Protecting lives is your mission.

Simplifying your field service work is ours.

Fire safety work can’t afford delays or missing records. BuildOps keeps teams connected so every job moves forward.

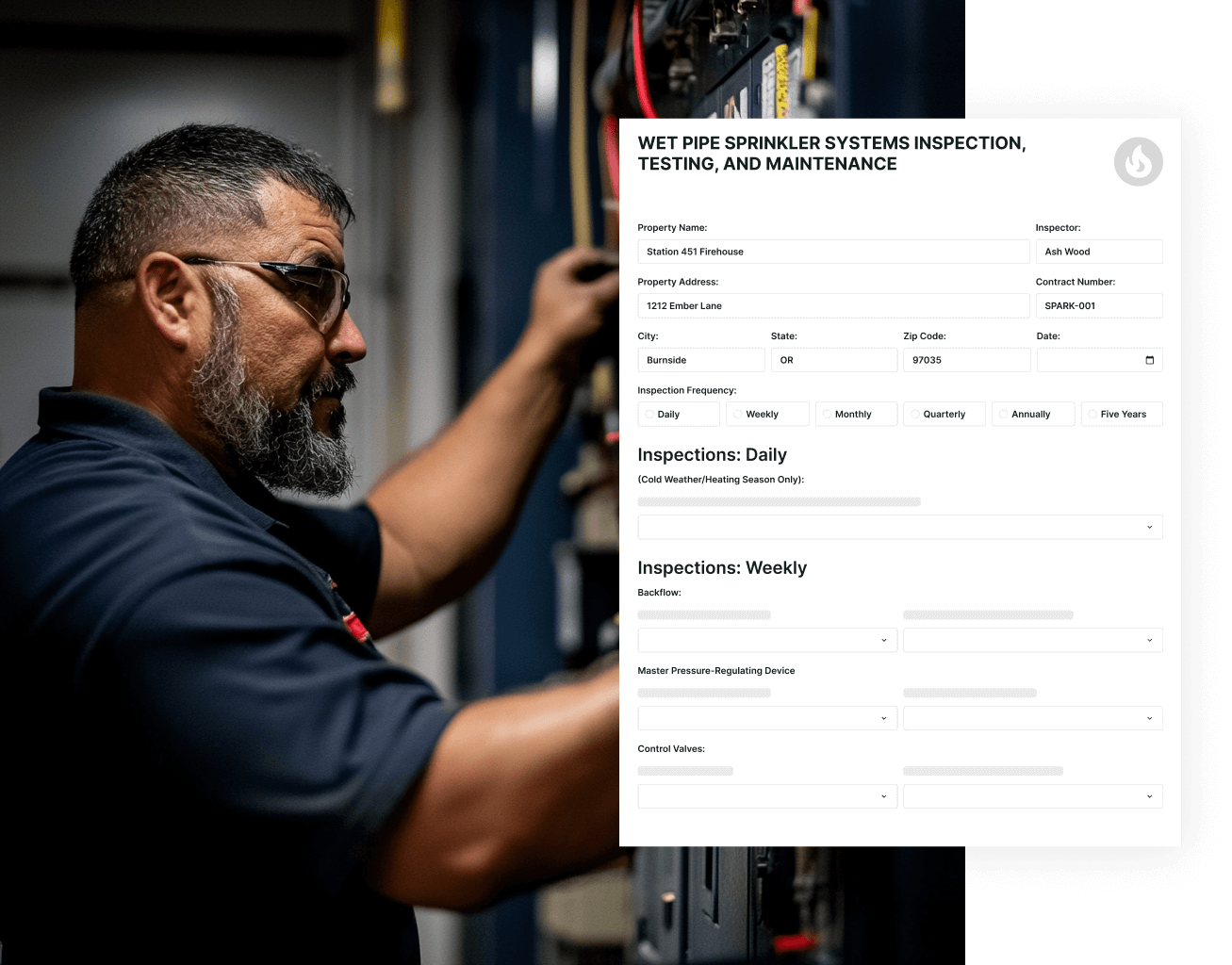

Inspections are the backbone of building safety. BuildOps helps your team stay organized and ready for every job.

BuildOps + Inspect Point

The old way: Techs finish inspections in one app, then re-enter everything just to quote, schedule, and invoice.

The new way: With BuildOps + Inspect Point, it’s a clean handoff—from inspection to quoting, scheduling, and invoicing, all in one connected workflow.

