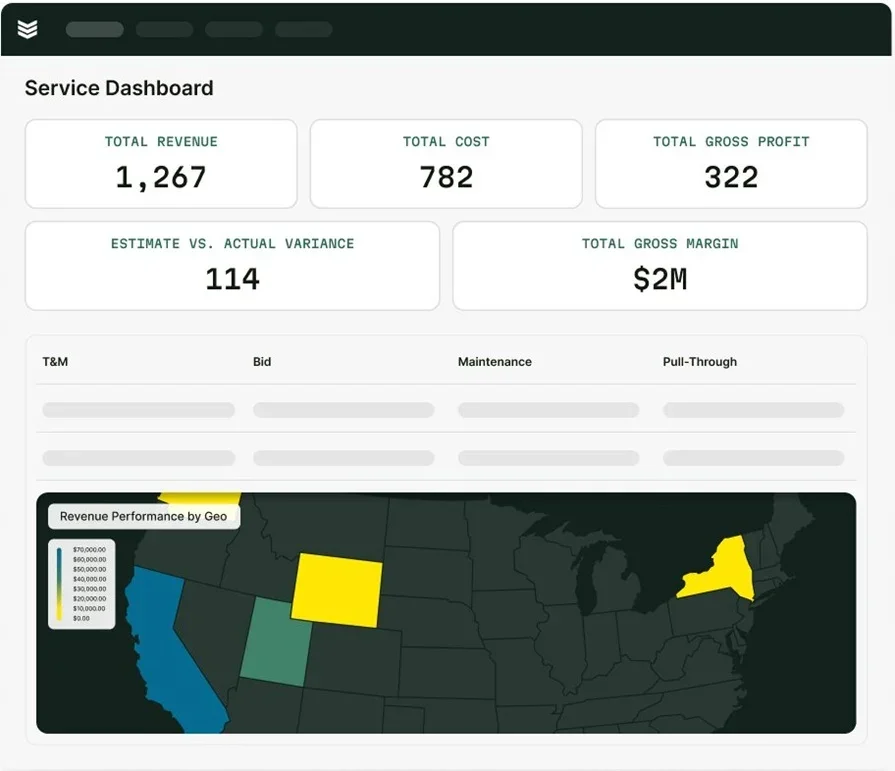

6. Inventory usage reporting

High-level inventory tracking provides forecasting and reporting that can identify patterns for better business management. Reporting tools give insight into fast-moving parts, underused stock, and seasonal trends. Inventory managers can review that data to make better decisions about purchasing, keeping all jobs on track throughout the year without wasting money on over-ordering.

For example, when reviewing Q1 inventory usage, you notice a spike in outdoor-rated junction boxes tied to generator installs. That trend, visible through customer inventory dashboards in your field service reporting tool, helps you order ahead before peak season hits again—and avoid job delays from supplier shortages.

Service Work Toolkit for Electrical Contractors

Learn how to connect parts, jobs, and billing—all in one platform.

There are also a few additional useful features that—while not inventory-specific—still help support inventory flow and field operations when they’re connected to the system.

Other valuable features to look for in electrical inventory management software

While these features aren’t core to inventory tracking, they play a supporting role in keeping your materials organized and your jobs on track. When they connect with your inventory system, they reduce manual work, improve accuracy, and help every part of your operation stay aligned to improve electrical contractors' bottom lines. Tools that tie into business management software help contractors scale, arming them with the control needed to take advantage of opportunities for growth.

- Time tracking integration: When time tracking tools are connected to your inventory system, it’s easier to align labor hours with material usage. You can break down inventory used by each technician and review usage trends to help with job costing, planning, and spotting inefficiencies tied to part consumption.

- Customer insights through CRM: A CRM tool for electrical contractors lets you track service history and inventory trends per client. It helps anticipate material needs and cuts prep time for recurring work.

- Service agreement tracking: With service agreement features tied to your inventory platform, you can preload jobs with contract-specific materials based on real-time pricing and forecast recurring usage based on agreement terms.

- Payment flexibility: When payment tools integrate with inventory data, materials used on the job automatically sync to invoices. That means every part and material used automatically goes to billing, making sure nothing slips through the cracks. That reduces errors and waste, increases profits, and speeds up closeout and collections.

- Opportunity tracking and quoting: Sales and pipeline software can help forecast demand before jobs land. Connecting this to your inventory system supports proactive purchasing and long-term planning.

When your inventory platform works hand-in-hand with quoting, time-tracking, service agreement, reporting, CRM, and payment tools, it creates a tighter, more connected workflow. Data from integrated software that shows the big picture provides information electrical contractors need to stay competitive, productive, and win more bids.

Up next: a detailed look at the top inventory software options out there—and how they stack up.

