HVAC Вiagnostic Tools refer to instruments and devices used by technicians to measure, analyze, and troubleshoot heating, ventilation, and air conditioning systems. These tools play a crucial role in locating defects, verifying function, and ensuring systems operate efficiently. They encompass a wide range of equipment, including but not limited to, digital multimeters, clamp meters, refrigerant leak detectors, and infrared thermometers.

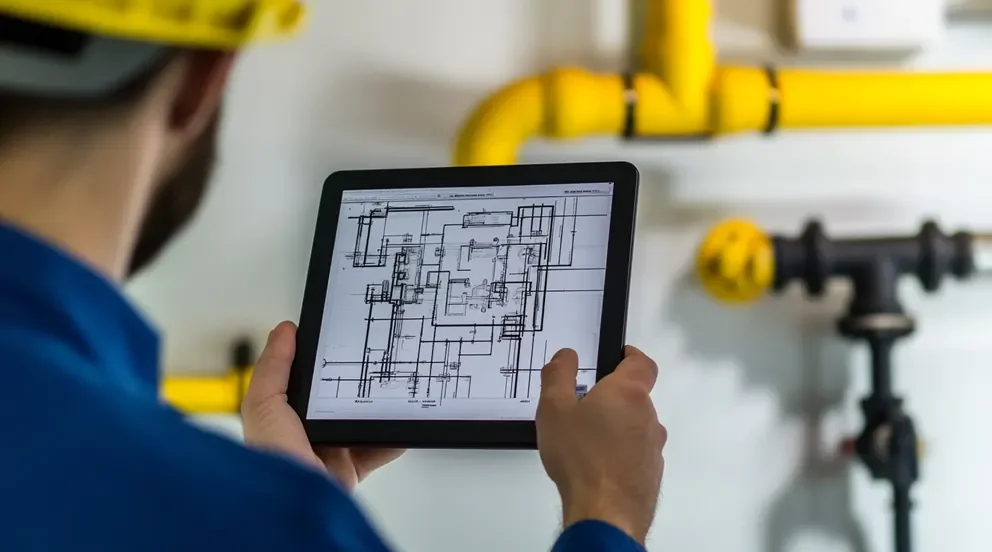

Skilled HVAC professionals depend on these diagnostic tools to maintain optimal system performance, reducing energy consumption and preventing costly breakdowns. Accuracy and reliability are key components of these instruments, as they must precisely detect inconsistencies and malfunctions. Some advanced tools have smart capabilities, connecting to mobile devices to convey real-time data and facilitating comprehensive system analysis for informed decision-making.

The evolution of HVAC diagnostic tools has paralleled advances in HVAC systems themselves. Modern devices integrate technology such as wireless communication, digital displays, and automated data collection. These enhancements not only improve the efficiency of diagnostic procedures but also make it easier to identify and resolve complex HVAC issues with unprecedented quickness and exactitude, elevating the standards of industry practice.

Content:

- Propelling HVAC Repairs into the Future with Innovative Diagnostic Tools

- Bridging the Repair Gap: How Advanced Tools are Reshaping HVAC Servicing

- The Emergence of Advanced Diagnostic Tools: A Boon for the HVAC Industry

- Redefining HVAC System Repairs: A Look at Technological Advancements

- Game-changing Diagnostic Tools: Boosting Efficiency in HVAC System Repairs

When it comes to maintaining efficient and reliable HVAC systems, having robust diagnostic tools at one’s disposal isn’t just a luxury—it’s an absolute necessity. As technology advances, HVAC equipment becomes more sophisticated. Consequently, the demand for equally advanced diagnostic tools that align with these complexities has shown significant growth. Technicians must adapt by wielding tools that can swiflty dissect and diagnose the intricacies of modern systems.

Navigating the extensive array of HVAC diagnostic tools can be daunting. Whether one is new to the field or a seasoned professional, understanding the available technology and its applications within HVAC systems is crucial for efficiency in both time and cost. This article will delve into precisely why these tools are indispensable, the variety available to professionals, and how their proper use not only streamlines maintenance but also prolongs equipment lifespan.

Today’s top-of-the-line diagnostic solutions allow swift identification of issues that could spell significant performance or safety concerns if left unchecked. Indeed, the continuously increasing reliance on data-driven decision-making in the HVAC industry underscores the importance of sophisticated diagnostic tools. We’ll explore the tangible impacts these tools have on service quality and the satisfaction of technicians and customers alike in our exploration of the state-of-the-art HVAC diagnostics.

Propelling HVAC Repairs into the Future with Innovative Diagnostic Tools

The HVAC industry is witnessing a significant transformation with the advent of innovative diagnostic tools. These advanced technologies are not only reshaping service delivery but are also setting new standards for efficiency and accuracy. Integrating smart diagnostics with HVAC systems enables technicians to pinpoint issues accurately, often before they become glaring problems. As such, personalized maintenance can be undertaken swiftly, effectively minimizing downtime. These tools are integral to ensuring long-term functionality and promoting sustainability within both residential and commercial settings.

