Keeping jobs on track—from the first call to the final invoice—takes serious coordination. But for many contractors, that coordination still runs on sticky notes, whiteboards, and “Did you see my text?” messages. It’s a setup that leads to missed tasks, backlogged jobs, and unpaid work.

Work order software brings order to the mess. It gives contractors one place to manage job details, track field progress, and keep billing clean. Field service management as a whole has pushed contractors to rethink how work gets assigned, completed, and tracked—especially as jobs get faster and expectations climb.

Here’s what we’ll cover:

- How to choose the right work order software for contractors

- 6 key features to look for in contractor work order management software

- 8 best work order software for contractors

- 7 benefits of using work order management software for contractors

- 4 important FAQs about work order software for contractors answered

Every crew runs a little differently. Some juggle emergency calls all day. Others focus on planned maintenance or big install jobs. Choosing work order software for contractors is about finding one that fits how your team works in the real world. Let’s break down what to look for before you commit.

How to choose the right work order software for contractors

Whether you're managing a lean operation or juggling a dozen crews across town, work order software for contractors needs to support the real-world mess—without slowing your team down. Start by asking these five sets of questions that will cut through the noise and help you find the right fit:

- Workload and Team Size – Are we managing enough jobs to make software worth it? Will this scale if we add trucks, techs, or new service areas? Do we need to support both on-demand work and recurring tasks?

- Field Accessibility – Can techs pull up work orders from the field without calling the office? Do they have mobile access to notes, photos, and job history? Will updates from the field sync in real time with the office?

- Job Coordination – How are we currently handling dispatch and scheduling? Are work orders getting delayed because we’re relying on manual tools? Do techs and office staff have a shared view of the job queue?

- Customer Experience – Are clients chasing us down for updates or asking for copies of invoices? Can we track and respond to follow-up requests or issues easily? Will this platform help us look more organized and responsive?

- Features – Does the software cover core needs like job tracking, time logs, and asset history? Can it handle recurring work orders, emergency scheduling, and digital signatures? Will it replace multiple tools we’re currently juggling (scheduling, notes, invoicing)?

Once these bases are covered, that’s when contractor work order software shows its real value—connecting the dots between what’s happening in the field and what needs to happen next. Let’s take a closer look at the must-have features that power that connection.

6 key features to look for in contractor work order management software

Work orders drive every job your team touches. From scheduling to invoicing, each one needs to move fast and stay accurate. That’s why work order software for contractors has to do more than store job info—it needs to keep the entire workflow connected, from the office to the field. Here are six features that make that happen:

1. Service agreement tracking

Tying recurring jobs directly to work orders is a must if you handle routine maintenance or long-term contracts. With service agreement management, your system automatically generates and schedules new work orders based on the contract terms. Say your team handles bi-monthly pump inspections at several industrial sites. Rather than manually creating a new ticket each time, the software builds those work orders in advance—matching the timeline, crew, and location—so nothing falls through the cracks.

2. Scheduling and dispatch tools

To keep work orders moving, you need real-time visibility across the board. Field service scheduling and dispatch software helps assign jobs based on availability, skillset, and geography—all tied back to the work order itself. Let’s say a pipe burst and your dispatcher needs to reroute a crew immediately. They drag and drop the job on the schedule, triggering a new work order with updated location and task info. The assigned tech gets it on their phone before they’ve even left the previous site.

3. Mobile access for technicians

Techs need more than a clipboard. With a technician mobile app, every work order goes straight to their device—complete with notes, checklists, photos, and updates. Imagine your tech is on-site and needs to confirm what was done during the last visit. They open the work order, see the full service history, and avoid redoing something that’s already been handled. That’s time saved, and no more “I’ll call the office and get back to you.”

4. Time tracking and labor logs

Accurate time logs tied to work orders mean better payroll, cleaner job costing, and fewer admin headaches. Time tracking tools let your crew log hours directly against the job as it happens. Say, for example, your crew might run five work orders in one day. With mobile time tracking, each job gets tagged with start/stop times—no scribbled notes, no forgotten entries. That data goes straight into the work order record and shows up in your reports automatically.

