When infrastructure projects get big, the cracks get loud.

Around the world, governments and private contractors take on massive builds, like data centers, rail lines, energy facilities. But no matter the project, they run into the same problems: underestimated risks, limited visibility, and warning signs that get missed until it’s too late.

As research and real-world cases have shown, when the systems behind these projects can’t scale, the result is a breakdown that calls attention to deeper issues across the entire subject of project delivery.

A McKinsey study of several hundred projects found cost overruns of at least 79% on average, with delays topping 50%. Nearly two-thirds of those were billion-dollar builds, showing that the worst overruns aren’t random. They cluster around the biggest, most complex builds, where scale itself becomes a risk factor.

But there’s a clear difference between the projects that spiral and the ones that stay steady. FMI found that while only 2.5% of contractors consistently hit both schedule and budget, those that plan well and follow structured processes hit or exceed profit targets 81% of the time.

In this post, we break down four operational failures that quietly kill major construction projects. If you want to avoid joining the list of projects with a dismal performance history, this is where to start. We’ll look at why vast construction schemes fail, where mega projects and risk collide, and what practical solutions commercial contractors can use to stay in control.

Top 4 reasons megaprojects carry oversized risks

As large-scale developments ramp up, familiar processes start to break down. Planning gets harder to control, risks increase, and decision making slows across teams. What feels manageable on smaller builds becomes fragile at scale.

That’s why large project failures tend to follow the same patterns. Below are the four operational breakdowns that show up again and again when projects outgrow their systems.

1. Huge projects expose system weaknesses

On a $2M job, missteps get patched. On a $1B development, they compound into serious problems.

Major projects run faster, heavier, and with far less breathing room than traditional work. Smaller scale projects use phased rollouts where you start a second building while wrapping up the first. But on a mega project, it’s a full-site blitz. Every structure is under construction at once with teams working across multiple shifts 24 hours a day.

“If there are enough human hours in a day to do the work, you could do it,” said Ben Burgett of Gray Construction. “But it just creates that much more effort at coordination. You have to give yourself some grace, because what we're doing right now is unprecedented.”

That kind of pace ramps up the strain on every part of the project. Most contractors' systems weren’t built for this pace. Execution starts to buckle under the weight of scale, visibility across crews and scopes gets murky, and small missteps start slipping through.

“The pressures are not for the faint of heart,” said Matt Landek, President of JLL’s Data Centers division. “Finding the staff is extremely difficult, the logistics are overwhelming, and there’s constant pressure…”

It’s in that pressure cooker where the early signs of failure start to show, but they don’t have to spiral. With real-time visibility into crews, tasks, and timelines, teams can identify risks early, adjust fast, and avoid becoming the next failed project.

2. Teams lose sight of budget and risks

Thirty percent of contractors say fragmented systems are slowing them down, and on a huge project, that kind of friction opens the door to real operational risks. As cases examined across the industry show, these delays eat into efficiency, fuel budget over runs, and compound risks.

“Teams with outdated tools are stuck hopping between different apps and systems,” says Grant Spiegel, Enterprise Commercial Success Manager at BuildOps. “With an all-in-one system, [workers aren’t] juggling 12 logins just to do the basics.”

This lack of integration creates breakdowns across the entire project. When field crews operate without up-to-date information, rework and delays become common. Office teams lose visibility into progress, which makes it harder to catch issues before they escalate. Over time, these gaps increase costs, slow schedules, and weaken performance.

To manage large-scale construction efficiently, teams need a centralized platform that connects every part of the operation. When scheduling, procurement, and field activity all run through one system, contractors can reduce risk, control budget over runs, and respond before small problems turn into major setbacks.

AI-driven insights from top commercial contractors

Want to see more data on the future of commercial contracting? Read our report.

3. Missed details spiral into financial nightmares

On smaller jobs, mistakes usually have predictable outcomes. A late delivery causes a short delay. A missed step leads to some rework. That’s a ripple effect. It's contained and easy to trace.

But on big projects, things don’t move in straight lines. That’s where the ricochet effect shows up. A design tweak in one trade can delay inspections, push back procurement, and spike project costs in scopes that weren’t even part of the original change. That’s how small issues can snowball into cost overruns and full-blown financial nightmares.

Without real-time visibility into labor, material flow, and task status, these chain reactions go unnoticed until it’s too late. Avoiding that kind of cascade requires connected systems, shared data, and fast feedback loops that give every team, from the office to the field, a clear view of what’s shifting, when, and why.

4. Poor decision-making derails project implementation

Large-scale infrastructure projects are rarely owned by a single team. Developers, contractors, subcontractors, and even governments all have a stake, and their priorities don’t always align.

Over many years, decision-makers come and go. Institutional knowledge disappears, scope changes get rehashed, and progress slows despite all the effort spent justifying project implementation at the start.

That kind of churn isn’t something your team can prevent, but it does make your own continuity and coordination even more critical.

When leadership turns over and assumptions are handed down without context, projects become especially vulnerable to optimism bias. That’s the tendency to underestimate risks and move forward based on outdated or overly hopeful estimates. Systematic bias builds early and lingers, making it harder for teams to reset expectations or catch risks before they grow.

Research from industry leaders and cited scholars shows that poor coordination, weak oversight, and incomplete early planning education are top reasons large-scale development efforts stall or fail to deliver. And while you may not control the whole ecosystem's project management, you can build a process that keeps your teams aligned, informed, and moving.

Expert Tip

The right field service project management software gives commercial contractors the internal structure to operate with clarity and control. When development stakeholders shift, your team doesn’t lose momentum. Context stays intact, task history is traceable, and handoffs don’t mean starting from scratch.