Such diagnostic tools encompass a variety of features. These include thermal imaging, vibration analysis, and other sophisticated sensors that detect irregularities in system performance. By employing these tools, technicians can conduct comprehensive evaluations without the need for invasive inspections. This non-intrusive approach not only supports system integrity but also preserves the unit’s operational lifespan. Additionally, it allows for repairs to be completed with a level of precision previously unachievable, dramatically reducing the chance of recurring issues.

The incorporation of these tools into maintenance strategies has revolutionized customer service. No longer do clients face prolonged periods of inconvenience. Instead, the speed with which technicians can respond and resolve HVAC issues is unprecedented. By understanding and addressing problems quickly, customer satisfaction skyrockets. The ability to deliver prompt, effective repairs has become a powerful competitive edge within the HVAC market.

Yet, the journey towards widespread adoption of these tools is not without its challenges. Investment in training and equipment is necessary to reap the full benefits. Despite such upfront costs, the return on investment is evident in the enhanced quality of service and the extension of HVAC systems’ lifespans. Business owners who embrace these tools will find themselves at the forefront of the HVAC industry’s evolution.

The future of HVAC repairs looks promising thanks to these game-changing diagnostic tools. They are shifting the industry paradigm, offering intriguing possibilities for energy management and predictive maintenance. By embracing these advancements, the HVAC sector is set to thrive, characterized by innovation and bolstered by a commitment to excellence. Technicians prepared for this new era will enjoy a dynamic work environment where every problem presents an opportunity to showcase their expertise.

Bridging the Repair Gap: How Advanced Tools are Reshaping HVAC Servicing

The HVAC servicing sector is undergoing a significant transformation, thanks to advanced diagnostic tools. These innovative instruments enable rapid identification and resolution of system issues. The implementation of cutting-edge technologies, such as predictive analytics and AI-driven diagnostics, allows service professionals to foresee potential breakdowns, address them proactively, and reduce the likelihood of emergency call-outs. This strategic foresight embodies a leap forward in building management and preemptive repair work.

Equipped with these state-of-the-art tools, technicians gain a nuanced understanding of HVAC ecosystems. The data collected is not only extensive but also highly precise, covering various operational parameters, such as airflow, temperature differentials, and refrigerant levels. Such granularity in diagnostics transforms the troubleshooting process significantly. Technicians become adept at distinguishing between symptoms and root causes, leading to tailored solutions that result in longer-lasting repairs.

The enhanced efficiency of HVAC maintenance has wider implications. Effective repairs mirror directly on energy consumption patterns. With systems operating optimally, there is a noticeable decrease in energy usage, which translates to cost savings for consumers and a lower environmental impact. These outcomes are vital in promoting sustainable practices within the energy sector and contribute to the growing consciousness around eco-friendly technologies.

Moreover, the integration of these tools has elevated client-trust relationships. Advanced diagnostic reports provide transparency, allowing customers to visualize and understand the specifics of their system’s health. This openness fosters trust and reassures clients of the credibility and quality of service. Consequently, HVAC service providers can solidify their reputation as dependable partners in facility management.

These sophisticated tools not only bridge the repair gap but also open a new horizon for talent acquisition in the HVAC industry. As the field evolves, the demand for skilled professionals conversant with high-tech equipment rises. This evolution of skill sets not only benefits workers through enriching career pathways but also heightens the overall competency within the industry. The result is a robust and future-ready HVAC servicing landscape, built upon the pillars of technology, efficiency, and unyielding expertise.

The Emergence of Advanced Diagnostic Tools: A Boon for the HVAC Industry

The HVAC industry is enjoying a technological renaissance with the rise of advanced diagnostic tools. These modern marvels are revolutionizing the way systems are maintained, diagnosed, and repaired. Digital gauges, smart thermostats, and sensor-based monitoring systems are at the forefront of this innovation wave. Not only are they efficient, but they also provide real-time data analytics, which is critical for identifying and responding to system inefficiencies swiftly and effectively.

These tools are reshaping the methodology behind maintenance protocols. Traditionally, HVAC maintenance was often reactive—addressing problems only when they occurred. With new diagnostic technology, maintenance becomes proactive. Issues can be detected early on, even before they manifest into noticeable malfunctions. This change significantly reduces system downtime and service interruptions, which is highly beneficial for both service providers and consumers alike.

Such advancements in diagnostics have a direct impact on longevity and reliability of HVAC systems. Frequent breakdowns and inconsistent performance can be largely attributed to undetected or misdiagnosed issues. With comprehensive, precise diagnostics, thorough and long-lasting repairs can be assured. This is not just a question of replacing faulty parts but also refining system operation for optimized performance and reduced wear and tear.

