Managing mechanical projects takes grit. You’ve got crews juggling ductwork, piping, pressure testing, system installs—often all at once and across multiple sites. And when the pressure's on, small delays can throw your whole schedule sideways. Mechanical contractor project management software keeps things from slipping through the cracks. It connects your team, centralizes your data, and puts everything from submittals to change orders at your fingertips.

Whether you're coordinating HVAC systems on a high-rise or managing plumbing installs across retail chains, this kind of platform keeps your jobs tight and your team sharper. If you're in the middle of evaluating tools, field service management should be part of the conversation. It’s where job oversight meets technician coordination—and where solid project outcomes begin. We’ll cover everything, including:

- Choosing the right mechanical contractor project management software

- 6 key features to get in a mechanical contractor project management software

- Best MCPM software for commercial contractors

- Best for residential contractors

- Best for general contractors

- Other mechanical project management tools worth checking out

- 7 benefits of using project management software for mechanical contractors

- 4 important FAQs about mechanical contractor project management software answered

Before we dive in, it’s worth taking a step back. Not every mechanical contractor project management software tackles the same problems—or solves them the way you need. Let's break down where to start when picking a solution that fits how your team works.

Choosing the right mechanical contractor project management software

Mechanical contractors rely on precision—whether it’s coordinating HVAC installs, managing piping layouts, or keeping pressure testing on track. The project management software you choose should match that same level of control. It’s not about piling on features—it’s about solving the actual bottlenecks that slow your jobs down. Here’s where to start:

- Workload and job scope – Are you managing short-turn service tickets or multi-month installs across multi-trade environments? Do you need a system that flexes between light commercial maintenance and full-scale new builds? How often do you find your team splitting resources across overlapping job phases?

- Field and office coordination – Can your foremen log updates directly from the field? Are change orders, pressure test results, and job photos being shared automatically with the back office? How often is your team chasing down info that should’ve been logged in real time?

- Scheduling and labor logistics – Are your techs showing up with the right gear and certifications for the job? Can you see truck locations, crew availability, and job timelines in one view? How much time is wasted reassigning jobs manually when schedules shift?

- Billing and cost tracking – Are time-and-materials jobs being tracked accurately? Can your billing team pull invoices with backup the moment a job wraps? Are change orders and PO logs centralized, or scattered across spreadsheets?

- Features – Does the platform support RFIs, submittals, pressure test logs, and daily field reports natively? Can your team actually use it without constant workarounds? Will it integrate cleanly with your estimating or accounting tools?

Next, let’s break down the essential features that actually make a difference—and how they show up in top mechanical contractor project management software platforms.

6 key features to get in a mechanical contractor project management software

Coordinating mechanical jobs across sites and systems takes more than whiteboards and guesswork. From duct runs and pump installs to last-minute change orders, the tools you use matter. Mechanical contractor project management software should keep every moving piece in sync—office to field, bid to closeout.

1. Scheduling and dispatching

Project delays cost money. Whether it's rigging a rooftop unit or staging a hydronic system, the right field service scheduling and dispatch software helps mechanical contractors coordinate labor, trucks, and tasks in real time. Say a pipefitting crew finishes early—dispatch can instantly reroute them to a nearby job with open tasks, no need for calls or clipboard juggling.

2. Technician mobile access

Techs in the field need instant access—not printed work orders. A reliable technician mobile app lets them log updates, upload photos, and flag issues directly from the jobsite. Picture a journeyman spotting a wrong valve spec during install—he tags it in the app, drops a photo, and the PM gets notified before it stalls the timeline.

3. Quoting and estimating

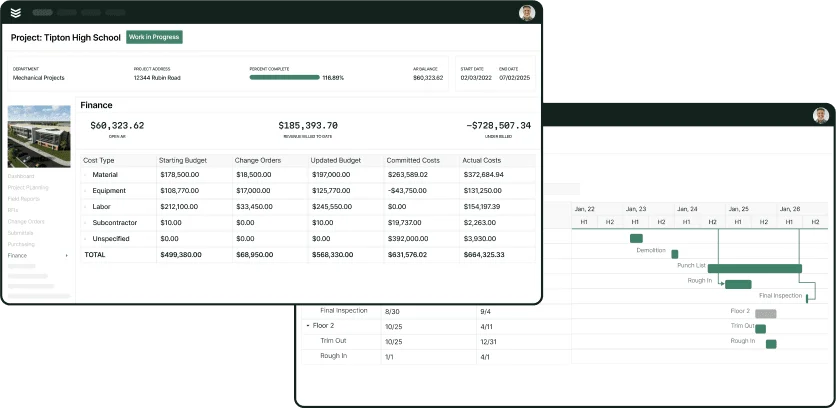

Accurate estimates keep mechanical contractors competitive. With field service quoting software, you can track labor, materials, and scope changes from quote to final invoice. If an engineer updates specs mid-bid on a high school HVAC job, your estimator can revise the numbers, sync them to the job file, and stay on deadline.