8 best electrical inventory management software solutions for contractors

Not all inventory software fits the way electrical contractors work. Some tools are built for speed, others for scale. Here’s a breakdown of the top options—and where each one stands out (or falls short) depending on the type of work you do.

1. Best for commercial: BuildOps

BuildOps is purpose-built for commercial contractors who manage complex inventory across multiple job sites and vehicles. Its platform gives real-time visibility into materials, ties usage to jobs automatically, and connects seamlessly with quoting, invoicing, and dispatch. The interface is clean, mobile-ready, and built specifically for field crews who need quick access to the right parts without clicking through layers of menus. For businesses aiming to scale up, this platform is purpose built for growth.

How pricing works: BuildOps offers custom pricing based on company size and features needed.

Features beyond inventory management: Includes technician time tracking, advanced reporting, CRM, estimating, mobile app access, and robust service agreement management.

What sets it apart for commercial: Designed for scale. Whether you're running five techs or fifty, it supports high-volume, multi-crew workflows with no performance lag.

An end-to-end electrical contractor platform

Tie together inventory, dispatching, scheduling, and billing, in one platform.

2. Best for residential: Housecall Pro

Image Source: Housecall Pro

Housecall Pro is designed with simplicity in mind. It’s user-friendly and works well for smaller residential service businesses that don’t need heavy customization. The interface is clean, and it handles job scheduling, payments, and customer communication with ease. However, it lacks deeper inventory control features and may not scale well for contractors managing multiple crews or high material turnover.

How pricing works: Tiered pricing with core features starting around $59/month. More advanced tools require higher-level plans.

Features beyond inventory management: Includes online booking, job tracking, payment processing, and automated marketing for customer follow-ups.

What sets it apart for residential: Easy for solo contractors or small teams to get up and running quickly with minimal setup.

Check out our breakdown on how BuildOps stacks up against Housecall Pro for electrical inventory management and other field service operations.

3. Best for general contractors: Workiz

Image Source: Workiz

Workiz offers a broad feature set that covers dispatching, invoicing, and basic inventory tracking. Its strength is in field service management for mixed-trade teams, including electricians, plumbers, and handymen. The platform is flexible but not deep—especially when it comes to advanced inventory needs like multi-location tracking or job-based part assignment.

How pricing works: Plans start around $65/month per user, with pricing increasing for added automation and integrations.

Features beyond inventory management: Provides a customer portal, call tracking, custom forms, and lead management tools.

What sets it apart for general contractors: Offers versatility for contractors juggling multiple service types and client needs under one platform.

4. Best for small teams: Xero

Image Source: Xero

Xero is best known for its accounting software, but it also includes a simple inventory module that small electrical contractors can use to track stock levels, assign parts to invoices, and keep tabs on item costs. It’s not built for complex job workflows, but for tight teams focused on clean books and basic material tracking, it gets the job done.

How pricing works: Starts at $2.90/month for basic features; inventory management is included in all paid plans.

Features beyond inventory management: Strong accounting tools, invoicing, bank reconciliation, and payment tracking.

What sets it apart for small teams: Great for contractors who want basic inventory tools built directly into their accounting system—without needing another platform.

5. Best for businesses looking for free tools: Zoho Inventory

Image Source: Zoho

Zoho Inventory offers a surprisingly deep feature set at zero cost for smaller users. It supports multi-warehouse tracking, order fulfillment, and barcode scanning—making it a solid option for small electrical shops that want to upgrade from spreadsheets without spending upfront. However, it’s not trade-specific, so some customization may be required.

How pricing works: Free for businesses with fewer than 50 orders/month. Paid plans start at $59/month.

Features beyond inventory management: Order management, multi-channel sales integration, shipping tools, and automation features.

What sets it apart for businesses looking for free tools: It’s one of the few no-cost options that still supports robust inventory features like multi-location control and real-time stock visibility.

6. Best for visual inventory tracking: Sortly

Image Source: Sortly

Sortly stands out with a clean, visual approach to inventory—ideal for electrical contractors who prefer simple item organization and photo-based tracking. It supports tagging, barcode scanning, and mobile access. However, it may not go deep enough for those needing advanced job costing or integrations with quoting tools.

How pricing works: Free plan available; paid plans start at $49/month.

Features beyond inventory management: Mobile app, folder-based asset organization, custom tags, and activity logs.

What sets it apart for visual inventory tracking: Great for field teams who want to see and manage their inventory in a more intuitive, image-driven format.

7. Best for warehouse-centric operations: inFlow Inventory

Image Source: inFlow

inFlow Inventory is tailored for businesses with large stock volumes and structured warehouse environments. It supports order tracking, vendor management, and barcode scanning—making it a solid choice for electrical contractors with centralized storage and regular restocking needs. It’s less suited for highly mobile crews without a fixed hub.