The emergence of these tools is not without its impact on service itself. The knowledge and skillset required of HVAC technicians are expanding. There is a growing need for professionals who are adept in technology as much as they are in traditional repair skills. For competitive service providers, investing in their workforce’s training to handle such advanced equipment is now a top priority. They recognize that a well-trained technician is invaluable in delivering quality service in this new era.

Ultimately, the deployment of advanced diagnostic tools signals a significant win for the HVAC industry. Customers are assured greater reliability and quality, while service providers gain efficiency and new service offerings. It’s a dual-edged sword that slashes operational costs and enhances user experience. As the tools become more integrated into daily use, the full potential of how they can transform the industry will continue to unfold, promising ongoing improvements and innovation.

Redefining HVAC System Repairs: A Look at Technological Advancements

The epoch of HVAC system repair is being redefined by the emergence of advanced technological tools. These advancements are drastically enhancing the precision of diagnostics and the effectiveness of subsequent repairs. Through the integration of these technologies, HVAC systems are experiencing fewer failures and increased longevity, which is greatly beneficial to both consumers and service providers. The focus on technology ensures a shift from a replace-and-repair approach to a fine-tune-and-optimize model.

With each technological stride, HVAC diagnostics become more sophisticated. Gone are the days of speculative diagnoses based on generic symptoms. Repair technicians today are equipped with tools that provide detailed insights into system operations. These tools assess everything from airflow blockages to electrical system irregularities, allowing professionals to deliver a diagnosis grounded in accurate data rather than educated guesses.

The effectiveness of these tools extends beyond diagnostics to the realm of ongoing system monitoring. Sensors and intelligent controls can now predict issues before they escalate into major malfunctions. This proactive approach is redefining the relationship between system performance and maintenance, ensuring an HVAC system’s smooth operation without the need for frequent, costly repairs. These technological advancements contribute to the sustainability of HVAC systems by extending their useful lifespan.

Training and expertise occupy a central role in this technological overhaul. It’s no longer sufficient for HVAC technicians to rely solely on mechanical knowledge. A multifaceted expertise that embraces both the mechanical and digital realms of HVAC systems distinguishes the best in the field. For technicians, staying abreast of these advancements is a continuous pursuit, requiring them to participate in perpetual learning and skills development.

The redefinition of HVAC repair through technology is an ongoing process. It promises a future where efficiency, predictive maintenance, and sophisticated diagnostics converge to create a service paradigm focused on prevention rather than correction. This strategy optimizes resource use, saves energy, and fosters a culture where the advanced operation of HVAC systems is not just an expectation but the standard. Technicians, fleet-footed and armed with the latest gadgets, stand ready to deliver a service experience previously unimagined.

Game-changing Diagnostic Tools: Boosting Efficiency in HVAC System Repairs

The advancement of diagnostic tools in HVAC system repairs is a game-changer for the industry. Enhanced diagnostics empower technicians to rapidly identify and address HVAC system issues, reducing the time systems are out of operation. Precise identification of faults through advanced tools like digital manifolds and infrared cameras leads to a quick, cost-effective, and accurate repair process. This level of efficiency is a marked improvement over traditional methods, which were often time-consuming and prone to diagnostic errors.

These state-of-the-art tools also deliver increased system transparency. Real-time data access from remote diagnostics allows technicians to monitor HVAC systems without being on-site physically. This remote troubleshooting capability is redefining maintenance and repair protocols, providing the ability to accurately diagnose issues from a distance. As such, HVAC professionals can ensure that systems maintain optimal performance with minimal interruption to building occupants.

Moreover, advanced diagnostics significantly improve repair precision by providing detailed insights into system operations. When systems are fine-tuned to their peak performance using these tools, they operate more efficiently, consume less energy, and experience fewer breakdowns. This tight integration of diagnostics and repair exemplifies the technological synergy that today’s HVAC industry strives for. It also contributes to the sustainability of both the equipment and the environment, as there is less wastage of parts and resources.

The implications of these improvements are far-reaching. Not only do they reflect positively on the service quality, but they also impact customer satisfaction. In a market where consumers demand quick and reliable solutions, the ability to provide expedited yet accurate repairs is invaluable. It solidifies the trust customers place in service providers, establishing a reputation for dependability and expertise in the latest HVAC technologies.

Ultimately, the influence of these diagnostic tools transcends immediate repair efficiency. They are reshaping the very blueprint of the HVAC service industry. With such tools in place, future advancements are likely to further enhance not only repair work but also preventive maintenance strategies. This evolving landscape promises to refine the industry further, striving for an ultimate goal of excellence in service, energy efficiency, and customer satisfaction. As systems and technology evolve in tandem, the sky’s the limit for the heights HVAC servicing can reach.