4. Invoicing and payment tools

T&M work adds up fast. Mechanical contractor project management software should pull time logs and materials directly into field service invoicing and support digital payment processing. Say your team wraps a chilled water line replacement—your office can bill it that day, with all backup attached, and the GC can pay online without delays.

5. CRM and service tracking

Most mechanical contractors manage multiple properties and repeat clients. A dependable CRM system gives you job history, asset specs, and contact info at your fingertips. When a hospital facility manager calls about a hot water pump from a past install, your team can access test logs and prior work instantly—no wasted time.

6. Reporting and insights

Margins can disappear fast. With real-time reporting and analytics, you can track labor hours, change orders, and budget overruns before they snowball. After finishing a multifloor tenant improvement, for instance, you can see exactly which crews stayed productive and which tasks pushed timelines—and adjust the next job accordingly.

Explore our project management suite

We help mechanical crews manage projects seamlessly from the first call.

Other valuable features to look for in a mechanical contractor project management software

Once the fundamentals are covered—scheduling, dispatch, estimating, mobile access, invoicing, and reporting—it’s worth paying attention to the features that round things out. These aren’t always deal breakers, but they do have a real impact on how mechanical contractors manage jobs efficiently from the office to the field.

- Fleet tracking: With fleet management tools, mechanical contractors can monitor truck availability, fuel levels, and maintenance status all in one view. This is critical for teams coordinating heavy equipment or specialty tool transport. Keeping your vehicles running smoothly helps avoid costly downtime, missed lifts, or delayed start times due to breakdowns.

- Service agreements: For contractors handling recurring maintenance work—whether it's backflow testing, chiller inspections, or boiler tune-ups—service agreement tools help manage contract renewals, service schedules, and compliance timelines. These tools automate reminders, track scope terms, and ensure nothing falls through the cracks when juggling dozens of service customers.

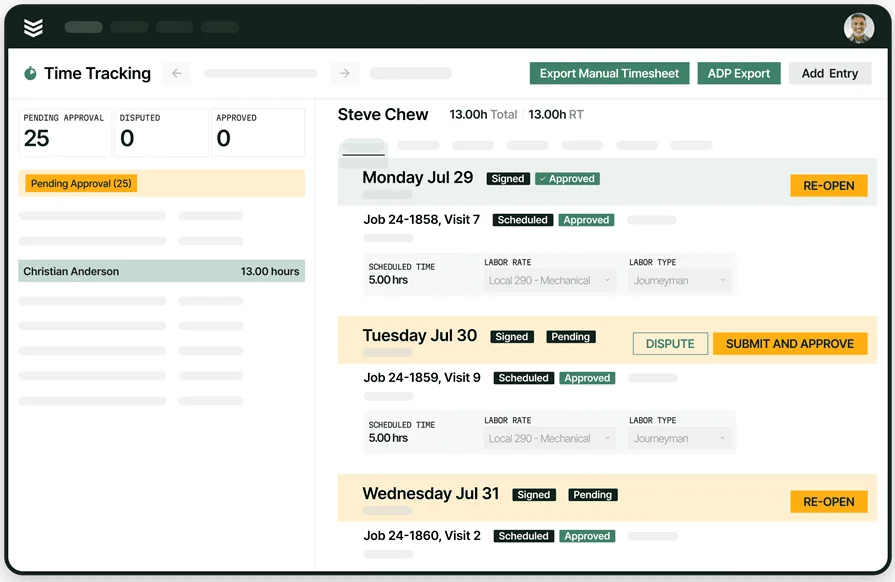

- Time tracking: Time tracking software is key for staying on top of labor costs, crew productivity, and accurate billing. Instead of relying on handwritten timecards, mechanical contractors can log hours directly from the field, split time between tasks, and generate labor reports in real time—critical for T&M jobs or tight-margin installs.

