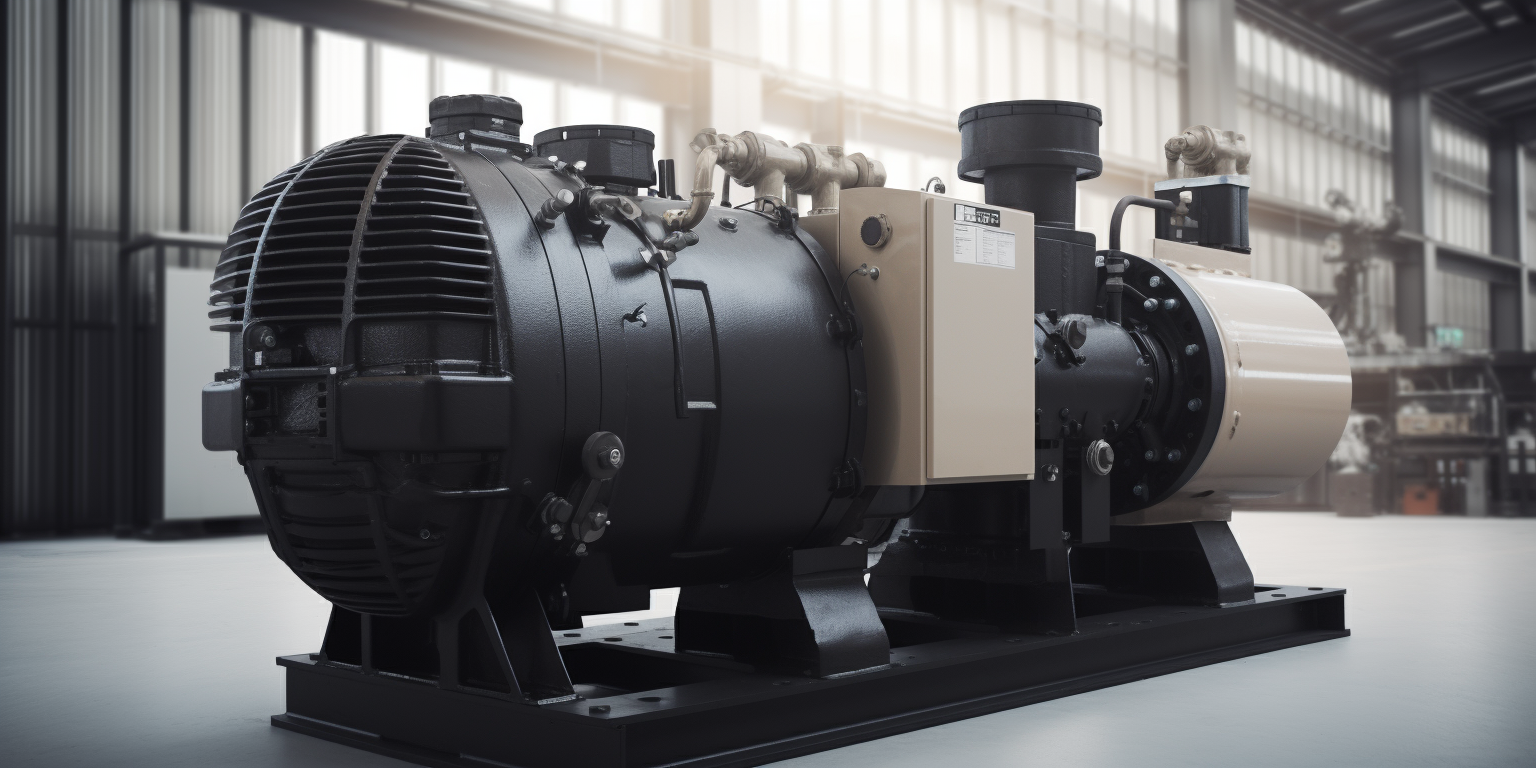

What Is A Screw Compressor? A screw compressor, often found in commercial and industrial refrigeration systems, is a unique piece of equipment that plays a vital role in cooling processes. At its core, a screw compressor is a type of gas compressor characterized by a pair of meshing helical screws, known as rotors.

