Every job in the field depends on knowing where your assets are, what condition they’re in, and who’s responsible for them. That’s the job of field service asset management—a critical piece of the larger field service management puzzle.

Whether it’s tools, fleet equipment, or customer-owned systems, asset management in field services helps contractors stay ahead of maintenance, reduce downtime, and avoid costly mix-ups. It’s how field teams keep jobs on track and operations tight.

In this guide, we’ll walk through what asset management field service looks like, how to build a system that works, and the best tools to help you do it. Here’s what we’ll cover:

- What is field service asset management?

- 10 steps to implement field service asset management in your company

- 8 field asset management best practices to enhance your operations

- Top 3 field service asset management software for contractors

Field service asset management involves more than just inventory; it ensures efficient field crews and satisfied customers through tasks like tracking serial numbers and scheduling preventive maintenance. Let’s break it down:

What is field service asset management?

Field service asset management is the process of tracking, maintaining, and organizing the multiple assets of your business—tools, equipment, and systems—used or serviced in the field. It combines asset visibility with field workflows to keep jobs running smoothly and reduce downtime across teams.

Managing assets in a field service environment is about more than logging serial numbers. It’s making sure field techs show up with the right gear, know the status of the equipment they’re servicing, and can access critical data on the fly. From HVAC units to company-owned tools, field asset management keeps jobs moving, crews accountable, and service levels high.

The importance of field service asset management for contractors

For commercial contractors, construction teams, and field service pros, managing assets isn’t optional—it’s survival. When you’re running multiple crews, dozens of tools, and high-value equipment across job sites, losing track of assets means lost time, missed deadlines, and extra costs. Field service asset management helps contractors take control of these moving parts so nothing gets overlooked or misplaced.

In fast-paced environments like HVAC, plumbing, and electrical, field asset management links directly to scheduling and dispatching. It ensures your techs show up with the right equipment and real-time information, minimizing return visits. It also connects tightly with inventory management—making it easy to track usage, schedule maintenance, and plan replacements before problems hit.

Contractors who manage their asset management field services through a centralized system stay organized, avoid costly surprises, and deliver better service. It’s not just about tools and trucks—it’s about keeping your business running efficiently job after job.

7 benefits of having automated asset management for field service teams

Automating your asset management field service process does more than cut paperwork. It gives your team real-time visibility into what equipment is available, what’s in use, and what needs service—right from the field. Having a field service asset management software helps techs move faster, work smarter, and avoid costly mistakes that slow down jobs or burn through budgets.

- Faster job readiness - Field crews can instantly confirm whether the tools and parts they need are available and in working condition before heading to a site.

- Reduced equipment loss - Automated tracking helps prevent misplaced or stolen tools by logging where each item is and who last used it.

- Lower maintenance surprises - Set up preventive maintenance schedules tied to real asset usage, reducing unplanned downtime in the field.

- Smarter inventory planning - With real-time asset data, it’s easier to forecast demand and avoid over-ordering or running out of critical parts.

- Better technician accountability - Each technician’s usage is logged automatically, helping managers identify trends or gaps in performance.

- Smoother dispatching and scheduling - Asset availability is tied to your job calendar, so dispatchers know what equipment is ready to roll for the next service call.

- Improved compliance and safety - Track service history, inspections, and certifications in one place—cutting risk and keeping your operation audit-ready.

Now that you’ve seen how automated field service asset management drives real value, the next step is learning how to set it up in your own business—without creating more chaos for your team. Let’s break it down into 10 simple steps to get started.

Explore our service management suite

We make sure technicians in the field have all the tools they need.

10 steps to implement field service asset management in your company

If you're serious about getting control over your assets in the field, you need more than a spreadsheet. This isn't a one-and-done process—it’s about building a system your team can rely on every day. Here’s how to actually do it from the ground up.

1. Start with a full asset audit

Before you can manage your assets, you need to know what you’re working with. Walk your yard, dig through your trucks, and list out every asset—equipment, tools, test instruments, anything used in the field. Log who uses it, where it’s stored, and its current condition. This creates your baseline and exposes immediate gaps in accountability.

2. Define what you need asset management to solve

Every business has different pain points. Maybe you're tired of losing tools, maybe you're bleeding money on untracked repairs, or maybe you need to prep assets for scheduled service. Set clear, specific goals around uptime, visibility, cost savings, and accountability. These goals will shape how you build and measure your system.