How pricing works: Plans start at $89/month with full inventory features.

Features beyond inventory management: Purchase orders, sales tracking, vendor catalog management, and reporting dashboards.

What sets it apart for warehouse-centric operations: Its depth in warehousing workflows helps streamline part movement and procurement across mid-sized and growing teams.

8. Best for integrated retail and inventory: Square POS

Image Source: Square

Square’s inventory feature is part of its larger point-of-sale system, but it works well for electrical shops that also run counter sales or maintain a small storefront. While it’s not designed for field dispatch, it tracks item counts, adjusts stock in real time, and supports barcode-based checkouts.

How pricing works: Free to start, with transaction fees and optional add-ons.

Features beyond inventory management: Point-of-sale system, customer directory, team permissions, and sales reporting.

What sets it apart for integrated retail and inventory: Perfect for contractors who sell materials or parts and want to connect inventory directly to their storefront activity.

7 benefits of using an electrical inventory management software

Electrical contractors deal with tight schedules, material shortages, and rising job costs. Inventory management software helps fix the root of those problems—by giving you better control over materials, improving communication between the field and office, and keeping your costs visible at all times.

1. Accurate billing from the first pull to the final invoice

When material usage is recorded as it happens, and automatically reflected in billing, you eliminate missed charges and errors. You charge customers for parts and materials with 100% accuracy, every time. Inventory software connects material data directly to job records, so everything that leaves the shelf is accounted for. You don’t rely on technicians to remember all parts and materials used, and then update the office, who then bills the customer.

There’s no more back and fourth, and billing improves. This significantly cuts down the time it takes to actually get invoices out, especially when techs can record the materials used in real-time on jobsites. The faster a bill goes out, the more likely it is to get paid in a timely manner. An invoice sent in 10 days typically gets paid in 50-53 days, while an invoice sent in 28 days typically gets paid in 86 days. That’s a gap contractors can’t afford.

Expert Tip

The accuracy you get from inventory tracking connected to billing becomes even more powerful when you pair it with structured invoice templates that you can use across different projects—customized for your most frequent use cases. Check out our list of the best electrical contractor invoice templates to learn how to do this, and why templates built right into your software are better for operational efficiency.

2. Faster turnaround with better customer communication

With live inventory access, office staff and field techs can confirm part availability instantly—speeding up quotes, job approvals, and dispatch decisions. This visibility improves the customer experience and helps avoid delays tied to material questions. Technicians can finish the job quickly and efficiently, resulting in happier customers.

Paired with effective CRM tools for electrical contractors, it creates a smoother, more professional interaction from the first call to job completion.

3. Fewer job delays from part shortages

When techs show up missing a part, schedules fall apart. When crews manage multiple technicians visiting a number of jobsites each day, something is bound to slip through the cracks without a strong grasp on inventory management.

Software that syncs with job planning and truck stock helps ensure every item is in place before crews roll out. You reduce supply house runs, idle time, and missed appointments. The right dispatching process for electrical teams relies on this kind of inventory coordination to stay efficient and increase productivity.

4. Less waste and better purchasing decisions

Inventory data shows what’s moving—and what’s not. That helps electrical contractors cut down on dead stock, avoid overordering, and negotiate better with suppliers. Managers better understand their inventory, ensuring they don’t order parts hiding on the back of a shelf or over order materials due to lack of oversight.

Reducing material waste saves money, frees up space and tightens operations. It aligns with smarter field service strategies that keep crews focused and budgets under control.

5. Better job profitability insights

Knowing what materials were used on each job helps teams measure profitability accurately. When parts are tracked at the task level, project managers can quickly spot overages or cost leaks. Without inventory software, those insights are often missed. High-level reporting powered by inventory management software layers in job cost data provide the full picture of margin performance across service calls and installs. That level of insight allows managers to make strategic decisions about inventory, scheduling and jobs.

6. Clearer accountability for material use

Tracking who pulled what—and when—helps eliminate confusion and keeps teams honest. If a part goes missing or usage looks off, you’ve got the logs to review. Nothing slips through the cracks because all parts and materials are tracked, whether they’re in the warehouse, loaded in a van, or on the jobsite. This kind of transparency improves trust between field and office, and supports consistent restocking across trucks and warehouses.

7. Smoother coordination among teams

Inventory software creates a central system that connects your warehouse, office staff, and field crews. Everyone sees the same stock levels and job assignments, reducing communication gaps. When these tools are built into your field service process, the entire operation runs with less friction and more predictability. Technicians are confident they have the tools they need, customers are happy the job is completed quickly, and business owners know they’re operating efficiently and profitably.

The benefits really start to add up when material tracking is connected to scheduling, customer management, quoting, invoicing, and reporting. Up next, we’ll cover the common questions electrical contractors ask when looking at inventory software—and what to consider before making the switch.