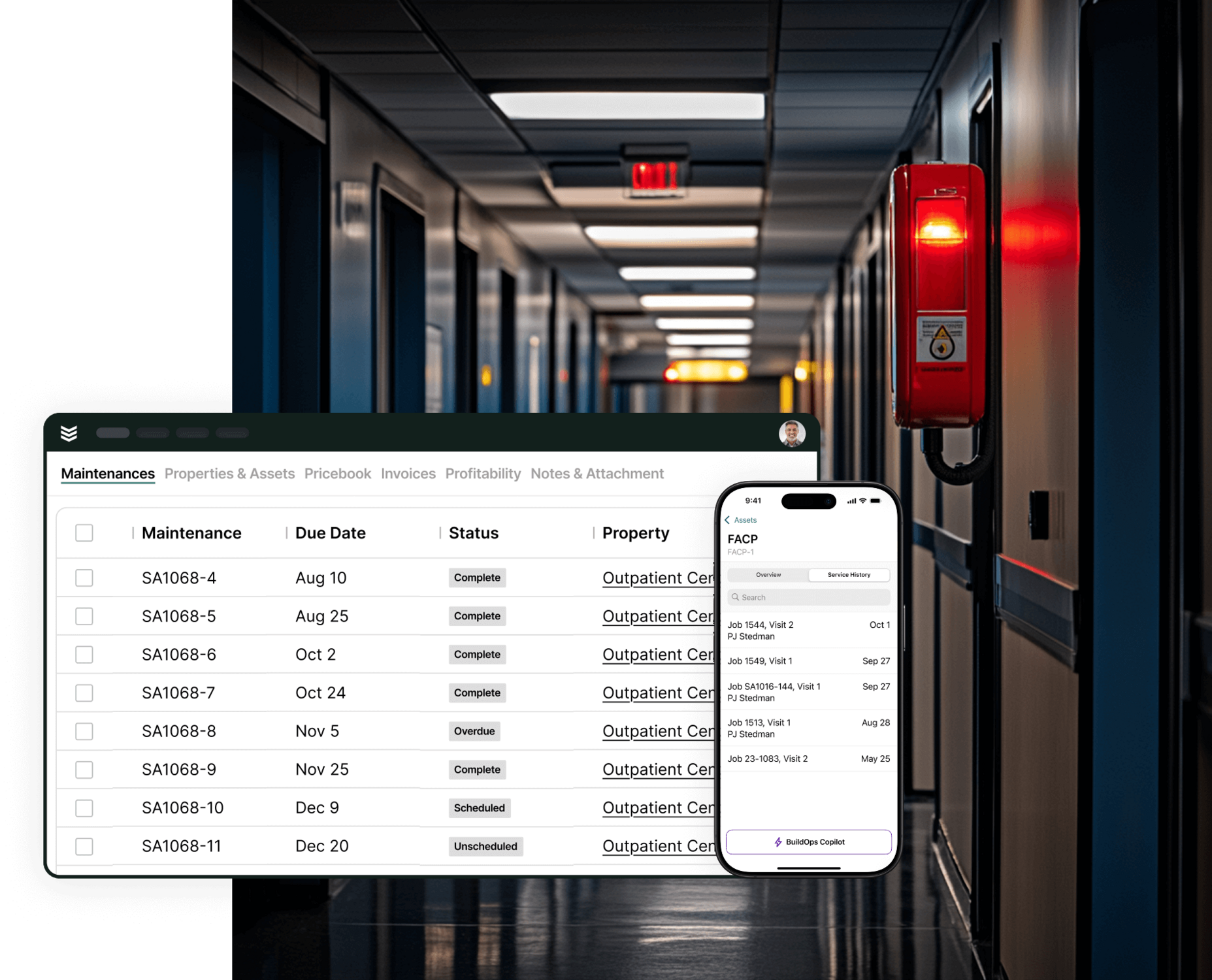

Maintenance isn’t just about compliance, but how you protect buildings, protect your customers, and build revenue that lasts.

Fire protection isn’t just reactive — it's relationship-driven. BuildOps helps you turn inspections into trusted partnerships and lasting contracts.