4 examples of failed megaprojects and what caused them

Large infrastructure ventures and vast construction schemes nearly always draw headlines, sometimes for extraordinary accomplishments, but more often for financial nightmares or an often dismal performance history. The stories below offer a fascinating look at what happens when ambitious builds meet fractured systems, and when coordination, visibility, and planning fail to scale.

Each is a fascinating account of what goes wrong in large-scale public works projects and formidable undertakings funded by a mix of private capital and government dollars. These examples from around the world are vastly reinforced by decades of research and serve as cautionary tales for anyone concerned with controlling risk in today’s capital project environment.

1. The Channel Tunnel: cost overruns and benefit shortfalls

The Channel Tunnel is a standout case in failed mega projects, not for poor engineering, but for poor execution. Built by 10 separate construction firms, it lacked unified leadership and effective project management. Optimism bias drove inflated forecasts, while real-time data gaps and underestimating costs led to a 60% cost overrun.

For major infrastructure projects like this, success depends not just on building infrastructure but managing it with real-time visibility, accountability, and scalable systems from the first phase onward.

What went wrong:

- Optimism bias and systematic misinformation in early estimates

- Key leadership turnover caused knowledge gaps

- 10 different construction companies operating in silos

Takeaway: Even the most technically sound rail projects can unravel without a unified system for decisions and leadership, especially when a large development stretches across borders and decades.

2. Big Dig: when visibility and coordination fail

Boston’s Central Artery/Tunnel Project, better known as the “Big Dig,” is a textbook example of how a megaproject spirals when visibility and coordination break down. Originally estimated at $2.8 billion, the project ultimately cost nearly $22 billion and finished many years behind schedule.

What went wrong:

- 118 separate contracts with limited cross-project coordination

- Heavy reliance on paper documents and disconnected planning processes

- Design changes and scope adjustments cascading without real-time alignment

Takeaway: Without a single, real-time operational view connecting teams, schedules, and costs, even the largest capital projects struggle to stay in control.

3. California High‑Speed Rail: cost overruns and schedule drift

Originally pitched as an 800‑mile rail line between Los Angeles and San Francisco, California’s High‑Speed Rail has become a cautionary example of scale without structure. The budget has ballooned from $40 billion to over $135 billion, and a system once promised by 2020 may not be completed until the 2040s.

What went wrong:

- Contractor contracts issued prematurely, resulting in $100 million+ in delay claims

- Fragmented coordination across agencies, contractors, and phases

- Optimism bias in early cost, schedule, and risk assumptions

Takeaway: When multiple stakeholders operate with different versions of the plan, you get rising “invisible costs” long before schedules slip.

4. Flamanville 3 Nuclear Reactor: small errors, massive setbacks

Originally budgeted at $4.9 billion, France’s Flamanville 3 nuclear reactor is now expected to cost over $14.2 billion and has taken more than a decade to complete. Faulty welds, corroded safety valves, and repeated regulatory setbacks drove years of delay and billions in added cost. Even after startup, the reactor will shut down again to replace a core vessel component to meet compliance standards.

Flamanville highlights a growing challenge across major construction projects: 58% of contractors now say code compliance consumes more resources than any other phase. When visibility is limited and documentation isn’t streamlined, small errors, especially around safety and quality, turn into expensive, time-consuming resets.

What went wrong:

- Early quality issues weren’t caught in time to avoid expensive rework

- Safety and compliance failures forced regulatory resets and retroactive fixes

Takeaway: Flamanville 3 shows how limited real-time visibility on quality, inspections, and compliance can turn early issues into cascading delays and massive cost overruns on a nuclear reactor project.

Don’t make the same mistakes on your next big project, and ensure you have the right tools in place to scale properly, to manage your labor effectively, and to notice mistakes before they get out of control and become too costly. Having an end-to-end commercial construction project management tool in place will help you before you start your next big project.

BuildOps is purpose-built for commercial teams to navigate exactly these kinds of megaproject challenges. Set up a demo with our experts today to see how BuildOps features can help you stay on track and avoid overruns on your next big project.

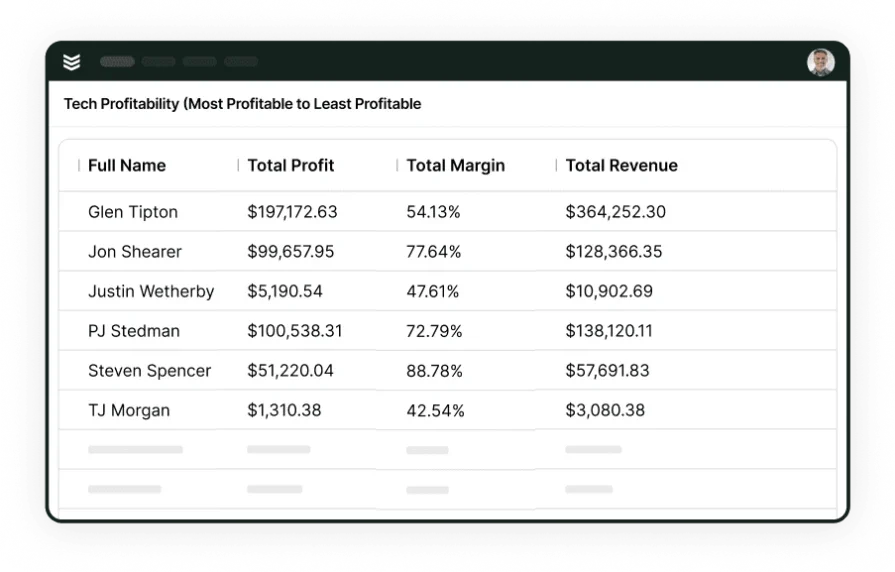

Our customers increase profits by 250%

See how they did it using our commercial construction project management tools