At enterprise scale, most contractors struggle because integrated ERP systems are not used consistently across business processes. Inconsistency is easy to ignore, but it becomes significant over time.

As companies grow across regions, service lines, and operating companies, execution naturally fragments. Different leaders make reasonable local decisions. Teams adapt tools to fit their workflows. Acquisitions bring their own existing systems and business processes. Over time, the organization ends up with technology everywhere—but ERP system alignment nowhere.

The result is a quiet operational tax.

- Data exists, but it doesn’t line up

- Knowledge lives in systems, but it doesn’t travel

- Leadership sees activity, yet still lacks clarity

That’s why enterprise resource planning software adoption at the enterprise level is less about features and far more about consistency. When adoption is treated as an execution strategy, not a technology project, software becomes a force multiplier instead of another layer of complexity.

In this article, we’re going to cover:

- Common enterprise resource planning (ERP) software integration challenges for construction teams

- 3 enterprise software user adoption strategies for construction contractors

- BuildOps: standardizing businesses processes across enterprise operations

Let’s start with the problem.

Common enterprise resource planning (ERP) software integration challenges for construction teams

For enterprise construction teams operating across multiple locations, enterprise resource planning challenges often stem from inconsistent usage across business units, not limitations in the ERP system itself.

As organizations rely on ERP software to manage core business processes–from supply chain management and inventory tracking to financial reporting and resource allocation–gaps in standardization create data silos, reduce data consistency, and undermine operational efficiency.

Decentralized use of ERP systems across branches and divisions

One of the most common challenges at enterprise scale is decentralized interpretation of shared systems and business processes. Even when every team technically uses the same ERP solution, they often use it differently.

Job statuses may mean different things in different regions. Cost codes may be applied inconsistently. Required fields in one branch may be optional in another. None of these differences appear dramatic on their own, but collectively they undermine comparability and trust in the data.

When leadership cannot rely on uniform definitions or workflows, reporting becomes an exercise in reconciliation rather than insight. The business begins operating as a collection of local operations instead of a unified enterprise.

Consistent training, standards, and verification keep all teams in all departments and regions on the same page. When all team members understand expectations, leadership can rely on technology and make better, data-driven decisions.

Where does your critical jobsite info live?

Read our guide on where job knowledge breaks down, and how to catch it early.

ERP system feature depth without process alignment

Enterprise software platforms are powerful by design. They offer flexibility, configurability, and extensive feature sets intended to support complex, large-scale operations. Without clear operational standards, however, that flexibility can become a liability.

Teams gravitate toward the path of least resistance. Fields are skipped to save time. Workflows are bypassed to keep jobs moving. Over time, exceptions become the norm, and the system no longer reflects how work is actually performed.

Feature depth does not create clarity on its own. Without aligned processes, it creates multiple versions of “correct,” each one slightly different,and each one costly at scale. A culture of accountability, where everyone knows what processes are expected, allows enterprise companies to get the most out of their ERP software.

Multiple ERP solutions across various business processes

In private equity-backed and multi-opco environments, software fragmentation is especially common. Different businesses often operate on different ERP platforms, legacy systems, field service tools, or financial systems, even when they share ownership and leadership.

This makes enterprise visibility difficult and slows integration efforts. Best practices remain siloed. Performance comparisons lose meaning. Leaders spend more time translating data than acting on it.

Without a shared operational backbone that streamlines processes, scale stops working in the organization’s favor. Instead of leverage, complexity increases.

Enterprise contractors should identify the right ERP software that’s capable of supporting the entire company. Then, ensure all businesses and departments are held accountable for using the single, integrated technology.

Supply chain and inventory management across multiple locations

Supply chain management and inventory management are where enterprise ERP solution integration challenges tend to surface first and hurt the most. At enterprise scale, materials, equipment, and parts move across branches, yards, jobsites, and service trucks, not just a single warehouse or a team. Resource allocation often is managed through a mix of local spreadsheets, vendor portals, and partially integrated systems in warehouse operations.

When ERP systems aren’t fully integrated across operations, inventory tracking visibility becomes fragmented. The challenge is aligning supply chain operations data with how work is actually executed. Without a unified view that connects resource allocation and jobs in real time, teams make decisions based on incomplete information.

At enterprise scale, resource management gaps compound quickly. Small inconsistencies in warehouse management and how inventory is logged, transferred, or consumed across locations create ripple effects that disrupt schedules and inflate costs. Without integrated ERP workflows, supply chain visibility becomes another area where local optimization undermines enterprise efficiency.

