Managing your tools and materials might not be the loudest part of the job—but when it’s out of whack, it slows everything down. Plumbing inventory management keeps your trucks stocked, your warehouse organized, and your crew ready to tackle any job that hits the board. Whether you’re running a one-van operation or coordinating dozens of techs across job sites, this guide breaks down how to bring clarity to the chaos.

You’ll get real strategies for tracking your parts, planning reorders, and avoiding the late-night supply runs that kill productivity. We’ll also walk through inventory lists, best practices, and software options that actually work in the field—not just on paper. If you're working in the plumbing industry, this guide is built to help you stay ready and ahead of schedule. Here’s what we’ll cover:

- What is plumbing inventory management?

- Plumbing inventory list management: how to keep track effectively

- 7 benefits of having an integrated plumbing inventory management system

- 10 plumbing inventory management best practices you should follow

- Best plumbing inventory management solutions & tools

Before we dive into tools, templates, or tactics, let’s start with the basics. What does plumbing inventory management actually mean—and why does it matter so much for contractors?

What is plumbing inventory management?

Plumbing inventory management is the hands-on system of organizing, tracking, and restocking the pipes, fittings, tools, and gear that keep your team ready for every job. It’s what makes sure parts are where they should be, in the shop, or at the job site—so you’re not losing time or money chasing missing materials.

Done right, it keeps crews moving, cuts down on waste, and helps avoid last-minute scrambles that throw schedules off track. At the heart of it, plumbing inventory management is about flow—moving materials smoothly from your supplier to your shelves to your service calls. Whether you're managing gear for repipes, emergencies, or commercial builds, a strong inventory setup means your team has what they need, when they need it. No more losing time digging through bins or making extra supply runs. It's about keeping jobs tight, crews focused, and customers happy.

How does inventory management for plumbing contractors work?

Plumbing inventory management connects the dots between your materials and the work getting done out in the field. It keeps jobs moving without the chaos of last-minute part hunts, missing valves, or wrong-size fittings. Here's what that looks like in a plumbing shop:

- Ordering and receiving supplies: Gear up based on upcoming jobs and service demands. Every valve, elbow, or water heater that comes in gets logged into a system—whether that's software, spreadsheets, or a digital tracker.

- Organizing stock: Materials are sorted and stored by type, size, and use—whether on warehouse racks, service vans, or jobsite trailers. Your crew should know exactly where to grab what they need without wasting a minute.

- Tracking usage: Every pipe fitting, PEX coil, or flange pulled from the shelves gets tracked. Whether it's barcode scans or simple mobile apps, tracking what's used helps you spot trends and catch shortages early.

- Reordering parts: When inventory dips below a set point, your system flags it for restock. Smart setups prevent dry runs to the supply house when you realize you’re out of critical fittings halfway through a job.

- Job costing and reporting: Materials get linked to each project or work order. That way you know exactly where your parts (and money) are going—and you tighten up future estimates by knowing what a job really uses.

In short: it's a cycle. Receive, store, track, replenish. Miss a step, and your jobs slow down—and so does your cash flow.

Why plumbing inventory management systems matter to contractors

Trying to manage plumbing inventory by hand is a fast track to mistakes. Parts go missing, crews show up missing crucial fittings, and jobs crawl to a halt while someone scrambles to the supply house. A strong system stops the mess before it starts. Here’s what a well-run plumbing inventory setup delivers:

- Live stock visibility: Know exactly what’s on each van, in the shop, or at a job site—without picking up the phone or digging through shelves.

- Quicker restocks: Set triggers so you know when you're running low on essentials like couplings or PEX rolls—no guesswork needed.

- Cleaner pull tracking: Barcode scans, mobile apps, or connected lists mean fewer mix-ups, missing parts, or double ordering.

- Tighter job costing: Every valve, fitting, and tool gets tied to the job that used it—making billing sharper and highlighting hidden leaks in your profits.

- Less wasted admin time: Crews and office staff spend less time chasing inventory and more time getting real work done.

And when you’re juggling multiple trucks, hundreds of parts, and overlapping service calls, a sloppy system costs you more than just time—it drains your cash and your crews’ momentum. Plumbing inventory management isn’t a “nice to have”—it’s how you keep your operation locked in and moving forward.

Plumbing inventory list management: how to keep track effectively

If your inventory list is a mess, your jobs will be too. A solid list keeps you from double-ordering supplies, scrambling for missing parts, or slowing down mid-job. It also ties directly into billing—making it easier to charge for every fitting, pipe, and fixture you use. Using a plumbing invoice template helps connect your material tracking with your invoicing, so nothing gets missed when it’s time to bill the customer.