Now that we've covered both the essentials and the value-add features, you can start to see how a solid mechanical contractor project management software isn’t just a tool—it’s a central system for how your team runs jobs. From tracking crews and coordinating lifts to managing service contracts and labor hours, each feature plays a role in keeping your projects efficient, profitable, and on schedule.

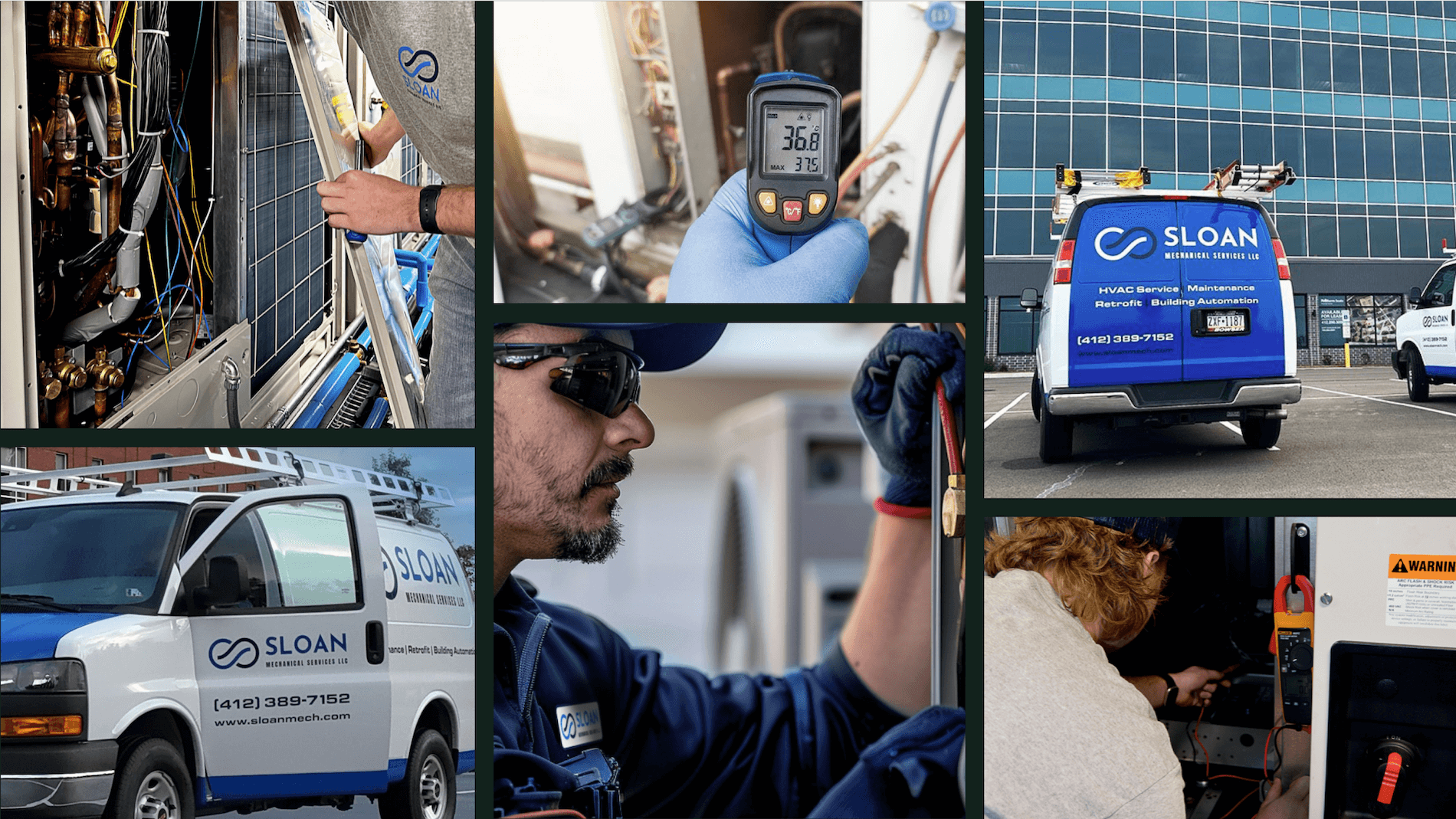

Best MCPM software for commercial contractors: BuildOps

BuildOps delivers what commercial mechanical contractors actually need—control, clarity, and real-time coordination across complex job sites. From multi-phase HVAC installs to tenant improvement retrofits, it brings every part of the operation into one connected system: estimating, scheduling, dispatching, field updates, job costing, billing—it’s all managed under one roof. No more hopping between platforms, chasing down updates, or second-guessing timelines.