5. Quoting and invoicing tools

The faster you close the loop on a work order, the faster you get paid. Quoting and invoicing tools let you turn finished work into dollars without switching between systems. Picture that when replacing a failed unit, your tech adds materials and labor to the work order in the field. The system builds an invoice using the logged data and sends it to the customer right away. No delay, no double entry, and no missed charges.

6. Job history and reporting

Tracking job performance over time starts with the work order. With reporting features, you can analyze which jobs take the longest, which customers call back, and how each crew is performing. For example, say one type of repair keeps popping up across sites. You pull a report on every related work order over the past quarter, spot the pattern, and decide to replace those units proactively. Fewer emergency calls, less rework, and smarter planning moving forward.

Supercharge service management

Explore our service management suite and see how we empower contractors.

Other notable contractor work order software features

Beyond the core tools, there are other features that help field service teams manage work orders more efficiently. These added capabilities give contractors stronger visibility, better coordination, and smoother job execution—especially when multiple teams or assets are in play.

- Fleet tracking and equipment oversight - When managing service calls across multiple job sites, having eyes on your fleet adds serious value. With fleet tracking tools, you get real-time location data for every vehicle, helping dispatchers assign work orders based on proximity. This leads to faster response times, fewer delays, and better fuel use—all while keeping your work order scheduling sharp and efficient.

- Customer and lead management integration - Work orders don’t exist in a vacuum—they start with a request. With built-in CRM tools, your team can track customer history, upcoming jobs, and even sales opportunities—all connected to the work order record. This keeps communication tight, ensures nothing gets missed during handoffs, and gives office staff full visibility from first call to final invoice.

- Sales pipeline visibility - In many contracting businesses, quoting jobs and booking them into the calendar happens fast. That’s where a connected sales pipeline system helps. It shows what jobs are pending, what’s been approved, and what still needs to be scheduled—giving your team the insight to turn estimates into active work orders without delay or confusion.

With the right features in place, work order software for contractors becomes the backbone of your daily operation. But not every platform brings the same value to the table. Let’s take a look at the top tools out there—and how they stack up for field service teams managing complex work orders.

8 best work order software for contractors

There’s no shortage of software out there that promises to simplify job tracking and dispatch. But when it comes to managing service calls, technician schedules, and job history all from one place, only a few tools really understand the pace of field work. Work order software for contractors needs to move fast, stay accurate, and keep both the field and office in sync without the constant back-and-forth.

We’ve rounded up eight work order solutions that stand out for their strengths in field service management, job coordination, and reporting. Each one solves a piece of the puzzle—but some may be better suited for specific types of contractors than others.