Let’s break down what an effective plumbing inventory list should cover—and why it matters.

What information should be included in a plumbing inventory list?

Here’s what you’ll want to track for every part and material:

- Item number (SKU): A unique identifier so similar parts don’t get mixed up—especially fittings, valves, and pipe sizes.

- Product name: Use the same names you’ll find on supplier invoices. Consistency saves time when reordering or billing.

- Description: Quick details that separate similar parts, like “1/2-inch PEX tee, brass.”

- Quantity on hand: The exact number you’ve got across trucks, warehouse shelves, or trailers.

- Reorder threshold: A set number where stock gets flagged for restock before it hits zero.

- Storage location: Where the part is physically—warehouse aisle, service van bin, jobsite box.

- Vendor info: Who you buy it from, including any contract pricing or preferred suppliers.

- Unit cost: What you paid per piece—critical for real job costing and profit margins.

- Last restocked date: So you know what’s moving and what’s just collecting dust.

Essential plumbing materials to track

These are the materials no plumbing inventory list should ignore:

- Fittings: Tees, elbows, couplings—small but essential, and easy to burn through fast.

- Pipes: Copper, PEX, PVC, CPVC—different jobs, different needs. Know what’s stocked and where.

- Valves: Ball valves, gate valves, check valves—critical for everything from repairs to full installs.

- Water heaters: Tank and tankless units—high-dollar items you need full visibility on.

- Fixtures: Faucets, toilets, sinks, and shower assemblies—track by model and finish.

- Fasteners and hangers: Clamps, straps, anchors—low cost but high importance.

- Sealants and adhesives: Pipe dope, thread seal tape, PVC cement—essential supplies you don’t want to run out of mid-job.

- Specialty tools: Pipe cutters, press tools, threading machines—track these just like materials to cut down on loss.

- Safety gear: Gloves, goggles, knee pads—small costs that stack up fast if you’re not watching.

- Consumables: Flux, solder, sandpaper, and gaskets—cheap but critical for day-to-day jobs.

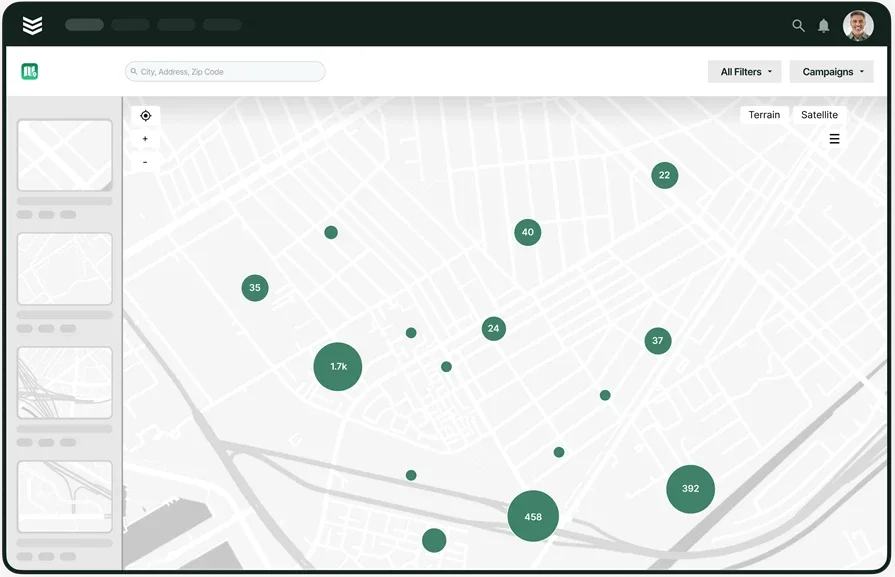

Explore BuildOps’ CRM

See how you can empower your team to track inventory and field techs.

Top 3 plumbing supply inventory list templates to base yours off of

When you’re managing inventory across vans, warehouses, and job sites, a solid template can give you a head start. These tools help track quantities, prices, reorder points, and vendor info—without building a system from scratch. Here are three strong options tailored for the plumbing trade:

- SmartSheet: This spreadsheet-based template includes columns for part numbers, descriptions, quantities, reorder levels, and storage locations. It’s user-friendly and easy to update. If you're already working in Excel or Google Sheets but need more structure, this gives you better control without needing new software. Bonus: It includes built-in flags for low stock.