3. Choose a platform that supports how your team works in the field

Your crews need tools that match how they operate—mobile, fast, and responsive. The best platforms support real-time asset updates, integrate with job scheduling, and work without a signal. If you’re weighing your options, this field service software comparison guide breaks down how top tools stack up for field asset management.

4. Create a standardized tagging system for your assets

Whether you use QR codes, RFID, or barcodes, the key is consistency. Every asset should be tagged, labeled, and logged into your system with the same format. That way, your techs know exactly how to identify and scan tools in the field without second-guessing.

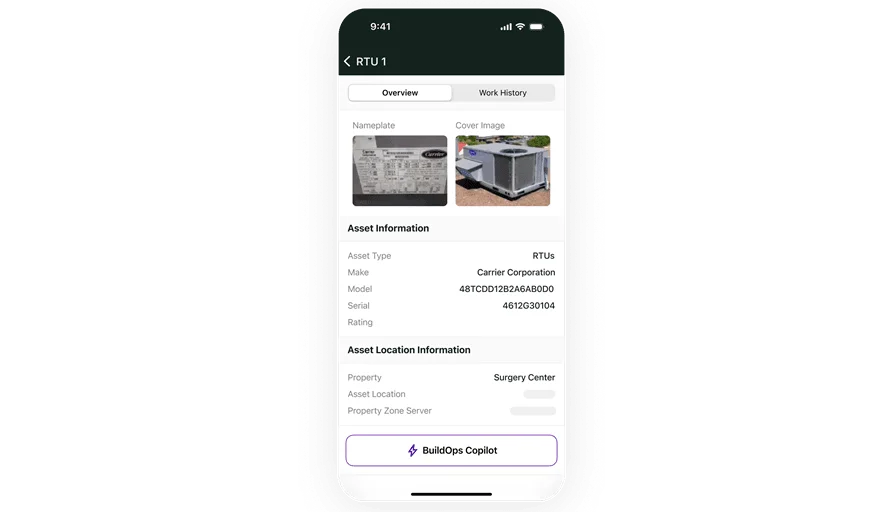

5. Centralize asset records and make them accessible

Store everything—warranties, service logs, inspections, user assignments—in a single system your team can actually access. This shouldn’t live on a desktop in the office. It should be live and viewable in the field, especially during service calls or inspections.

6. Train field and office teams on using the system

Don’t dump software on your crews and expect them to figure it out. Walk them through how to scan assets, assign gear, log maintenance, and use the database. Tailor the training by role—dispatch needs to see availability; techs need quick access to asset history. Everyone should know how this supports their day-to-day work.

7. Connect assets to job scheduling and dispatch

Field asset management only works if it’s tied to your operations calendar. Your dispatchers should know what equipment is available and ready before scheduling a job. That means asset data has to live inside your scheduling tools—not in a separate tab. Learn how this integration works in action through this field service management solutions breakdown.

8. Make mobile functionality the standard

If your techs can’t access the system in the field, they won’t use it. Mobile asset management tools should allow offline access, quick scan-in/scan-out, and instant updates tied to job tickets. If managing your mobile crews is part of the challenge, this guide to field service mobile workforce management breaks down how top teams handle it.

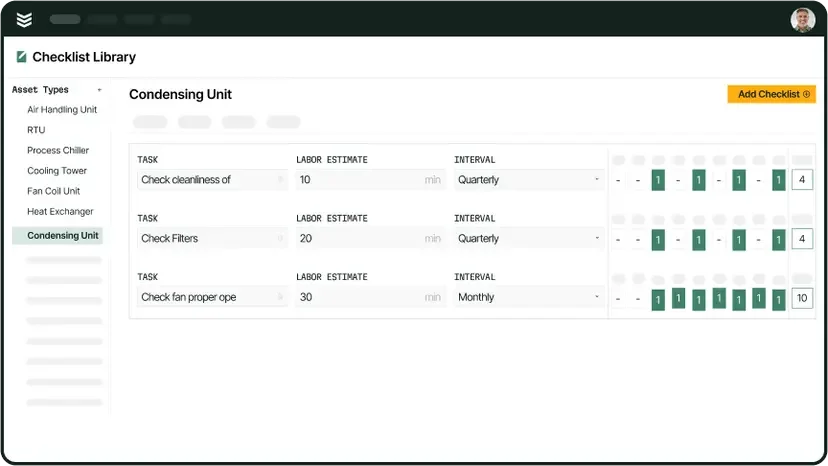

9. Automate reminders for maintenance, calibrations, and inspections

Set alerts based on time intervals, usage data, or service logs. If a tool needs calibration every 50 uses, your system should flag it. If a generator hasn’t been inspected in 90 days, get it on the schedule. These automations keep your fleet in compliance and reduce emergency fixes that could’ve been planned for.

