Pricing HVAC jobs isn’t guesswork—it’s survival. One bad estimate can wipe out the profit from three solid ones. If you’ve ever underbid a project or had a customer question every line on your invoice, you already know how critical smart HVAC pricing is. Whether you're handling installs, maintenance plans, or emergency calls, every number you write down affects your bottom line.

This guide is built for contractors in the HVAC industry who want pricing that works in the real world—where fuel costs spike, customers shop around, and your crew doesn’t have time to redo estimates. We’ll walk through how top HVAC pros break down their numbers, which pricing models actually work, and what it takes to stay competitive without selling yourself short.

And when it's time to get paid, sending that invoice on time matters just as much as how it's priced. Data shows the invoicing sweet spot is within 10 days after the job’s done—miss that window, and you could be chasing payments for weeks.

Here’s what you’ll find inside:

- 6 common HVAC pricing models contractors actually use

- Key costs that go into estimating for HVAC

- Step-by-step: How to build your HVAC service pricing

- Real-world examples of HVAC pricing in action

- How to price HVAC jobs for optimal returns

Knowing how to price your work is just as important as doing the work itself. Let’s break down what goes into getting those numbers right.

6 common HVAC pricing models contractors actually use

Every HVAC shop has its own way of handling pricing—and for good reason. What works for a residential maintenance plan might completely fall apart on a commercial install. Picking the right HVAC pricing model gives you the control to cover your costs, hit your margins, and stay flexible with customer needs. Here are six pricing models HVAC contractors commonly use, with notes on when each one makes sense:

- Flat rate - You charge a set price for a job no matter how long it takes. This model works best when the job type is predictable—like seasonal tune-ups or installing a standard mini-split. It makes billing easy and helps avoid customer disputes, but you’ll want solid data to make sure your flat rates actually reflect the effort involved.

- Time and materials - For work that’s tougher to predict—like troubleshooting complex issues or replacing parts in aging systems—you charge for hours worked and materials used. It’s transparent and flexible, but it requires precise tracking so you don’t eat costs or surprise the customer.

- Tiered pricing - This “basic, standard, premium” approach lets you bundle HVAC services into levels. For example, a basic package might include a quick inspection, while the premium covers cleaning coils, testing airflow, and checking refrigerant. This model gives customers options and helps you upsell without pressure.

- Subscription-based - You offer recurring service agreements—monthly or annually—for things like preventative maintenance or priority scheduling. Subscription plans help stabilize cash flow and keep your team booked year-round. It’s a go-to strategy for building loyalty while smoothing out revenue.

- Cost-plus - You calculate the cost of labor, materials, and overhead—then tack on a markup. It’s common for installs or replacements where there’s significant variation in system size and complexity. You’ll need accurate job costing to avoid underbidding, but it can be a reliable way to stay profitable.

- Value-based - This model focuses on what the service is worth to the customer, not just what it costs you. Emergency repairs during a heatwave? You price based on urgency and demand. It works well when your crew offers specialized expertise or fast turnarounds that other contractors can’t match.

Each model has its place depending on job type, customer expectations, and how you operate. A good HVAC pricing strategy often mixes these models based on the situation. Next, we’ll get into what goes into estimating for HVAC—so you can price your work with confidence, no matter which model you’re using.

Key costs that go into estimating for HVAC

Pricing HVAC jobs starts with understanding your actual costs—not just the parts and labor, but every moving piece that goes into getting the job done right. Miss something in the estimate, and you’re either eating into your profit or overcharging and scaring off work.

If you’re serious about dialing in your HVAC service pricing, you need to factor in the full scope of what it takes to deliver that service. Here’s what contractors track when estimating for HVAC projects:

- Labor - How much time your crew needs to complete the job, and what level of skill is required. A senior tech working on a commercial rooftop unit? That rate should reflect their experience and the complexity of the work.

- Materials and system components - From refrigerant and copper piping to air handlers and mini-split units—materials can add up fast. Pricing needs to reflect both the cost of materials and how often those prices change.

- Travel and transit - Fuel, truck maintenance, tolls, and windshield time matter. For multi-stop days, or wide service areas, these costs eat into margins if not included upfront in your HVAC pricing.

- Tool and equipment wear - Ladders, vac pumps, recovery machines—none of it lasts forever. Each job adds wear and tear. Baked-in equipment usage costs help you keep replacement and maintenance budgets on track.