- Coefficient: Coefficient turns your basic Google Sheet into a smart inventory system. It can pull in vendor data, auto-update quantities, and send alerts when stock hits reorder levels. It’s a good pick for plumbing teams who want more automation while staying inside the Google ecosystem.

- ProjectManager: This template is designed for managing both materials and job schedules. Great for teams that need to keep inventory and project progress in sync—especially when coordinating installs, inspections, or phased plumbing jobs. It includes task tracking alongside inventory fields, helping ensure the right materials are on-site when they’re needed.

Templates are a solid starting point—but they only go so far. If your list isn’t connected to job costing, scheduling, and invoicing, you’re still chasing parts and plugging leaks after they’ve already slowed you down.

7 benefits of having an integrated plumbing inventory management system

When your inventory works in isolation, you lose time, materials, and visibility. Connecting it to scheduling, invoicing, and your team’s day-to-day workflow turns it into a system that supports your entire operation. Here’s how an integrated plumbing inventory management system changes the game:

1. No more job delays

Missed fittings, empty bins, or untracked tools can stop a job cold. But when inventory syncs with dispatch, you’ll know if every part needed for tomorrow’s call is already on the van. The kind of coordination outlined in this plumbing field service software overview shows how tighter workflows between stock and scheduling keep jobs on track.

2. Better material planning

You’ll see what parts your team burns through fastest, which ones are rarely touched, and what needs restocking before it runs out. Over time, those patterns make ordering smarter and less reactive. For techs managing mobile stock across locations, the plumbing inventory app highlights how to track movement in real time and stay ahead of demand.

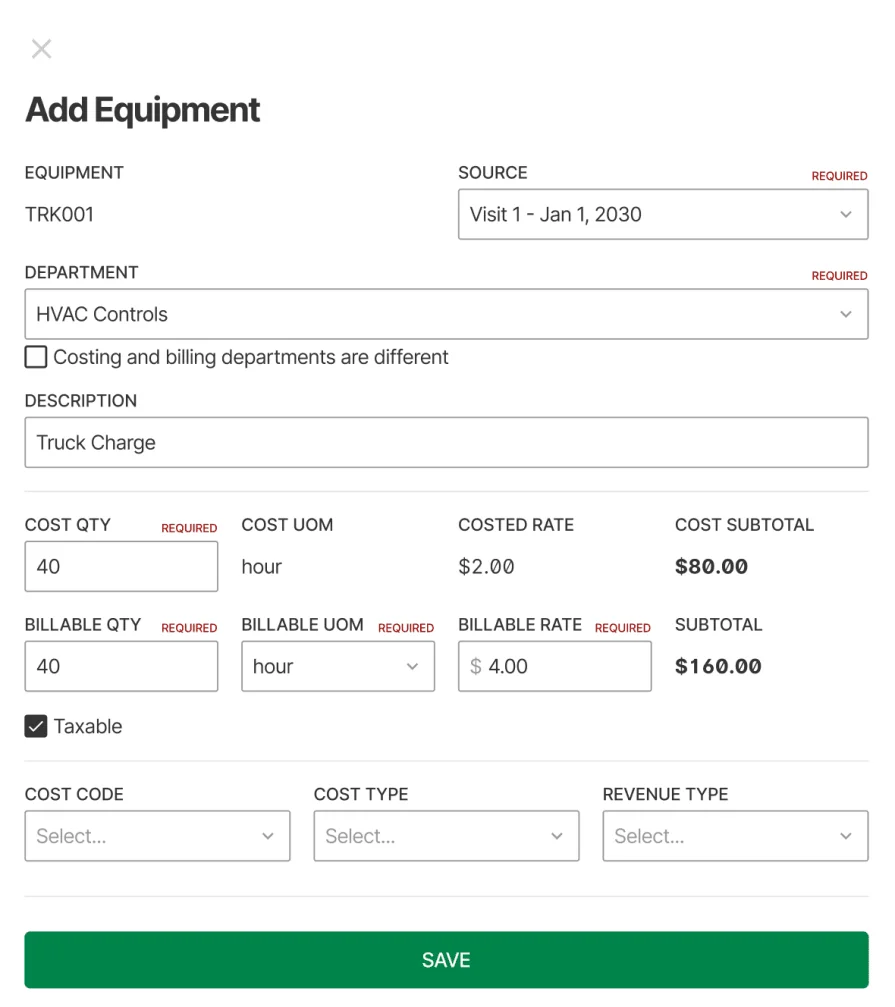

3. Accurate job costing

Linking material usage directly to each work order lets you see exactly what’s being spent—not just on labor, but on every tee, elbow, or drain assembly that goes into the job. With accurate records, your quotes improve, your margins tighten, and your invoices reflect reality. This is broken down clearly in the comprehensive guide to plumbing invoicing, which shows how synced inventory data improves billing accuracy.

