In the realm of commercial and industrial refrigeration systems, the suction accumulator plays a crucial role and it’s positioned strategically to serve its function optimally. But where exactly is it located? To answer this, let’s first understand what a suction accumulator does. This vital component acts as a safeguard, preventing liquid refrigerant from entering the compressor – a scenario that could cause serious damage to the system.

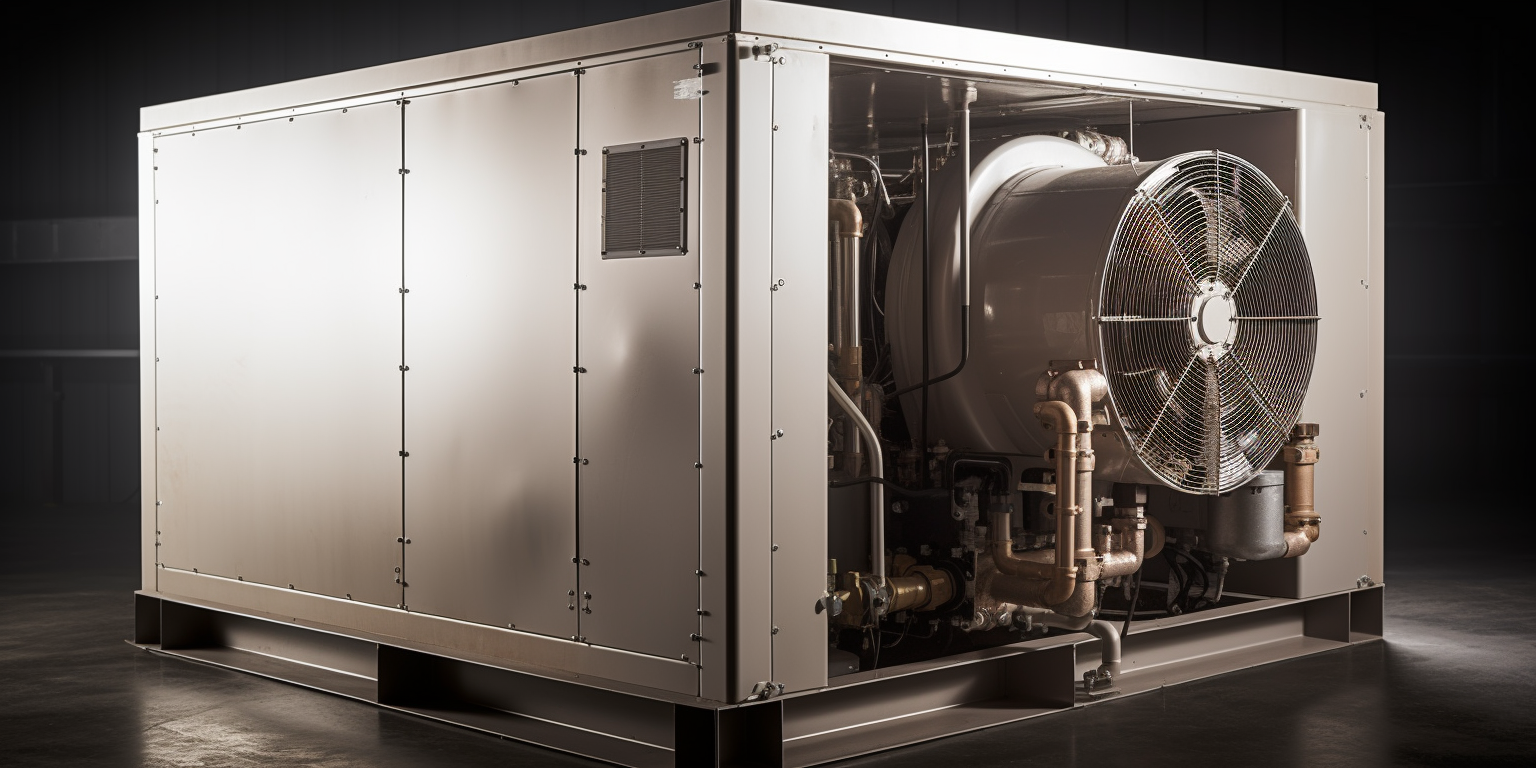

Now, to the heart of the question: the suction accumulator is typically found in the suction line, right before the compressor. Its position is no coincidence. By being situated here, the suction accumulator can efficiently catch any liquid refrigerant that might have made it through the evaporator without evaporating. The accumulator stores this refrigerant, gradually feeding it back into the system in a controlled, gaseous state. This ensures the compressor is protected from possible damage caused by liquid slugging, thereby ensuring the longevity of your commercial refrigeration unit.