10. Review performance and scale what works

Track how your asset system impacts operations: fewer lost tools, faster dispatching, fewer job delays. Once it’s working, don’t stop there. Expand the system to include more teams, new asset types, or additional locations. The key is making asset management a long-term part of your field service strategy—not a one-time setup.

8 field asset management best practices to enhance your operations

You’ve got a system in place, but making it work day in and day out takes more than just setup—it takes discipline and smart habits. These best practices keep your field asset management running strong, no matter how many crews or job sites you’re juggling. Think of these as your operations tune-up list—simple shifts that drive real results.

1. Tie assets directly to job planning

Assign assets during job scheduling, not after. This makes sure techs show up with the right gear—and no one’s scrambling last-minute. Build checklists for common job types so equipment gets prepped early. This field service planning guide shows how to set it up without adding complexity.

2. Build dashboards that show asset status in real time

Use live dashboards to track who has what, where it is, and when it’s due for service. You’ll catch bottlenecks before they turn into downtime. If your team’s still relying on manual updates or siloed systems, it’s time to upgrade with field service dashboards that give a full operational view.

3. Use automation to trigger maintenance

Don’t wait for something to break. Automate service schedules based on usage, job count, or time intervals. It keeps your gear reliable and extends asset life. Automation plays a key role in smarter systems—check out how it fits into AI in field service management.

4. Tag and track customer-owned assets

Your system shouldn’t just manage what you own—it should log the assets you’re servicing too. Tag HVAC units, generators, or control panels at customer sites so your team can pull up service history fast. This turns your field asset management into a customer service advantage. Field service CRM software can help you manage these relationships with precision.

5. Keep mobile tools front and center

If your techs can’t log asset updates on their phones, they won’t do it. Use a mobile-first platform that includes scan-in/scan-out, offline access, and field-ready dashboards. This ensures updates happen in real time. Explore field service optimization to see how mobile can transform your workflow.

6. Track utilization, not just location

Knowing where an asset is doesn’t mean it’s pulling its weight. Monitor how often each tool gets used and compare it to its cost. If high-ticket equipment is underutilized, it might be time to reassign, resell, or replace it. This type of insight is one of the most overlooked benefits of field service management.

7. Flag issues at job closeout

Add a simple checkpoint: Did all gear come back, and is it still working? Have techs confirm asset status before they fully close out a job. If anything’s damaged or missing, it gets logged right away. No more chasing info a week later.

8. Review asset data quarterly

Set time aside every quarter to review asset performance. Track trends like failure rates, repair costs, and usage gaps. This keeps your system dialed in—and gives you the insight to scale up or slim down without guessing.

With best practices like these in play, your asset management field services won’t just run—they’ll run lean, accurate, and fast. But having the right process only gets you so far. Let’s look at the tools that actually make it work in the field.

Top 3 field service asset management software for contractors

When it comes to managing assets in the field, not all software is created equal. You need a platform that tracks tools and equipment while also supporting the rest of your operation—dispatching, scheduling, reporting, and more. Here are three top picks depending on what kind of work you do.