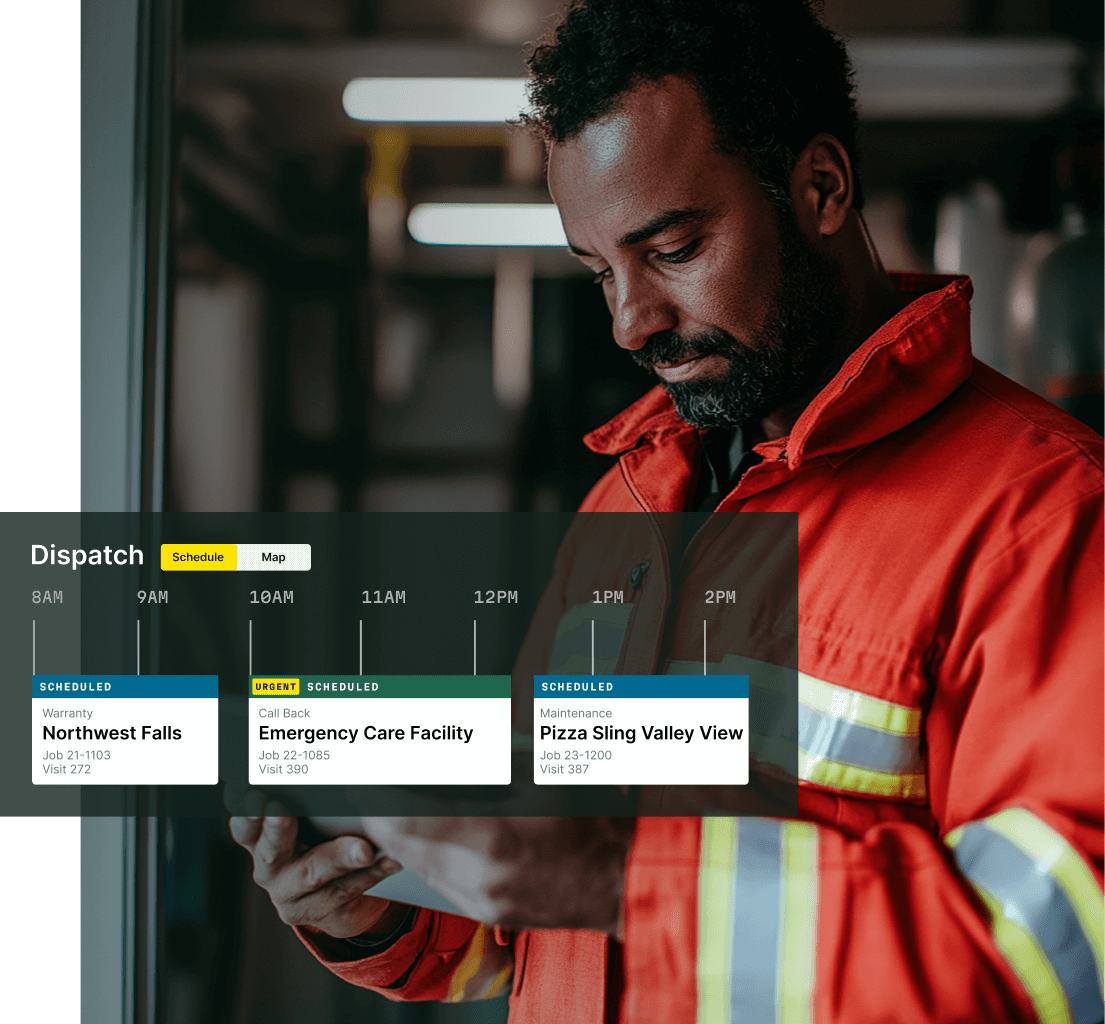

Mapping out the workloads and availability of all fire safety workers, leaving room for the last-minute changes that come with responding to calls.

Mapping out the workloads and availability of all fire safety workers, leaving room for the last-minute changes that come with responding to calls.

A way to respond to calls and work in real-time by sending the right fire safety worker to the job, and manage the calendars of all your contractors.

Offering your customers accurate estimates for the fire safety work you complete, and leverage historical data to cut down on estimating time.

Automated tracking for your fire & life safety workers that can be entered on the job, turned into field reports, and then automatically channeled right into invoices for your customers.

Sending invoices quickly is essential to unlocking cash flow, so send invoices to your customers with summaries accounting for all work, and then track everything you need like payments, late payments, and credit risks in a dashboard.

When you send out invoices, offer clear and easy ways for your customers to pay you with the method they want, making sure your customers are happier, and you get paid faster.

A fire safety field work mobile app for your techs that tracks necessary information like hours worked and their location, and lets them enter details on the job like what work was completed, what changed from quoting, and recommendations for future work.