When these rotors turn, they reduce the volume of the refrigerant gas, effectively increasing its pressure. This is the essence of how a screw compressor works. The gas, now at a higher pressure, can absorb more heat, making it ideal for cooling applications.

One of the biggest advantages of screw compressors is their efficiency. They are designed to operate continuously at full capacity without overheating, making them a reliable choice for industrial and commercial refrigeration. Moreover, they require less maintenance compared to other types of compressors, thanks to fewer moving parts.

Main components of a screw compressor

A screw compressor, a crucial component in industrial and commercial refrigeration systems, is composed of several key parts. Let’s break it down in a way that’s easy to understand!

First up is the pair of helical screws, also known as the rotors. These are the heart of the screw compressor and work together in a synchronized motion to compress the refrigerant. The male rotor, with its convex lobes, interlocks with the female rotor, which has concave flutes. Their spinning action draws in the refrigerant at the suction end and compresses it as it moves towards the discharge end.

Next is the motor, the powerhouse that drives the rotors. A strong, stable motor ensures the rotors spin at the right speed and in the right direction. The reliability and efficiency of the compressor largely depend on the performance of the motor.

The lubrication system is another essential part. It reduces friction between the rotors and other moving parts, preventing wear and tear, and helping to seal the spaces between the rotors to maximize efficiency.

Last but not least, we have the housing or casing, which encloses all these parts. It’s designed to withstand high pressures and provides a sturdy structure that protects the internal components from the external environment.

These are the main components of a screw compressor in a refrigeration system. Understanding these parts and their functions can help in maintaining the compressor and diagnosing any potential problems.

Advantages of using a screw compressor

A screw compressor, with its robust and efficient design, brings numerous advantages to refrigeration systems. Firstly, energy efficiency is a significant benefit. This type of compressor operates without a need for suction and discharge valves, reducing energy losses and enhancing performance.

Secondly, the screw compressor’s compact design makes it a space-saving solution. In the busy setup of a refrigeration system, where space can often be a premium, the compactness of the screw compressor is a significant advantage. Plus, the screw compressor’s simple design minimizes maintenance needs, saving both time and resources in the long run.

Moreover, the screw compressor exhibits less vibration and noise compared to other types of compressors. This contributes to a quieter working environment, which is better both for the machinery and for the people working nearby.

Another advantage is the screw compressor’s ability to handle high cooling capacities. It can easily adapt to fluctuating demands, making it an ideal choice for commercial and industrial refrigeration systems.

Finally, screw compressors are known for their reliability. With fewer moving parts, the likelihood of mechanical failure decreases, ensuring uninterrupted operation and reducing the need for frequent replacements.

Maintenance requirements for a screw compressor in refrigeration

A screw compressor, a vital component in refrigeration systems, requires regular maintenance to ensure optimal performance. First off, always prioritize the cleaning of the compressor’s air filter. A clean air filter enables your screw compressor to function efficiently while preventing dust and debris from clogging its system.

Oil levels also need to be checked regularly. Proper lubrication reduces friction between the screw compressor’s moving parts and prolongs its lifespan. If the oil level is low, fill it up to the recommended level. Remember to use the manufacturer-recommended oil to avoid any potential damage.

Beyond that, the compressor’s coolant level is another aspect that requires attention. A well-maintained coolant system allows for effective heat dissipation, ensuring the compressor doesn’t overheat. If the coolant level is low, refill it promptly.

Annually, plan for a more comprehensive check. This includes inspecting the belts, checking for leaks, and assessing the overall functionality of the compressor. Any worn-out parts should be replaced immediately to prevent more serious damage.

In addition, the compressor’s motor bearings need periodic lubrication and the alignment of the motor and compressor should be checked. If any unusual noise or vibration is detected, a professional should be consulted immediately.

