You’ve run enough peak seasons to know chaos comes from gaps in your HVAC company structure. When roles blur, dispatch stalls, handoffs break, and profit slips. This guide shows how structure drives field service management across the HVAC industry, from emergency service and PM contracts to quoted repairs and install work. The goal is simple: clean ownership, clean handoffs, and a crew that moves from call to close without friction.

- Why the structure of your HVAC company matters

- How an HVAC company is typically structured

- How to build and manage a successful HVAC team

We’ll start by tying structure to speed, margin, and accountability in the field and the office. Then we’ll map a proven layout for an HVAC shop and set up the roles, tools, and workflows that keep techs productive and billing accurate.

Why the structure of your HVAC company matters

HVAC company structure sets the pace for every call. Clear lanes for service, install, and projects stop finger-pointing and keep trucks moving. When the org defines who owns triage, estimates, dispatch, and billing, tickets move fast and margins hold. Techs see complete work orders, and the office sees clean data.

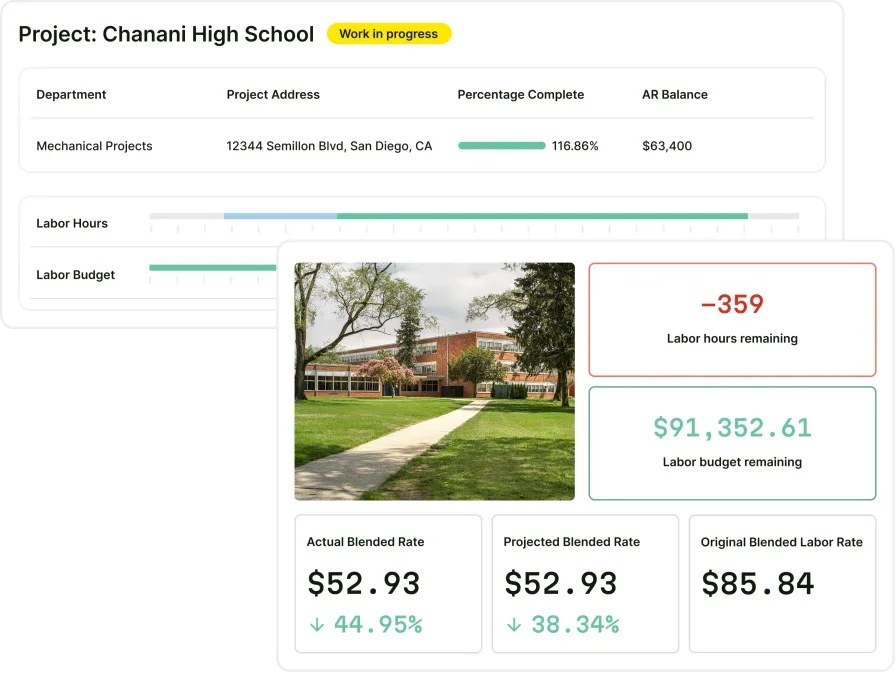

Strong structure pairs well with field service management. Scheduling assigns the best tech by skill and route. Checklists standardize diagnostics. Job costs and parts track against budget in real time. That reduces callbacks, protects SLAs, and shortens days sales outstanding.

Structure also builds a career ladder. Lead techs coach apprentices. Foremen and service managers step out of the van to run crews, quotes, and change orders. You keep talent, raise safety standards, and give customers a consistent experience.

How an HVAC company is typically structured

A durable HVAC company structure lines up the work you already do every day: urgent service, PM contracts, quoted repairs, retrofits, and construction. The goal is simple—clear ownership and the same path from lead to invoice. Field service management sits at the center so dispatch, inventory, and job costing run in sync, not in silos.

- Owners / Executive Team: Sets direction, protects cash, and allocates resources across service and construction; core seats include Owner/President, COO, CFO, VP of Service or Construction

- Sales / Marketing Team: Fills the pipeline and prices work with tight handoffs to ops; core seats include Sales Manager, Account Executive, Estimator, Marketing Coordinator

- Customer Service Team: Handles intake, triage, schedule windows, and status updates; core seats include CSR Lead, Service Coordinator, After-hours Desk

- Dispatchers: Balances capacity, routes efficiently, and manages escalations; core seats include Lead Dispatcher, Service Scheduler, Dispatch Analyst