4. Real-time visibility

Your team shouldn’t have to call the warehouse or guess what’s in stock. A live system lets them know what’s available across trucks, shelves, and storage units—before they even pick up a part. Visibility like this is essential when juggling multiple projects or scaling operations, as shown in this plumbing company growth data report, where leading contractors are optimizing every part of their material pipeline.

5. Streamlined reordering

When inventory levels drop, your system should let you know—or better yet, trigger the reorder automatically. No more missed fittings or delays waiting on overnight deliveries. This kind of automation keeps your high-use items available and your jobs moving without tying up cash in dead stock.

6. Cleaner handoffs between office and field

Everyone—from your dispatcher to your tech in the van—needs to be on the same page. Integrated systems eliminate the back-and-forth by giving both sides real-time updates on what’s been used, what’s left, and what needs restocking.

7. Insight into what's driving—or draining—profit

Inventory data gives you more than numbers. It shows you what your best techs are using, where you're overordering, and how to plan smarter for seasonal work or new build-outs. That insight shapes better decisions across the business—from quoting to vendor negotiations.

10 plumbing inventory management best practices you should follow

Running inventory across multiple trucks, job sites, and warehouses without a playbook leads to one thing: chaos. You end up overordering some parts, running out of others, and wasting hours chasing what should’ve been on hand in the first place. The contractors who stay ahead don’t wing it—they follow repeatable systems that keep their inventory lean, reliable, and job-ready.

Here are 10 field-tested best practices that will help you build a system your team can count on every day.

1. Set minimum stock levels for essentials

Start by identifying your most-used items—think copper fittings, valves, couplings, and Teflon tape. Then assign a minimum quantity to each one based on job volume and lead time. When stock falls below that level, you restock before it runs out. This simple tactic reduces job delays, keeps techs equipped, and avoids the higher costs of emergency restocking. Make this part of your standard process, not something left to memory or someone’s gut feeling.

2. Assign inventory by van or crew

Treat each truck like its own inventory hub. Load it with the materials needed for that crew’s usual jobs and track what goes in and out. Assigning stock by team or truck gives you visibility into who’s using what—and how often. It also helps you spot inconsistencies early. If one tech is blowing through PVC fittings faster than the rest, you'll know. Pair this with usage tracking software, and you’ll gain not just accountability, but real insight into field-level demand.

3. Use labels, bins, and standard naming

It’s one thing to stock parts. It’s another to make sure they’re easy to find—especially under time pressure. Clearly labeled bins, grouped by part type or job type, cut down on confusion and wasted time. Stick to naming conventions that match vendor invoices. That way, what the tech sees on the shelf matches what the office sees on the purchase order. Good organization isn’t just about order—it’s about speed, clarity, and fewer costly mistakes.

4. Schedule regular cycle counts

Don’t wait for your annual physical inventory to catch problems. Break it into weekly or monthly mini-counts, rotating through item types or storage locations. It’s quicker, easier to manage, and more likely to get done. You’ll catch errors, shrinkage, or overstocking before they become real issues. A structured counting system also builds trust in your inventory data—so your estimates, reorders, and job costing don’t fall apart from bad numbers.

5. Connect inventory to work orders

Every fitting pulled from the shelf or bin should be linked directly to the job that used it. This gives you real-time insight into how much each job is actually costing—not just in labor, but in materials. It also helps with tracking warranty issues, managing returns, and backing up invoices. A system like this works even better when it’s built into your field management platform, like those discussed in field service management software compatible with QuickBooks, which ties material tracking to job costing and billing on the back end.

6. Build standard kits for common jobs

If your crews regularly handle the same types of work—like faucet installs, water heater swaps, or drain cleanouts—create standardized kits. These include every part typically used for that job type, pre-packed and ready to go. It reduces setup time, ensures nothing’s missed, and cuts down on waste from pulling more than needed. It also helps train newer techs by giving them a checklist to work from, rather than hoping they remember every fitting or fastener.

7. Centralize vendor and pricing info

Every time someone has to dig through old emails to find a part number or pricing, you’re losing efficiency. Centralize vendor data in one place—SKUs, contacts, standard pricing, and past order history. Having this info ready means faster reorders, better comparisons across suppliers, and more leverage when negotiating. Syncing vendor and pricing data into your broader system makes purchasing faster, more consistent, and easier to reconcile on the accounting side.