Remember, the best way to maintain your screw compressor’s functionality and longevity in your refrigeration system is through consistent and thorough maintenance. Not only can this prevent unexpected breakdowns, but it can also lead to significant energy and cost savings in the long run.

Potential issues or problems that can occur with a screw compressor

A screw compressor, a key component in a refrigeration system, could face several issues affecting its performance.

One common problem is overheating. This can occur due to several reasons, like inadequate ventilation or faulty cooling mechanisms. If neglected, overheating can damage the compressor’s parts, making it less efficient or causing a complete breakdown. To resolve this, check the cooling mechanisms regularly and ensure proper ventilation around the compressor.

Another issue that can arise is oil leakage. This can deteriorate the compressor’s performance and could even lead to catastrophic failure. Regular inspection for oil leaks and prompt replacement of damaged seals can help prevent this problem.

Thirdly, the compressor can suffer from excessive vibration, usually resulting from incorrect installation or mechanical failure in one of the moving parts. Regular maintenance checks can help detect and rectify this problem early. Appropriate and regular balancing of the rotating parts can also minimize vibration.

In addition, contamination in the air intake can cause serious damage to the screw compressor. This can be prevented by ensuring that the air filters are clean and free of debris.

Lastly, a drop in pressure could indicate a number of issues, such as leaks, clogs, or component failure. Regular pressure checks and maintenance can help to identify these issues and mitigate them before they lead to larger problems.

Can a screw compressor be used in all types of refrigeration systems, or are there limitations?

A screw compressor, often a go-to choice for many applications, plays a significant role in the refrigeration industry. However, it’s essential to understand that while highly versatile, it may not be suitable for all types of refrigeration systems.

The efficiency of a screw compressor shines in large-scale refrigeration systems, particularly those that demand continuous and prolonged operation. These compressors are designed to handle heavy-duty tasks with remarkable efficiency and reliability, making them an excellent choice for industrial refrigeration or HVAC systems in large buildings.

While they are capable of handling significant refrigeration loads, screw compressors may not be the best option for smaller, residential refrigeration systems. This is mainly because these systems neither require the high capacity of a screw compressor nor justify the higher upfront cost associated with these compressors.

Another potential drawback is that screw compressors are less efficient at part-load operation. This means in applications where the load frequently varies or where the full capacity of the compressor is not often required, this equipment might not be the most energy-efficient choice.

How can software streamline the maintenance of Screw Compressors?

Screw compressors, essential in both industrial and commercial refrigeration, can greatly benefit from the application of specialized software to streamline their maintenance. To start with, software can serve as a tool for the comprehensive tracking of a screw compressor’s performance data. Real-time monitoring helps spot any deviations from optimal performance, facilitating immediate intervention and preventing potential system breakdowns.

Moreover, the software can set reminders for regular maintenance tasks, creating an organized schedule that can prolong the lifespan of your screw compressor. This approach ensures that all critical maintenance checks – from oil changes to assessing wear and tear of parts – are never overlooked.

Additionally, the software can log historical data, providing an invaluable reference point for identifying recurring issues or patterns over time. With these insights, technicians can predict potential future failures and take preventative measures, reducing downtime and saving costs.

Lastly, software can facilitate remote maintenance, particularly crucial in these times of social distancing. Technicians can access the system from anywhere, carry out diagnostics, and even perform some maintenance tasks without the necessity of physical presence. This flexibility can lead to increased efficiency and decreased response time for resolving issues.

Key Takeaways:

- A screw compressor is a vital component of a refrigeration system, but it can encounter problems such as overheating, oil leakage, excessive vibration, air intake contamination, and pressure drops. Regular maintenance and checks can mitigate these issues.

- While screw compressors are highly efficient for large-scale refrigeration systems requiring continuous operation, they might not be the best fit for small residential systems or applications with varied load requirements.

- The use of specialized software can significantly streamline the maintenance of screw compressors. It enables real-time performance monitoring, scheduled maintenance reminders, historical data logging, and facilitates remote maintenance, enhancing the compressor’s longevity, efficiency, and cost-effectiveness.