Cleanrooms are some of the most complex work in commercial construction. Cleanroom environments are designed to regulate airborne particles, temperature, humidity, pressure, and contamination risks.

These controlled environments, used in industries like pharmaceuticals, biotech, semiconductors, aerospace, and advanced manufacturing, demand extreme precision, tight coordination, and zero tolerance for error. That means every decision–from appropriate construction materials and sequencing to workforce access and equipment startup–has downstream consequences.

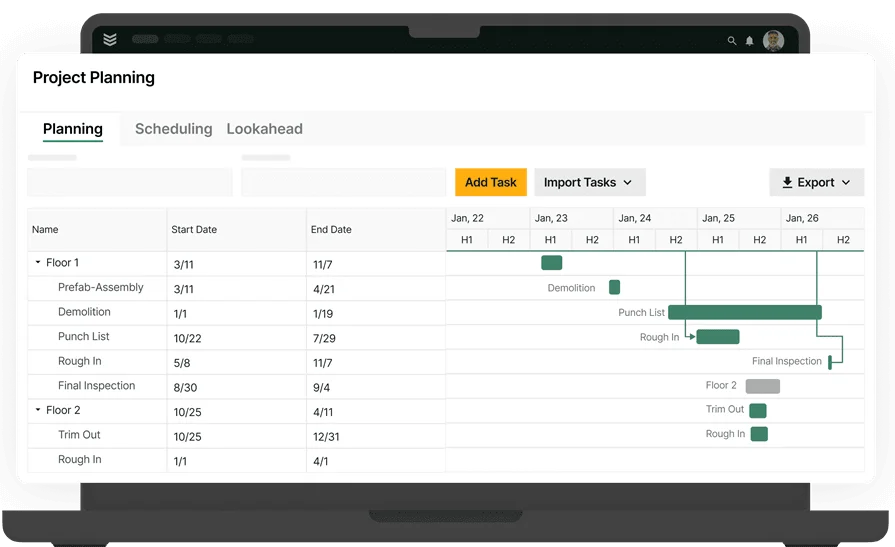

To manage complexity, 58% of contractors surveyed are investing in tools for high-stakes projects like cleanrooms, according to The Pivot Point, a recent report by BuildOps.

In this article, we’re going to cover:

- 5 stages of cleanroom design and construction projects

- Modular vs traditional construction for cleanroom integrity

- Where do most cleanroom construction companies go wrong with project mismanagement?

- 5 tips to bid on cleanroom projects better than the competition

- How to become a trusted cleanroom construction company

Let’s get started with how the cleanroom construction process actually works.

5 stages of cleanroom design and construction projects

The cleanroom construction process is successful when teams treat these five stages as one continuous system instead of disconnected handoffs.

1. Define the objective

Stage one is where the project’s non-negotiables are set. Construction and design teams lock in cleanroom components like:

- Cleanliness classification and environmental requirements

- Regulatory and validation standards

- Site constraints, utilities, and phasing realities

- Budget and schedule guardrails

If teams miss the mark here, every downstream decision gets harder and more expensive.

2. Engineer for performance

In this stage, concepts become buildable, coordinated plans. Teams focus on:

- HVAC systems, advanced filtration systems, and pressurization design

- Trade coordination and constructability

- Construction material selection and system integration

- Submittals and long-lead equipment planning

The goal is to create extremely specific and detailed designs that perform in the field.

3. Plan the work

Cleanroom construction projects are complex jobs that demand disciplined preconstruction. In this stage, teams:

- Sequence trades to maintain cleanliness and enable work progression

- Lock procurement timelines for critical equipment

- Set cost controls and change management processes

- Prepare crews for controlled site execution

Strong planning during preconstruction prevents surprises once boots hit the ground.

4. Build, test, prove

During the construction phase, execution matters most. Teams manage:

- Installation of enclosures, mission-critical systems, and cleanroom technology

- Strict access, cleaning, and sequencing protocols

- Testing, adjusting, and balancing (TAB)

- Commissioning and issue resolution

Construction isn’t done when the last project component is finished. Construction is done when all HVAC systems and other cleanroom components perform as designed.

5. Certify and turn over

The project becomes operational during this stage, which includes:

- Validation and certification (IQ/OQ/PQ)

- Final documentation and as-builts transfer

- Owner training and system handoff

- Maintenance readiness and service planning

A cleanroom only delivers value when it’s ready to run, and the owner is prepared to take over building operations.

Modular vs traditional construction for cleanroom integrity

Contractors must decide between traditional and modular construction to deliver cleanrooms. Understanding the tradeoffs of both methods is key to delivering cleanroom environments that perform from day one.

Modular construction

Modular cleanroom construction offers real advantages when speed, repeatability, and control matter most. Large portions of cleanroom components, like the walls, ceilings, MEP racks, and even entire rooms, can be fabricated off-site in controlled environments, then delivered and assembled on location. Off-site fabrication reduces exposure to weather, site congestion, and rework, while allowing parallel workstreams that can compress schedules.