- Field Technicians: Executes diagnostics, PMs, change-outs, startups, and documentation; core seats include Senior Service Tech, Installer Foreman, Controls Tech, Apprentice

- Project Management / Install Operations: Owns submittals, procurement handoff, schedule, QA/QC, and change orders; core seats include Project Manager, Assistant PM, Field Foreman, Sheet Metal Lead

- Warehouse / Parts & Procurement: Manages inventory, vendor relationships, truck stock, and parts runs; core seats include Purchasing Manager, Warehouse Lead, Parts Runner

This layout creates accountable lanes, faster dispatching, cleaner handoffs, and predictable billing. With FSM tools mirroring the org, techs see complete work orders, managers see real-time costs, and finance bills accurately.

For data-driven growth benchmarks and practical plays, see the report in the form below. Next, we’ll dig into how to build and manage a successful HVAC team using this structure in the field and in the office.

Unlock data-driven HVAC growth insights

See how leading HVAC shops use field data to sharpen dispatch, margins, and growth

How to build and manage a successful HVAC team

A strong HVAC company structure turns busy days into predictable outcomes. Set clear lanes, tie each lane to measurable results, and give field and office teams a single playbook. The steps below focus on what seasoned contractors use to keep crews productive and customers loyal.

1. Establish the company structure and framework

Lay out departments for Service, Projects/Install, Preventive Maintenance, Sales/Estimating, Customer Service, Dispatch, Warehouse/Procurement, Safety/HR, and Finance. Map each work type to one owner and define how a call moves from intake to invoice. Align those lanes with how your shop earns revenue across service, retrofit, and construction. For context on market mix and workload patterns in commercial HVAC, review how those segments pull on staffing and scheduling.

2. Define key roles and responsibilities

Write job descriptions that focus on decisions, handoffs, and KPIs. Spell out who approves quotes, who pulls parts, who closes tickets, and who finalizes invoices. Give lead techs authority on diagnostics and callbacks. Give project managers control of buyouts and change orders. Standardize how estimators scope work and present pricing; this overview of HVAC proposals outlines essentials that help sales sync with operations.

3. Establish clear guidelines and procedures

Create short, visual SOPs for intake, triage, diagnostics, PM scopes, materials control, commissioning, and closeout. Require photos, readings, and signatures on every ticket. Set rules for truck stock, returns, and refrigerant logs. Lock down a billing sequence that moves from work order to invoice without a rewrite; the primer on HVAC billing covers steps that keep AR clean and cash moving.

4. Perfect team member onboarding and training

Build a skill ladder that lists core competencies, from heat pump startups to VAV troubleshooting and controls integration. Pair apprentices with senior techs on PM routes. Add lab time for diagnostics and brazing. Track progress by competency, not just time in seat. Promote installers who can plan materials and read submittals into foreman roles, then into project management.

5. Streamline communication between teams

Run a simple cadence: morning huddles for safety and priorities, look-ahead planning midweek, and short debriefs on callbacks or change orders. Keep one source of truth for schedule, notes, and parts. Set written standards for CSRs and dispatch. For staffing profiles and daily rhythms that keep trucks moving, this look at the HVAC dispatcher role explains what high performers track and how they prevent idle time.

6. Leverage technology to optimize operations

Adopt field service management that mirrors your lanes. Use skill-based scheduling, capacity planning, GPS timecards, mobile work orders, photo and checklist capture, inventory control, and live job costing with accounting sync. Techs close tickets in the field. Managers see costs in real time. Finance invoices the same day. Keep the setup simple, train in short reps, and audit data weekly so the system stays trustworthy.

A strong HVAC company structure ties everything together. Clear lanes for service, PM, install, and projects create fast handoffs from intake to invoice. Roles, SOPs, and a simple communication rhythm keep techs focused on quality work while managers watch costs in real time. Add training that grows apprentices into leads and use technology that mirrors how your shop actually runs. That is how a busy calendar turns into predictable revenue and steady customer loyalty.

If you want an all-in-one platform for commercial field service that mirrors your structure and supports dispatch, work orders, PM contracts, projects, and billing, BuildOps can help you run that playbook without extra paperwork or guesswork.

Looking to see this in action for your own operation? Take a short demo, click through the workflows, and decide if it fits your team. No pressure, just a hands-on look at how the pieces work together.

See 30% revenue growth with BuildOps

Streamline every part of your HVAC operation, optimizing your whole team’s performance