While the suction accumulator might not be the most visible part of your commercial refrigeration system, its location in the suction line just before the compressor makes it a silent hero, safeguarding the system’s functionality and durability. It’s one of the many elements that underscores the importance of professional commercial refrigeration services in maintaining the health and effectiveness of your cooling units.

How does a suction accumulator prevent compressor damage?

A suction accumulator is a friendly hero that shields your compressor from potential harm. Picture this – you’re running your air conditioning system, and suddenly, liquid refrigerant bypasses the evaporator coil. This isn’t a good thing. Why? Because compressors are designed to pump gas, not liquid. That’s where our friend the suction accumulator steps in.

Acting like a vigilant guard, the suction accumulator catches this stray liquid before it can reach the compressor. It’s a simple yet effective design. The accumulator is a vessel located in the suction line, right before the compressor. Any refrigerant that enters this vessel gets temporarily held up. The gas refrigerant rises to the top and safely continues on its way to the compressor. Meanwhile, the liquid refrigerant stays behind, harmlessly pooling at the bottom.

But the suction accumulator isn’t just a detention center for rogue liquid refrigerant. It’s also a reform school. Within its walls, heat from the surrounding air warms up the liquid refrigerant, gradually transforming it into a gas. Once it has fully converted into gas, it can safely join its gaseous comrades on the journey to the compressor.

In this way, the suction accumulator plays a crucial role in protecting the compressor from potential damage. It is the unsung hero of your air conditioning system, quietly ensuring that everything keeps running smoothly.

What factors should be considered when selecting a suction accumulator for a specific refrigeration system?

When it comes to selecting a suction accumulator for a specific refrigeration system, there are several key factors to consider.

Firstly, the accumulator’s capacity is crucial. It must hold at least the same volume of refrigerant that the evaporator and all connecting lines can hold. This ensures that system components remain protected even during periods of high load.

The second factor to keep in mind is the working pressure of the accumulator. Just like any other pressure vessel, the accumulator should be capable of withstanding the system’s maximum working pressure.

The third consideration is the accumulator’s oil return. Make sure the accumulator has features that allow oil to return to the compressor effectively.

Lastly, pay attention to the construction material of the accumulator. It should be low in permeability and resistant to corrosion and extreme temperature fluctuations. Preferably, it should also be easy to install and maintain. Remember, the right suction accumulator can significantly increase the lifespan and efficiency of your refrigeration system.

How does the suction accumulator handle liquid slugs?

The suction accumulator plays an active role in managing liquid slugs. Think of it as a vigilant guard, constantly on the lookout for potential harm to your HVAC system. When the cooling cycle begins, the refrigerant transitions from a low-pressure, low-temperature vapor in the evaporator coil to a high-pressure, high-temperature vapor in the compressor.

Now, here’s where the suction accumulator steps up. In an ideal scenario, the refrigerant would flow into the compressor solely as a gas. However, sometimes, under certain conditions, this doesn’t happen. The refrigerant can enter the compressor as a liquid, creating what we call a ‘liquid slug’.

A liquid slug entering the compressor is bad news. You see, compressors are designed to handle gases, not liquids, and can be severely damaged by these slugs. That’s when a suction accumulator becomes a real ally. It acts as a reservoir, catching and holding onto these liquid slugs. Inside the accumulator, the refrigerant has some extra time and space to fully transition into a gas before moving on to the compressor.

To sum up, the suction accumulator actively guards your compressor by capturing any liquid refrigerant, giving it the chance to evaporate completely before it continues its journey. In doing so, the suction accumulator ensures the longevity of your HVAC system, saving costs on potential repairs and replacements. Using a suction accumulator is a smart, proactive way to protect your HVAC system from unnecessary damage.

How often should suction accumulators be inspected or serviced?

It’s crucial for the smooth running and longevity of your system to frequently inspect and service your suction accumulator. Generally, a good rule of thumb is to perform a thorough check once every six months under normal operating conditions. However, if your system is subjected to harsher conditions or heavier usage, you might want to consider more frequent evaluations, perhaps quarterly.

During these inspections, you’re looking for any signs of damage or wear and tear. Keep an eye out for dents, scratches, or corrosion, as these can compromise the accumulator’s efficiency. Additionally, pay close attention to the refrigerant levels. Insufficient refrigerant could indicate a leak, which needs immediate attention.

Regular servicing of your suction accumulator is also necessary. This includes cleaning and, if necessary, replacing worn-out components. Be sure to engage a trained professional for these tasks as they require specific knowledge and expertise. Professional servicing helps ensure that your suction accumulator operates at peak performance, thus extending its service life and saving you from costly repairs or replacements down the line.

Remember, preventative maintenance is always better than reactive maintenance. A well-maintained suction accumulator not only enhances system efficiency, but also contributes to a safer and more reliable operation. By inspecting and servicing your suction accumulator regularly, you can avoid unexpected breakdowns and ensure uninterrupted service.