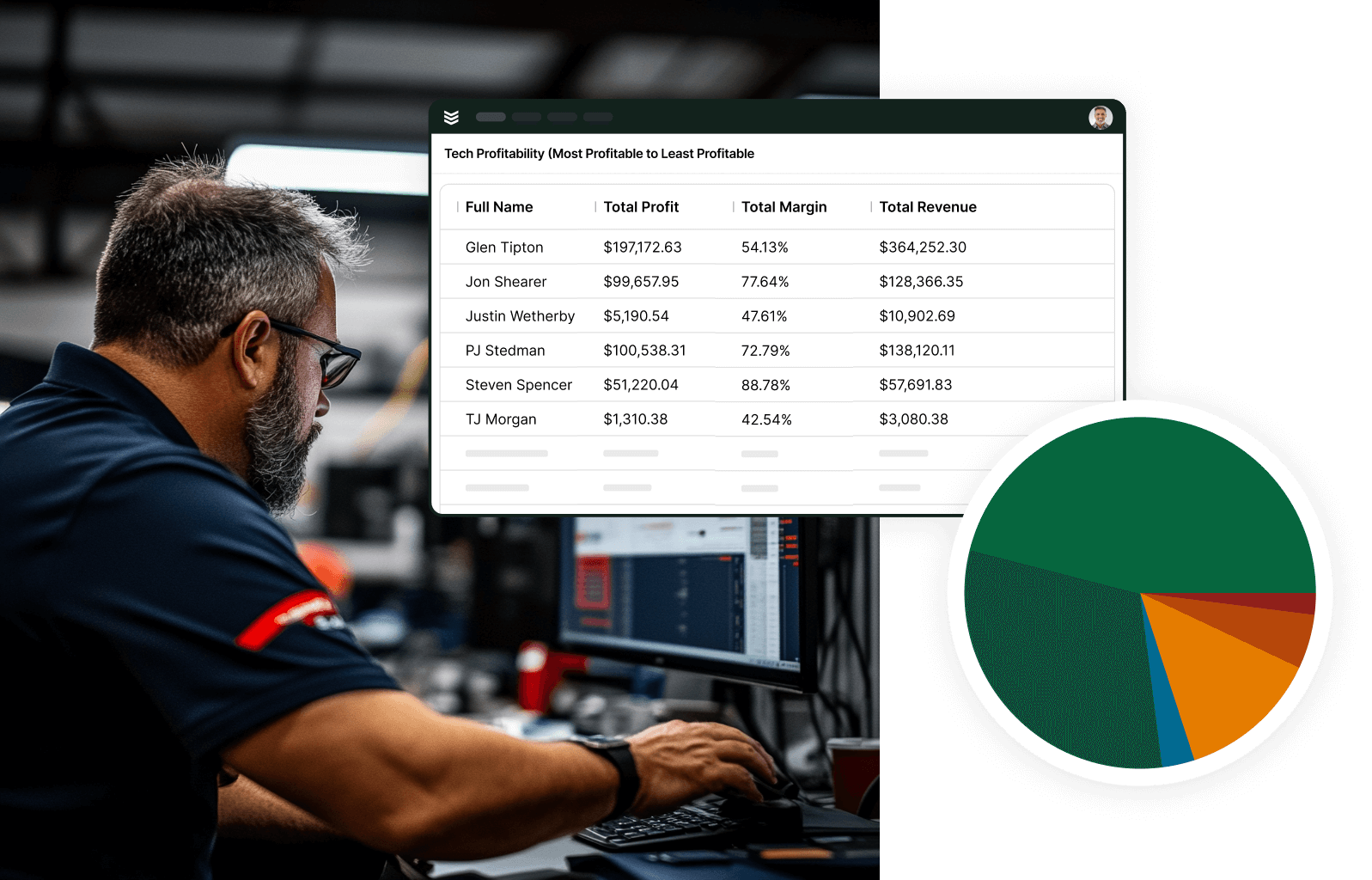

Gain insights on every aspect of your fire safety operations, grouped into custom dashboards that make sense for your business. See clear ways to fix inefficiencies, as well as your path to growth.

Build your own fire safety service agreements to create long-lasting relationships with your customers, pre-load your workflow, order parts in advance, and create predictable cashflow.

Fire safety work comes with a lot of equipment. Our add-on tool helps you keep track of it, link its use to your projects, and help you keep track of inefficiencies and downtime.

Seconds count in fire safety work, and our add-on CRM has all the information you need — like building codes, key contacts, and security information — easily searchable at the touch of a button.

Success Story

From months-long billing delays to 95% billable time, 54% revenue growth, and a 250% profit boost—Certified Fire turned inefficiency into growth with BuildOps.

Customer Stories

Every day, commercial fire & life safety contractors across North America count on BuildOps to keep their field service businesses running smoothly. Find out how we're helping the unsung heroes of the trades.

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

Capterra

With BuildOps, fire safety contractors have slashed billing time by 73%, grown revenue by 30%, and increased profits by 250%.

What can we do for you and your team?