- Urgent response fees - Emergency calls during off-hours or peak weather seasons should cost more. Customers expect to pay extra when they need fast service. Pricing models should account for this demand.

- Hidden time sinks - Jobs that seem simple can turn sideways—wrong system spec, clogged lines, or damaged ductwork. Including a buffer for surprises gives you flexibility without compromising your quote.

- Overhead - Think insurance, office payroll, phones, uniforms, CRM tools, or platforms like HVAC field service management software—they don’t show up on the invoice, but they have to be paid for. Overhead is where many shops shortchange themselves.

- Regulatory and tax expenses - Permit fees, environmental compliance (like proper refrigerant handling), and local taxes all shape final pricing.

By tracking these buckets carefully, your estimates won’t just cover your bases—they’ll help you stay competitive while protecting your bottom line. Pricing HVAC jobs well takes more than a guess—it takes a system. Next, we’ll walk through the step-by-step process that top HVAC shops use to build pricing that works in real-world conditions.

The commercial HVAC growth report

Find out how commercial HVAC companies excel and grow their business.

How to price HVAC jobs for optimal returns

A good HVAC pricing model isn’t something you guess your way through. It’s built on real numbers, smart research, and a clear plan. Whether you're doing installs, service contracts, or same-day repairs, you need a process to make sure your pricing makes sense—and actually makes money. Here’s a six-step approach contractors use to lock in dependable HVAC service pricing:

1. Figure out your baseline costs

Start with the numbers you can’t ignore—labor, fuel, tools, overhead, taxes. Every dollar that leaves your business should be accounted for when you’re estimating for HVAC work. If you’re not sure where to begin, tools like HVAC estimating software can help simplify cost tracking and quote building.

2. Check your local market

What are other contractors in your area charging for the same types of work? What do your customers expect to pay? Whether it’s a full install or a seasonal tune-up, your pricing needs to line up with demand and competition. This is where HVAC pricing strategy shifts from internal to external—what works on paper needs to hold up in the field.

3. Pick a model that fits the job

Flat rate, time and materials, tiered packages—each project might need a different approach. For recurring jobs like maintenance plans, consider tools like HVAC quoting software to speed up and standardize your estimates. The goal is to stay profitable while making pricing easy for the customer to understand.

4. Build quotes based on job-specific info

Don’t guess—scope the site, check equipment specs, calculate time and labor, and understand what the customer really needs. If you’re handling a multi-location commercial account or a one-off residential fix, HVAC invoice templates can help you lay out line items clearly.

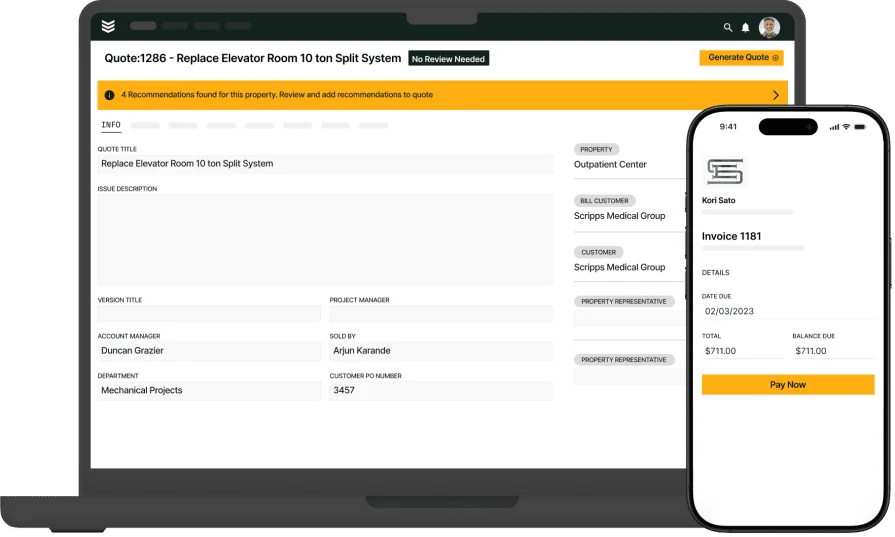

5. Send invoices fast—don’t wait

Once the job’s wrapped, invoice immediately. Delays often mean slower payments. Using invoice automation software can get your invoice out the door faster and even collect payment on-site. Less paperwork, faster cash flow.