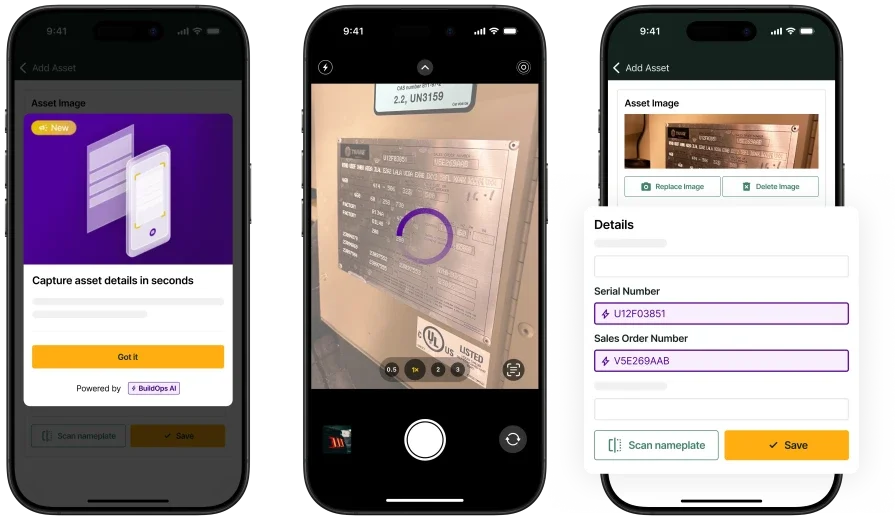

1. Best for commercial: BuildOps

BuildOps is designed specifically for commercial contractors, making it the strongest option for shops managing large equipment fleets, scheduled maintenance programs, and multi-asset job sites. It gives operations leaders full visibility into where assets are, how they’re being used, and what needs attention—all from a centralized platform.

How pricing works: BuildOps uses a customized pricing model based on the size and needs of your business. You’ll need to request a demo for tailored pricing.

Features beyond asset management: The platform brings dispatching, scheduling, invoicing, quoting, and reporting together into one system. Techs in the field can log asset use in real time, while office staff can track jobs, generate quotes, and manage service history—all without leaving the dashboard. It’s built to handle the scale and complexity of commercial work, and that means fewer bolt-on tools to manage.

What sets it apart for commercial: BuildOps is purpose-built for commercial field service. It handles customer hierarchies, complex job workflows, and recurring service calls—all while keeping assets organized and visible in the background.

Asset info at your fingertips

Equip field techs with instant asset capture tools to collect & access the info they need.

2. Best for residential: Housecall Pro

Image Source: Housecall Pro

Housecall Pro is a solid choice for smaller residential service teams who want easy job booking and simple asset logging. It includes core features like customer management, scheduling, and payment collection with a user-friendly interface that’s great for lean operations. However, it lacks some of the advanced asset tracking and enterprise-level customization needed for large commercial teams.

How pricing works: Pricing starts around $59/month for basic features, with asset tracking available on higher-tier plans.

Features beyond asset management: You get invoicing, automated reminders, GPS tracking, and mobile payment features, making it an all-around tool for residential service companies. It’s also known for its customer communication features, including text updates and review requests.

What sets it apart for residential: Its strength lies in simplicity and usability, especially for teams that don’t need complex workflows or asset categorization by client, site, or job type.

Check out our side-by-side comparison of Housecall Pro and BuildOps features to see which one meets your field asset management needs better.

3. Best for specialization: Jobber

Image Source: Jobber

Jobber stands out for specialized contractors—lawn care, cleaning, pest control—who want light asset tracking combined with strong client communication and job tracking tools. It’s clean, easy to use, and works well for teams with tight service routes. But it may fall short if your work includes a wide range of high-value field assets or requires deep integration with dispatching systems.

How pricing works: Jobber’s pricing starts at $25/month for basic use for one user, with mid-tier plans including job tracking and limited asset functionality.

Features beyond asset management: It offers online booking, real-time job updates, quoting, and a customer portal for service tracking. Asset management is more of an add-on here, suitable for lighter field use rather than asset-intensive work like HVAC or plumbing.

What sets it apart for specialization: Its flexibility makes it a go-to for niche industries where full-scale asset tracking isn’t necessary, but scheduling and client touchpoints are.

Field service asset management isn’t just a backend system—it’s the engine that keeps jobs moving, techs equipped, and operations accountable. Whether you're running HVAC, plumbing, electrical, or mechanical service teams, tracking assets in the field is what turns last-minute chaos into predictable, productive workdays.

But here’s the catch: most software tools stop at the basics. You’ll find platforms that handle scheduling. Others that track parts. A few that log maintenance. Rarely do you get all of it working together—especially at the scale commercial contractors need. That’s where platforms like BuildOps make a difference. It’s one of the few systems that ties asset management directly into your dispatch, quoting, and customer workflows—without duct-taping different tools together.

Curious to see BuildOps in action?

See how asset management works when it’s built into a single, connected platform.