3 enterprise software user adoption strategies for construction contractors

Successful ERP implementation at the enterprise level depends on how consistently business processes and data management standards are applied across the organization.

Before any ERP platform can improve operational performance, leaders must align teams around standardized processes that govern how work is executed, measured, and reported. Treating ERP adoption as an ongoing operational metric helps ensure workflows remain consistent as the business grows.

1. Establish non-negotiable business processes and data management standards

At enterprise scale, consistency does not happen organically. Leaders and project management must clearly define which elements of execution must be standardized across the organization. This includes core workflows such as job setup, labor tracking, cost capture and other financial processes, and closeout standards. The fundamentals must be consistent if data is going to remain reliable.

Make sure teams understand consistency isn’t about limiting them. Consistency protects visibility, comparability, and decision-making speed at scale.

2. Align business processes before rolling out technology

Software adoption is far more effective when it follows process alignment. Before rolling out or expanding a platform, organizations should establish shared expectations around how work should be executed and measured.

When workflows become standardized processes first, the system reinforces good habits instead of fighting them. Adoption becomes easier because teams are not being asked to invent their own interpretations of how the software should be used.

3. Treat ERP platform adoption as an ongoing operational metric

Enterprise adoption must be evaluated through operational outcomes, not just login rates or training completion. When adoption is treated as a key operational metric, it stays aligned with business outcomes instead of drifting over time.

Leadership should have visibility into where workflows are being followed, where they are breaking down, and how those patterns correlate to performance indicators like margin, billing speed, and rework.

BuildOps: standardizing businesses processes across enterprise operations

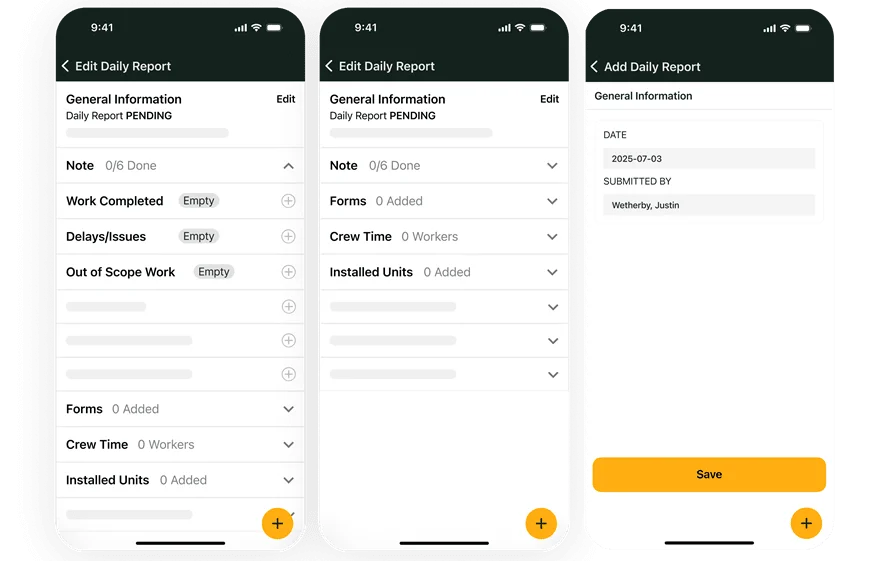

BuildOps was built specifically for enterprise commercial contractors managing complex operations across multiple locations, divisions, and service lines.

Rather than stitching together disconnected systems and historical data, BuildOps provides a unified, cloud ERP system that standardizes core ERP and field service workflows while still supporting the realities of large-scale operations. Job data, labor, materials, assets, and financials are connected in one system of action, giving leaders consistent visibility across the business.

By embedding operational efficiency and standards directly into workflows, BuildOps helps organizations drive consistency and improve customer satisfaction without slowing teams down. The system reinforces how work should be done, making adoption a natural extension of daily execution rather than an additional burden.

Approached correctly, adopting the right ERP systems is not about deploying tools. It is about creating clarity at scale, protecting it as the organization grows, and ensuring the business operates as one system.

BuildOps was designed to help enterprise construction teams achieve business growth through standardized execution, stronger visibility, improved operational efficiency, and scale that becomes a competitive advantage.

One size does not fit all

BuildOps is purpose-built for commercial teams like yours