6. Review your field reports and adjust

Every job is a chance to refine your pricing. Use field service reporting tools to compare estimates vs. actuals. How much time did the job take? Did you underquote on materials? Adjust your HVAC service pricing accordingly. Tracking the details today helps you price smarter tomorrow.

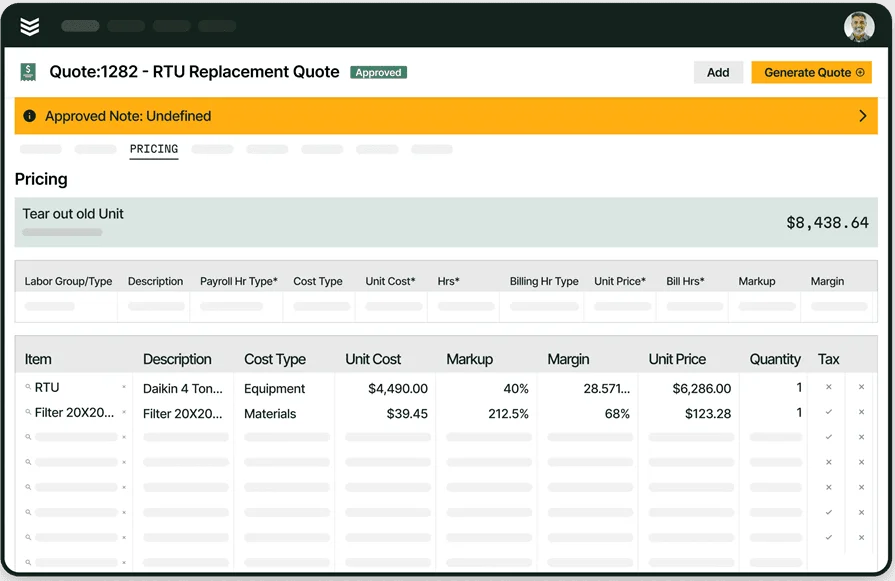

Explore our quoting tool

Precisely estimate jobs to streamline project execution and billing.

Great HVAC pricing is built, not guessed. Each step you take to document, automate, and refine your system makes quoting faster, more accurate, and easier to explain to your customers.

Real-world examples of HVAC pricing in action

Good pricing doesn’t happen in a vacuum. Whether you’re working on a small repair or quoting a multi-zone install, knowing what other contractors charge gives you context—and keeps your numbers competitive. Here’s how HVAC pricing typically plays out in the field:

1. Residential repairs

Quick repair calls are the bread and butter for many HVAC contractors. Jobs like fixing a blower motor, replacing a capacitor, or recharging refrigerant often fall in the $150 to $450 range. What you charge depends on response time, distance to the job site, and system type. For example, servicing a heat pump during winter in tight crawlspaces takes more time—and that time needs to be priced. Factor in your diagnostic time, tool usage, and whether it’s a first-time customer or part of a service plan.

2. Residential maintenance

Homeowners want peace of mind when it comes to their HVAC systems, which makes maintenance visits a great value-add. A single visit may range from $75 to $200, while annual service contracts often sit around $500, depending on how many visits are included.

Pricing here can be influenced by how deep the service goes. A basic check might cover filter swaps and a quick coil rinse. More comprehensive plans include testing capacitors, inspecting duct integrity, and checking thermostat function. Don’t underprice this work—it’s preventive service that keeps systems efficient and builds trust.

3. Commercial repairs

Larger systems mean more at stake. A commercial rooftop unit needing motor replacement or refrigerant repairs will usually cost between $450 and $1,000, not including parts. Commercial clients often expect faster service and cleaner communication.

You’re working around business hours or coordinating with building management, which eats into your day. Repair pricing often overlaps with terms set in a commercial HVAC service agreement, especially when you're handling ongoing contracts or priority response clauses. Make sure pricing reflects added labor, safety protocols for roof access, and any specialty tools required for the job.

4. Commercial maintenance contracts

Service agreements for commercial buildings are a solid source of recurring income. Pricing often ranges from $1,700 to $2,000 per unit, per year, depending on visit frequency, type of equipment, and site location.