The trade-off is less flexibility. Design changes late in the game are harder than with traditional construction.

Traditional construction

Traditional builds happen almost entirely in the field, with systems installed piece by piece. It gives teams more flexibility to adapt layouts, accommodate existing conditions, and make changes as requirements evolve.

That adaptability comes at a cost: longer schedules, higher levels of field coordination, and greater risk of rework if sequencing slips or documentation breaks down.

Where do most cleanroom construction companies go wrong with project mismanagement?

Without tight control over schedules, costs, and documentation, even experienced construction teams can watch a cleanroom project unravel. Understanding where projects typically break down is the first step to keeping them on track.

Underestimating coordination complexity

Cleanrooms demand tight choreography among trades, systems, and sequences. Without proper planning, trades work out of order, conflicts arise, and rework puts cleanliness and schedules at risk. When coordination lives in spreadsheets and meetings instead of real-time systems, problems show up late–when they’re hardest and most expensive to fix.

Letting costs drift into overages

Cleanroom margins erode quickly when costs aren’t tracked in real time. Specialized construction materials, long-lead equipment, and change orders add up, especially when scope changes aren’t tied back to labor and procurement impacts. Without tight cost control, small misses quietly turn into blown budgets.

Treating documentation as an afterthought

In cleanroom construction, documentation isn’t paperwork, it’s proof. Missed submittals, incomplete install records, or disconnected validation data can delay commissioning and certification, even if the physical work is done. When documentation is scattered across emails and folders, teams lose time chasing approvals instead of moving the job forward.

Deep Dive

AI-powered tools can really simplify these critical processes, with nearly 40% of contractors reporting using AI for admin and recordkeeping in BuildOps’ The Pivot Report survey of contractors across North America.

Breaking the link between field and office

Cleanroom projects move fast, and conditions change daily. When the field and office aren’t working from the same information, decisions lag and mistakes multiply. Crews install work based on outdated plans. Project managers react instead of lead. The gap between what’s happening onsite and what leadership sees creates risk no cleanroom can afford.

5 tips to bid on cleanroom projects better than the competition

Cleanroom bids are won by contractors that understand risk is part of the product. With more than 60% of contractors changing their bidding strategy to better meet project demands, according to The Pivot Point, pricing jobs appropriately will beat competitors that bid cleanrooms like standard commercial jobs.

- Price the risk: Strong bids account for controlled access, rework prevention, commissioning support, and documentation effort upfront.

- Show understanding about the build: The best bids clearly explain how the work will be executed, like trade sequencing, contamination controls, long-lead procurement, and commissioning strategy.

- Be honest about what’s excluded: Winning contractors are explicit about exclusions, owner responsibilities, and decision deadlines.

- Tie cost to control: Strong bids show how costs will be tracked, changes will be managed, and impacts will be communicated in real time.

- Prove project experience: Highlight relevant projects, lessons learned, and how the company has handled commissioning, validation, or late-stage changes.

Deep Dive

A whopping 91% of contractors surveyed reporting bidding is more competitive than ever. Using tools like BuildOps to create an impressive bid package can make or break your bottom line.

How to become a trusted cleanroom construction company

The contractors that owners trust most do things differently than traditional commercial construction contractors, and they do them consistently.

Lead with clarity, not confidence

Trusted cleanroom contractors are clear about scope, sequencing, risks, and decision points from day one. They explain what could go wrong and how they’ll handle it. That honesty builds credibility long before construction starts.

Control the work, don’t just track it

Trusted teams run the job with discipline: tight schedules, real-time cost tracking, and documented change management. They see issues early and act fast instead of waiting for monthly reports to surface problems.

Respect the validation process

For cleanrooms, construction isn’t the finish line–certification is. Companies that earn repeat work treat documentation, testing, and validation as core scope, not administrative cleanup.

AI can automate compliance tracking to support documentation and validation workflows. In fact, 40% of contractors surveyed report using tech to simplify the compliance process. When commissioning and IQ/OQ/PQ go smoothly, owners remember who made that possible.

Build for the operator, not just the turnover

The most trusted contractors consider maintainability, system access, and long-term performance during design and construction. Owners notice when a cleanroom runs reliably after crews leave, and they call those contractors again.

Communicate like a partner

Cleanroom projects evolve. Trusted contractors keep owners informed with clear, timely updates–especially when the news isn’t good. They don’t hide behind emails or meeting minutes. They solve problems in real time and keep decisions moving.

Mastering cleanroom construction comes down to controlling complexity at every stage–from early design decisions to final validation and turnover. Tools like BuildOps can improve operational efficiency to set contractors up for success on these complex construction projects.

With disciplined project management, clear communication, and the right technology supporting field and office teams, contractors avoid the industry’s most common pitfalls and establish themselves as the trusted partners cleanroom owners return to again and again.

250% profit increase

Contractors who use BuildOps see results on their commercial projects – learn how.