How pricing works: BuildOps offers customized pricing based on your team size, scope of work, and feature needs.

Features beyond project management: BuildOps goes deeper than task tracking. It gives your teams mobile access for daily reporting, job costing tools tied directly to field activity, asset history for repeat service clients, and live visibility across all open jobs. It even tracks service contracts and compliance workflows—so you’re not scrambling during inspections or audits.

What sets it apart for commercial work: Most tools try to be one-size-fits-all. BuildOps was shaped around the daily grind of commercial mechanical work. It handles long timelines, constant scope shifts, change orders, and crew coordination without breaking down. Whether you're overseeing VAV replacements across a campus or chasing closeout docs on a large TI project, you’ve got full visibility from kickoff to final invoice.

See BuildOps in action

Keep mechanical crews in the field and office fully aligned on all projects.

Best for residential contractors: ServiceTitan

Image Source: ServiceTitan

ServiceTitan is widely adopted among residential mechanical contractors, especially those managing high volumes of service calls, routine maintenance, and customer-centric work. This software provides call booking, dispatching, payments, marketing, and basic project tracking for streamlining residential service workflows. Its project tracking features include scheduling, progress monitoring, and basic job costing for smaller installations.

However, contractors working on multi-phase installs or juggling several crews may find its project management capabilities limited compared to platforms tailored for larger or more complex jobs.

How pricing works: ServiceTitan operates on quote-based pricing, with costs scaling based on features and user count. Many of its more advanced functions are locked behind higher-tier plans.

Features beyond project management: The platform includes customer communication tools, technician sales tracking, and integrations with marketing platforms and QuickBooks. These are ideal for growing residential shops that prioritize responsiveness and lead conversion.

What sets it apart for residential work: ServiceTitan excels in helping contractors manage repeat business, homeowner relationships, and day-to-day scheduling. It’s a strong fit for residential-focused teams that need speed, automation, and CRM support more than deep project controls.

Considering ServiceTitan?

Deep Dive

We compare ServiceTitan and BuildOps side by side in this breakdown of their features, so you can measure their project management features more directly to see which one is the better fit for the type of mechanical work your team does.

Best for general contractors: Procore

Image Source: Procore

Procore is a well-known name in construction management and serves general contractors and subcontractors handling complex, multi-trade builds. It offers extensive tools for document management, RFIs, submittals, change orders, budgeting, and field collaboration.

For mechanical contractors working under GCs or running full-scale mechanical scopes, Procore’s centralized dashboard and detailed controls offer transparency across multiple stakeholders. Its mechanical contractor platform helps teams manage coordination, compliance, and job documentation across the full construction lifecycle.

That said, for mechanical contractors who primarily self-perform or focus on service and install work, Procore may be too heavy. Its size, setup time, and complexity can be a challenge—especially for teams that need speed in the field.

How pricing works: Procore uses custom pricing, typically based on annual construction volume and feature access. It’s geared toward companies managing multiple projects with several trade partners.

Features beyond project management: Procore includes detailed financial tools, quality and safety tracking, BIM integration, and submittal workflows. It supports deep collaboration between trades and GCs on large-scale jobs.

What sets it apart for general contractor work: Its strength lies in multi-trade coordination. Procore is built to manage documentation, communication, and cost controls across many teams and timelines—ideal for mechanical contractors working as part of broader construction teams.

Other mechanical project management tools worth checking out

Not every mechanical contractor needs an all-in-one system. If your team is focused on specific workflows—like estimating, time tracking, or document management—a more targeted platform might be a better fit. Below are five mechanical contractor project management software options that offer unique strengths, along with a few tradeoffs to keep in mind.

STACK

Image Source: STACK

STACK offers cloud-based preconstruction software tailored to the needs of mechanical contractors, with strong features for takeoffs, estimating, and bid management. It’s designed to speed up the front-end of your projects by making it easier to quantify materials, build out proposals, and collaborate with team members in real time. However, STACK focuses heavily on preconstruction and doesn’t provide deeper project execution tools like scheduling, dispatch, or field reporting.