These contracts typically include filter changes, belt replacements, system checks, and seasonal tune-ups. For facilities that depend on uptime—like medical centers or server rooms—visit frequency goes up, and so should your rates. Structuring your pricing around commercial HVAC maintenance agreements helps ensure your service covers what building managers actually need and are willing to pay for.

5. System installations

Installation is where margin lives—but it’s also where mistakes cost you the most. Residential installs tend to range from $5,000 to $12,000. Factors that drive cost include equipment brand, SEER rating, ductwork scope, and attic or crawlspace access. Commercial HVAC installs go much higher—$20,000 to $50,000+ depending on the number of zones, complexity of controls, and equipment type.

Pricing HVAC jobs like these should always factor in permit handling, crane or lift rentals, coordination with other trades, and final commissioning. Accurate scoping and a written process for change orders can keep profit from slipping through the cracks.

These examples aren’t just about quoting what the market expects. They’re about understanding what it really takes—time, tools, travel, and tech skill—and making sure your pricing reflects the full picture.

How to avoid underpricing (and losing money) in HVAC

Underpricing happens when quotes don’t reflect the full cost of doing the job. That gap eats into your margins and makes every job feel like a race just to break even. Here’s how HVAC contractors stay profitable without guessing their way through the numbers.

1. Account for every cost tied to the job

Most losses happen because shops miss the smaller details—travel, equipment wear, admin labor, and idle time all add up. If you're only counting parts and labor, you’re shortchanging yourself. Use job data from your HVAC work orders to track what each job actually takes. Factor in overhead—fuel, insurance, licensing, payroll—and roll that into your rates so you’re covering the full picture.

2. Set pricing boundaries that protect your profit

Your team needs clear limits. A pricing floor ensures you’re not taking jobs that leave you with nothing. It also helps your techs and sales reps quote with confidence, knowing there’s a minimum that keeps the business healthy. Keep your HVAC price book current with real labor rates and updated part costs. Add seasonal adjustments and use case-specific pricing so you're not relying on outdated numbers that don’t hold up.

3. Use AI-powered tools to enable billing

In our report The Pivot Point: The Future of Commercial Contracting, 91% of contractors said that bidding is more competitive than ever, and 80% say that adopting AI-powered tools will be essential to staying competitive within the next 3 years.

AI tools can really help with preventing underestimating work by unifying your pricing books, knowing your margins, and bringing in data from past projects.

4. Use competitor pricing as a benchmark, not a template

Looking at what others charge helps you understand the market—but it shouldn't dictate your rates. If your crew works faster, uses better tools, or handles more complex installs, your pricing should reflect that. Track what others are offering, then compare that to your own process, skill level, and service quality. If you deliver stronger results, your HVAC service pricing should show it.

5. Use field data to back up your numbers

Every job holds data you can use to build smarter rates. Job duration, materials used, time on-site—these should all shape your pricing over time. Your HVAC service platform should be logging these metrics automatically. That way, you're not working off guesswork. You’re adjusting based on real patterns—tech efficiency, job types, and average cost per visit.

6. Review your rates regularly

Prices shift fast—fuel jumps, parts go up, wages change. If you’re only reviewing once a year, you’re leaving money on the table. Use quarterly check-ins to make sure your pricing still covers your costs. If you rely on HVAC contract templates, include flexibility to update terms when needed. That way, you’re not locked into outdated rates for long-term service agreements. Smart pricing keeps your business strong. Get paid for the full value of your work—and stop letting avoidable gaps drain your profits.

Wrapping up: pricing with clarity, quoting with confidence

Building strong HVAC pricing isn’t about copying what the shop down the street is charging. It comes from understanding your costs, your value, and what it takes to keep your crew busy without burning out your margins. Whether you're quoting installs, setting up maintenance contracts, or trying to get paid faster for those late-night service calls, your pricing model should work just as hard as your techs do.

That’s where tightening up your invoicing and payment process makes a difference. Tools like digital invoicing and real-time payment solutions help speed up cash flow and reduce the time spent chasing checks. And when everything—from job costing to billing—lives in one system, you're not juggling spreadsheets or bouncing between apps to close out a job.

For HVAC contractors who want one platform that handles pricing, quoting, dispatch, invoicing, and payment collection all in one place, BuildOps brings it all together without the usual hassle.

Curious how BuildOps works?

We help HVAC pros quote cleaner, invoice faster, and keep cash moving.