4 important electrical inventory management software FAQs answered

Choosing inventory software isn’t always straightforward—especially when your team is juggling installs, service calls, and supplier relationships. These FAQs break down the most common questions electrical contractors ask when it comes to inventory tools, billing accuracy, and real-world implementation.

1. What is electrical inventory management software?

Electrical inventory management software is a digital system that electrical contractors use to create, track, and organize parts and materials. Technicians or office staff enter parts and stock information once, and the system automatically updates inventory levels as items are used in the field.

This reduces data entry errors and eliminates most of the manual work of tracking parts on every job—especially the small, high‑volume items that are hardest to manage. It can also tie inventory directly to invoicing, cutting down on office admin and helping you bill more accurately, faster.

2. How does inventory management software for electrical contractors work?

Inventory management software helps electrical contractors track, assign, and restock parts across warehouses, trucks, and job sites. It gives teams real-time visibility into what’s on hand, what’s been used, and what needs to be reordered—all from a centralized system.

The software streamlines the flow of materials from warehouse to field, helping teams avoid shortages, reduce waste, and stay on budget. Here’s how it typically works:

- Tracks part quantities across multiple locations (warehouses, vans, jobsites)

- Logs material usage in real time, often through mobile apps

- Assigns specific materials to work orders or service calls

- Updates inventory counts automatically when items are pulled or restocked

- Connects with purchasing to reorder parts when thresholds are hit

- Links inventory data to invoices for accurate billing

- Supports barcode scanning for faster check-in and check-out

- Flags low stock and surplus to improve purchasing decisions

- Provides usage history for audits and job costing

- Syncs with other tools like scheduling, quoting, or dispatch for full operational visibility

The best types of electrical inventory management software are built into a platform as one component of a comprehensive electrician software, and typically offer other features that connect inventory to quoting, scheduling, billing, and other components of electrical field service work.

3. Is inventory management software worth the cost for electrical contractors?

Yes—and in most cases, it pays for itself faster than expected. For electrical contractors, the cost of disorganized inventory adds up quickly: missed parts on invoices, duplicate purchases, overstocked materials, and job delays from running short. Inventory software reduces those hits by keeping part counts accurate, connecting usage to specific jobs, and automating reorders before materials run out.

It also saves hours of manual tracking and communication between the field and office—giving teams more time to focus on actual work. When you add in tighter job costing and fewer rush orders, the return on investment becomes clear, especially for shops managing multiple crews or high material volume.

Did you know

Jomla Electric certainly thought the electrical inventory management software in BuildOps was worth the cost, because they gained much more value in time saved. They saw a 50% spike in efficiency once they made the switch.

4. What are some best practices to follow when implementing an electrical inventory management software?

Getting started with inventory software doesn’t have to be overwhelming. The key is to put in the groundwork that keeps your data clean, your materials visible, and your techs aligned. This checklist should help you get started with everything you need to track:

If you need some more detail, here are 10 proven best practices for electrical contractors rolling out a new system:

- Set minimum stock levels for fast-moving materials like wire, outlets, and junction boxes to avoid last-minute shortages

- Assign inventory by van or crew so each truck functions like a mobile warehouse and you know what’s being used, by whom

- Use clear labels and bins to organize parts and avoid lost materials—especially in trucks or shared spaces

- Schedule regular cycle counts instead of just annual audits to catch errors and low stock before they cause delays

- Link inventory to work orders to ensure material usage is logged automatically and accurately on every job

- Standardize kits for common service tasks like panel swaps or lighting upgrades to speed up prep and reduce leftover waste

- Centralize vendor and pricing info to streamline reordering and give your office staff better negotiating power

- Track tools along with materials to reduce loss, improve accountability, and avoid delays from missing gear

- Train your team to log usage and restocks consistently using mobile apps or barcoding tools

- Review usage trends quarterly to adjust your purchasing and avoid stockpiling slow-moving or rarely used parts

Following these steps helps you get the most out of your system and avoid the chaos that comes from flying blind.

For electrical contractors, inventory plays a bigger role in business success than most realize. From job prep to final billing, every part used and every restock affects profitability, timelines, and team performance. It allows contractors to chase larger contracts, because they’re supported by software that keeps the business on track. The software tools covered in this guide help eliminate guesswork, reduce waste, and give field and office teams a shared view of what’s really going on.

Many platforms offer pieces of this puzzle—but few connect them all. BuildOps brings it together with an all-in-one platform built specifically for commercial field service teams that want to improve productivity and become more efficient . Features like job-based part tracking, real-time stock visibility, and automatic invoice integration are built in so contractors can be sure every job is done well every time.

Demo electrical inventory management

See how BuildOps software handles inventory, quoting, dispatch, and billing in one system.