How pricing works: Subscription pricing based on users and feature tiers

Features beyond project management: Digital takeoffs, estimating templates, and bid tracking

Where it fits best: Mechanical contractors looking to streamline estimating workflows and preconstruction collaboration

Access Construction

Image Source: Access

Access Construction provides cloud-based project management and job costing tools with specific capabilities for mechanical contractors. It offers features like document control, contract tracking, and budgeting dashboards designed to improve transparency. However, as a UK-based platform entering the U.S. market, it may lack the local integrations and support some North American teams expect.

How pricing works: Tiered subscriptions based on user count and feature access

Features beyond project management: Subcontractor oversight, document storage, and performance monitoring

Where it fits best: Growing mechanical contractors who want structured back-office controls

Fieldwire

Image Source: Fieldwire

Fieldwire is a mobile-friendly coordination tool built for the field. Mechanical contractors use it to manage punch lists, jobsite tasks, and plan markups directly from the field. While great for on-the-ground updates and checklists, Fieldwire doesn’t include advanced financial tracking or service workflows, making it less ideal for larger project-based operations.

How pricing works: Free plan available; paid tiers scale by features and user roles

Features beyond project management: Drawing management, inspection workflows, and task coordination

Where it fits best: Smaller subcontracting teams that prioritize field communication

Jonas Software

Image Source: Jonas

Jonas is a fully integrated solution designed for mechanical contractors who want accounting, project management, and dispatch in one system. It emphasizes connecting financial and job data from the office to the field, improving visibility across operations. That said, its interface and user experience may feel dated compared to newer, mobile-first platforms.

How pricing works: Custom pricing based on user count and selected features

Features beyond project management: Payroll, work orders, accounting, and inventory

Where it fits best: Mid-size contractors looking for back-office and field integration

Raken

Image Source: Raken

Raken simplifies daily reporting, field documentation, and time tracking for mechanical contractors. Its strength lies in making it easy for foremen and superintendents to submit updates without paperwork. However, it lacks deeper project controls, financial tracking, or service management features, which may limit its use for contractors running more complex operations.

How pricing works: Per-user pricing with optional add-ons for timecards and reports

Features beyond project management: Safety reports, daily logs, time tracking, and photo documentation

Where it fits best: Mechanical crews that need quick, field-level reporting—not full-scale project tools

Get the Mechanical Contractor Playbook

This guide helps mechanical contractors streamline processes and boost efficiency.

7 benefits of using project management software for mechanical contractors

Project deadlines, shifting specs, and crew coordination—mechanical contractors have to manage it all without missing a beat. Project management software gives you the control and clarity to do that job better, every day. Here are seven real benefits mechanical teams get when they rely on the right tools.

1. Fewer scheduling gaps

With multiple installs and service jobs running at once, it’s easy to miss overlaps or create downtime between tasks. Project management software gives you a live view of schedules across teams and job sites—helping you spot conflicts before they become problems. As highlighted in many field service planning practices, it’s the key to keeping labor efficient and equipment moving without costly delays.

2. Faster field-to-office updates

When RFIs or changes come up on-site, the office needs to know immediately—not hours later. Good software syncs field notes, photos, and updates in real time so dispatch and project managers can adjust without slowing down the job. It’s a major upgrade to how most teams handle dispatch and job flow in mechanical contracting, where lagging communication often leads to costly missteps.

3. Better visibility across all active jobs

Managing multiple crews without constant phone calls? That’s where project dashboards shine. Job status, pending inspections, next steps—it’s all in one place. You don’t just know where things stand; you know what’s next and who’s responsible.

4. More accurate job costing

Labor hours, material use, and equipment logs that flow straight into the job file help you get a clear read on project profitability. Mechanical contractors can use this to quote smarter, reduce padding, and avoid margin surprises when the job wraps. It’s a critical move for crews working fast-paced installs with frequent scope shifts.

5. Tighter customer relationships

When a technician walks into a job knowing the site history, equipment specs, and past issues, service feels seamless. Project management software that integrates with CRM tools designed for field service helps contractors track all those client-specific details—making repeat visits smoother and more professional.

6. Smoother closeouts

Getting to final inspection without scrambling for punch list updates or missing documentation takes coordination. When everything from job logs to billing is already synced in the system, closeouts happen faster. You’re not waiting on paperwork—you’re sending it.

7. Stronger jobsite control

The biggest win? Control over how your jobs unfold. Mechanical contractor project management software ties every moving piece together—labor, tasks, equipment, cost tracking—so your crew isn’t reacting to problems, they’re staying ahead of them. And when those systems reflect best practices in contractor project management, the entire operation runs tighter.