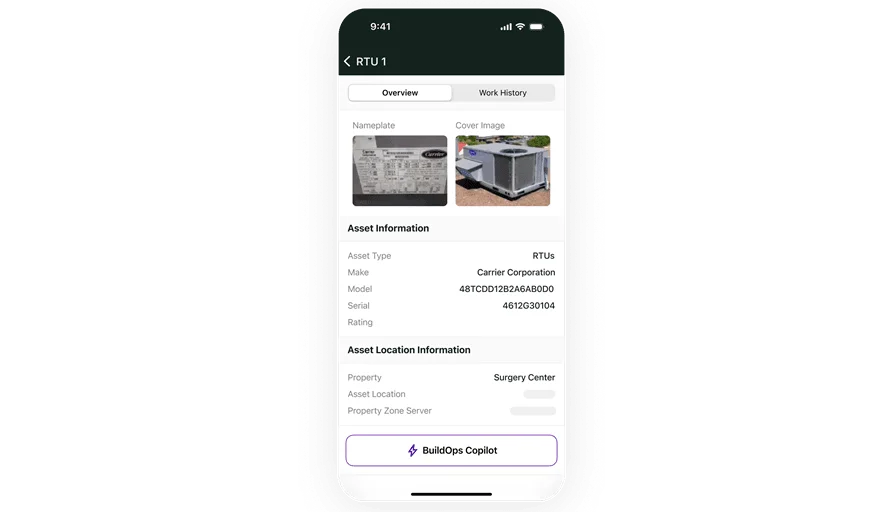

8. Track tools along with materials

Your fittings and parts may get billed to jobs, but what about your tools? Press tools, threading machines, leak detectors—these are expensive assets that tend to disappear unless you track them. Assign tools to trucks or techs and log them in and out like inventory. Not only does this reduce loss, but it also helps with tool maintenance and replacement planning. The more you track, the more control you have—and that includes your equipment, not just your parts.

9. Train your team to log usage in the field

Your system is only as good as the info going into it. Make logging part of your techs' daily routine. That means checking parts in and out of the van, flagging low stock, and updating the system after every job. When techs don’t log usage, your inventory data goes stale—and that’s how missed parts and lost revenue happen. As outlined in the benefits of field service management, syncing field activity with backend systems is what turns good processes into great ones.

10. Use software built for the way you work

Pen and paper might cut it when you’re just getting started—but once you’ve got a few vans, multiple techs, and service calls stacked back to back, you need something that scales. The best field service management software for small business breaks down how smaller shops can run with the same precision as larger teams by using platforms built around service workflows. That includes inventory tied to scheduling, dispatch, invoicing, and reporting—everything in one place, working together.

Now that you’ve seen how integrated plumbing inventory systems drive real results, it’s time to focus on the habits that make those systems work every day. Whether you're managing stock from the warehouse, the back of a van, or both, these best practices will keep your materials moving, your costs tight, and your jobs on schedule.

Streamline your invoicing process

Optimize invoicing so you don’t just get paid on time—you’ll get paid faster.

Best plumbing inventory management solutions & tools

If you're still relying on spreadsheets, whiteboards, or memory to manage your plumbing inventory, you're already behind. Stocking parts is one thing—keeping them organized across trucks, job sites, and warehouses is something else entirely. A dedicated system does more than track what you have—it connects your inventory to your jobs, schedules, purchase orders, and team in the field.

Tools like the plumbing inventory app show how much smoother things run when inventory isn’t just logged—it’s part of your operation. But not every platform is built for plumbing contractors or the way they actually work. Some are generic, some are overkill, and some don’t scale. Before jumping into specific software picks, it helps to know which features really move the needle. Let’s walk through what you should expect—and the ones that make the biggest difference on the job.

6 features to look for in a plumbing inventory management tool

Inventory management is about making that information useful across your entire workflow. From the warehouse to the van to the job site, the best tools make inventory part of how you schedule, quote, bill, and operate. These features are what actually matter for plumbing shops trying to stay efficient and job-ready.

- Live inventory tracking across every location: Whether it’s sitting on a warehouse shelf or tucked into Van 4’s storage bin, you need to know exactly what’s available. The best platforms show real-time inventory across all trucks and sites so your techs don’t waste time hunting or guessing. Visibility like this helps prep jobs faster and avoid surprise shortages.