Are there any specific maintenance guidelines for suction accumulators?

Maintaining your suction accumulator in top condition requires adherence to specific guidelines. Firstly, keep an eye on the accumulator’s refrigerant charge level. An inadequate refrigerant charge can cause your system to work harder than necessary and may lead to system failure.

Secondly, check the accumulator’s oil levels regularly. The oil in the accumulator acts as a lubricant, ensuring smooth operation. If the oil level is too low, it can cause friction and damage to the system components.

Next, make sure to clean the accumulator regularly. Dirt, sludge, and debris can build up over time and affect the performance of the accumulator. Use a gentle but effective cleaning solution and a soft cloth to wipe the exterior.

Finally, be sure to inspect the accumulator for any signs of damage or wear and tear. Look for cracks, leaks, or rust which could signal a problem. If you notice any of these signs, contact a professional immediately for repair or replacement.

Remember, regular maintenance of your suction accumulator will not only extend its lifespan but also ensure optimal performance of your HVAC system. So, take the time to follow these guidelines and keep your suction accumulator in great shape.

What are the potential consequences of not using a suction accumulator in a refrigeration system?

A suction accumulator is a crucial component in a refrigeration system. Without it, your system could face numerous potential issues. Let’s take a closer look at these.

Firstly, the absence of a suction accumulator can lead to the compressor flooding. This occurs when the refrigerant, instead of being in gaseous form, enters the compressor as a liquid. Compressors are designed to handle gases, not liquids, and this flooding can cause severe compressor damage over time.

Secondly, without a suction accumulator, oil logging can become a serious issue. The suction accumulator typically helps return oil to the compressor. Without it, the oil may be stuck in the evaporator, causing deficiency in the lubrication of the compressor parts. This could lead to increased wear and tear on these parts, reducing the lifespan of your compressor.

Finally, a suction accumulator aids in preventing the slugging phenomenon. Slugging refers to a situation where a large amount of liquid refrigerant enters the compressor all at once. This can cause significant mechanical damage to the compressor, which can be quite expensive to repair.

How can businesses diligently maintain Refrigeration System Parts?

Suction accumulators play a crucial role in the efficient operation of your refrigeration system. Regular maintenance of these components ensures their longevity and optimal performance. Let’s delve into how your business can diligently maintain the suction accumulators in your refrigeration system.

Firstly, make sure to frequently monitor the temperature near the outlet of the suction accumulator. If you notice a significant temperature drop, it could indicate an accumulation of liquid refrigerant. Addressing this promptly can prevent potential system damage.

In addition, implementing a regular cleaning schedule is key. Over time, oil and other contaminants may accumulate within the suction accumulator, which can interfere with its performance. Cleaning these components regularly can help to prevent such build-up and keep your system running smoothly.

Another easy but essential maintenance task is visual inspection. Regularly check for signs of rust, corrosion, or other physical damage. If you spot any issues, take immediate steps to repair or replace the affected parts.

Always remember to maintain an accurate and up-to-date system log. Recording temperatures, pressures, and other operational data can be invaluable in identifying any emerging issues. By being proactive, you can often prevent small problems from becoming large, costly repairs.

Software plays an essential role in maintaining the efficiency and longevity of vital components like suction accumulators. By monitoring parameters such as pressure, temperature, and fluid levels, software solutions can provide real-time data to technicians. This information enables predictive maintenance, helps to identify anomalies, and potentially prevents failures before they occur. For instance, if the software detects an abnormality in the pressure within the suction accumulator, it can alert the maintenance team to inspect and rectify the issue, preventing potential damage and downtime. Thus, software becomes an indispensable tool in managing the health of suction accumulators in refrigeration systems.

Key Takeaways:

- The suction accumulator plays a vital role in the operation of a refrigeration system; hence, maintaining it regularly is essential.

- Check the suction accumulator’s refrigerant charge level and oil level regularly as an inadequate charge or low oil level can lead to system failure.

- Regular cleaning of the accumulator helps prevent the build-up of dirt and sludge, ensuring optimal performance.

- Look for signs of damage, leaks or rust in the accumulator. If found, arrange for immediate repair or replacement.

- Without a suction accumulator, refrigeration systems could face potential issues like compressor flooding, oil logging, and the slugging phenomenon.

- Regular monitoring of temperature around the suction accumulator’s outlet, implementation of a regular cleaning schedule, and frequent visual inspections are recommended maintenance practices for businesses.

- Maintaining an accurate system log enables early detection of emerging issues and helps prevent costly repairs.

- Software solutions provide real-time data, facilitating predictive maintenance and early detection of potential failures. This can be instrumental in efficiently managing the health of suction accumulators.