4 important FAQs about mechanical contractor project management software answered

There’s no shortage of platforms claiming to help you manage your mechanical jobs. But when you’re already neck-deep in installs, RFIs, and material tracking, you don’t have hours to sift through the noise. Whether you’re trying project management software for the first time or reevaluating your current setup, these questions get to the heart of what mechanical contractors actually need from their tools.

1. What is mechanical contractor project management software?

Mechanical contractor project management software help teams manage job scheduling, crew coordination, field documentation, and cost tracking. It supports the entire operation—from kickoff to closeout—whether you’re handling a new unit install or coordinating a pipe reroute under a tight deadline.

More than a task board, it’s tailored to field-heavy, equipment-critical work that includes daily logs, dispatch, submittals, and budget tracking. It links your field teams, PMs, and back office so everyone sees the same real-time info—like labor hours, jobsite issues, or pending approvals—keeping your projects moving and your margins tighter.

2. How does project management software for mechanical contractors work?

Project management software gives mechanical contractors one platform to organize every moving part of a job. Whether it’s daily work orders or large-scale commercial installs, it connects your techs, office, and clients—so no one is stuck working off outdated information. Here’s how it typically works on mechanical jobs:

- Assign crews based on certifications, equipment handling, or trade specialization

- Dispatch field techs with full access to drawings, specs, and site instructions

- Track labor, materials, and equipment hours without relying on paper logs

- Capture inspections, RFIs, change orders, and service notes right from the field

- Sync updates with the office for billing, payroll, and scheduling

- Store job-specific data like asset tags, site conditions, and maintenance logs

Everything feeds back into the same system, so mechanical jobs run smoother—with less time wasted chasing down updates or fixing communication gaps.

3. Is project management software worth the cost for mechanical contractors?

For mechanical contractors juggling fast-moving installs, multiple crews, or overlapping service contracts—the answer’s yes. The right software reduces the friction between field and office, cuts back on rework, and helps your teams stay productive. Instead of spending hours fixing miscommunication, you get that time back.

Whether you're coordinating a boiler install or juggling change orders during a chilled water retrofit, the whole process gets documented—labor, materials, and updates. That kind of visibility means faster billing, fewer mistakes, and better margins. And more often than not, the cost of the software is less than what you’d spend fixing preventable issues.

4. What are some best practices to follow when implementing project management software as a mechanical contractor?

Rolling out mechanical contractor project management software takes more than a login—it starts with a clear plan and field buy-in. Mechanical contractors need to align the platform with how their jobs actually run in the field. Whether you’re focused on install crews, pipefitters, or service techs, the system has to reflect your real workflows. Here are 10 best practices mechanical contractors should follow:

- Set jobsite-driven goals: Focus on real problems—missed approvals, delayed service calls, late inspections

- Involve your lead techs: They’ll flag the handoffs and gaps that slow your field teams down

- Use mechanical-focused platforms: Look for support for RFIs, submittals, and jobsite notes—not just task lists

- Create repeatable workflows: Build templates for shutdowns, system installs, and maintenance contracts

- Train crews on mobile tools: Make sure techs know how to log notes, photos, and job time from the field

- Roll out in phases: Start with a service team or specific division before going all-in

- Link estimating with billing: Let your quoting, labor logs, and invoicing stay connected

- Monitor usage: Make sure both field and office are actually using the system, not just one side

- Collect crew feedback: Regular check-ins help you improve workflows and catch early issues

- Adapt over time: As your work scales or shifts, tweak processes to keep jobs running right

When you build your process around how your mechanical teams operate—not just how the software is designed—you’ll actually see a return that sticks.

Mechanical contractor project management software isn’t just about staying organized—it’s about staying ahead. Whether you're overseeing a hospital HVAC install, coordinating teams on multi-phase tenant improvements, or balancing service contracts across multiple sites, the tools you use directly impact your bottom line. The right platform brings your crew, your office, and your job data together—so work flows, nothing gets missed, and your operation runs tighter from start to finish.

Every feature matters when the jobsite is moving fast. From scheduling and dispatch to field reporting and cost tracking, mechanical contractors need a system that mirrors the way real work gets done. And if you're working in the commercial space, a platform like BuildOps can help keep every piece connected—project and service work, all in one place.

Curious how BuildOps can help?

See how we help mechanical teams streamline operations and increase profits.