- Material usage linked to jobs: Strong systems automatically tie every pulled part—valve, trap, pipe, or flange—to a specific work order. This tightens up billing, improves your estimating accuracy, and helps you spot which jobs are eating more material than expected.

- Mobile-friendly inventory access for field teams: Your techs shouldn’t need to call the office to figure out if a part is in stock. Mobile access lets them pull from the van, update inventory on the spot, and keep things moving. This makes inventory updates second nature instead of an extra chore.

- Reorder alerts and automation: When stock drops below a set level, smart systems flag it—or even trigger a PO automatically. That means you’re never caught empty on high-turnover items like fittings, solder, or shutoff valves.

- Integrated purchasing and vendor syncing: Good tools don’t just count parts—they help you manage the rest of the process. Built-in PO workflows and vendor data help you restock faster and cleaner, without searching through old invoices or juggling supplier calls.

- Usage reporting and cost tracking: The top platforms show what you’re using, how fast it’s moving, and where your costs are rising. You’ll know what’s burning through inventory, where waste is happening, and which materials need tighter control.

If you’ve got those features covered, you’re not just stocking parts—you’re managing your inventory like a system. Now the question is: which tools actually deliver that experience? Let’s break down the top plumbing inventory software picks and see how they stack up in real job conditions.

Top 3 plumbing inventory management software & tools

There are plenty of platforms out there promising to manage your inventory, but only a few actually deliver what plumbing contractors need in the field. Whether you're focused on commercial service, routine residential jobs, or a mix of trades, the right system should help you stay organized, job-ready, and profitable. Here's a breakdown of three solid picks—each with its own strengths and ideal use case.

1. Best for commercial plumbers: BuildOps

BuildOps was built with commercial plumbing contractors in mind. It handles the complexity of managing inventory across warehouses, job sites, and service trucks while tying into scheduling, quoting, dispatch, and job costing. Every material—from fittings and PEX coils to valves and fixtures—can be tracked as it moves through the job. Each part is tagged to a specific work order, user, and location, giving you full visibility without the paperwork.

What sets it apart for commercial: It’s the only platform purpose-built for commercial field service, with features like van-level stock control, real-time usage tracking, and inventory synced directly to job status. You get control from quote to closeout—without needing to piece together different systems.

Want to see BuildOps in action?

We connect inventory management to every part of the plumbing workflow.

2. Best for residential plumbers: Housecall Pro

Image Source: Housecall Pro

Housecall Pro is widely used by smaller plumbing businesses focused on residential service. It includes core tools for quoting, dispatch, invoicing, and basic part tracking. For shops doing quick turn jobs like fixture replacements or drain cleaning, it offers an easy setup and user-friendly interface. However, inventory tools aren’t deeply built into job costing or scheduling, and there’s limited visibility into stock across trucks or warehouses—making it less effective for growing operations or material-heavy work.

What sets it apart for residential: It’s lightweight and intuitive, making it a solid choice for small teams that don’t need complex inventory features or multi-location tracking.

See how Housecall Pro stacks up against BuildOps in our comparison of their features.

3. Best for simple plumbing inventory tracking: Sortly

Image Source: Sortly

Sortly is a visual inventory management tool that’s gained traction among plumbing contractors looking for a lightweight way to track parts, tools, and materials. It allows you to organize inventory with custom tags, photos, and barcodes—making it easier for teams to know what’s in stock without digging through spreadsheets. It’s especially useful for shops focused on small to mid-sized plumbing projects or maintenance work. While great for visibility and organization, Sortly doesn’t tie inventory into scheduling, dispatch, or job costing—so teams needing full-service field coordination may need to use other tools alongside it.

What sets it apart for simple tracking: Sortly’s visual interface makes it easy to train crews, log parts from the field, and manage items across multiple locations without requiring a complicated setup or integrations.

Strong plumbing inventory management is the backbone of a busy, profitable operation. It’s the difference between techs finishing jobs without delay—and jobs getting stalled over missing parts. Whether you're running a few service trucks or coordinating multi-site commercial installs, how you track, organize, and replenish your materials impacts everything from job costs to customer satisfaction.

The best systems don’t just keep parts on shelves—they connect inventory to your field teams, scheduling, invoicing, and reporting. If you’re managing a growing commercial plumbing business, using an all-in-one platform built for complex field service operations can help tie it all together without the manual headaches. Keeping stock moving, jobs flowing, and crews equipped becomes second nature, not a scramble.

Explore our inventory management tool

We help plumbing teams manage materials, field techs, and jobs from one place.