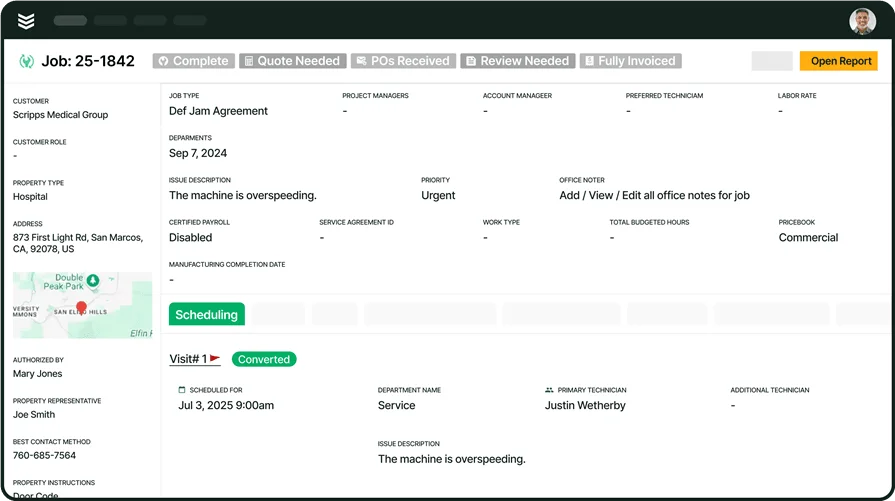

1. Best for commercial contractors: BuildOps

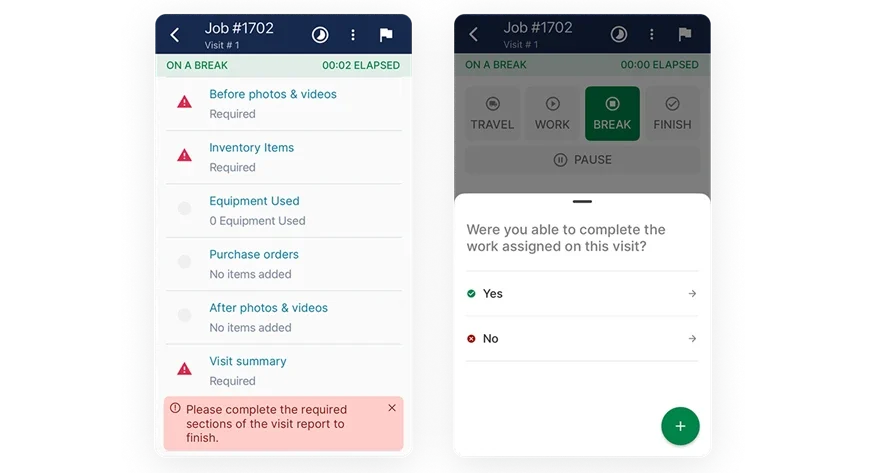

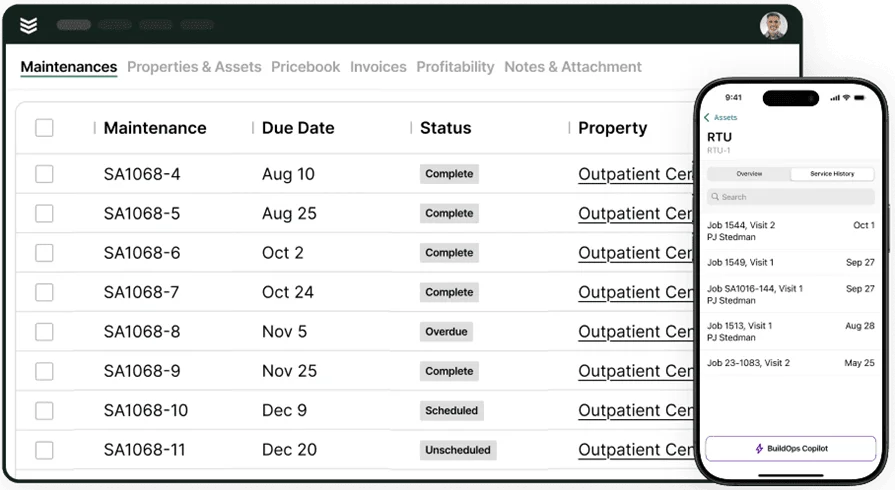

BuildOps is an all-in-one solution purpose-built for commercial contractors. It centralizes work order management, scheduling, dispatch, reporting, quoting, and field communication—everything synced across office and field teams. The platform supports asset tracking, real-time dispatching, AI-powered notes, and a mobile app so techs can view, update, and close work orders from anywhere.

How Pricing Works: BuildOps uses a custom pricing model based on company size, number of users, and feature needs.

What Sets It Apart: Native customer hierarchy support, real-time job tracking, and powerful reporting built for field-heavy workflows

Key Features:

- Smart scheduling and dispatch

- Centralized work order tracking across all teams

- Technician mobile access with job checklists and time logs

Give BuildOps a Try

We help contractors manage jobs faster, more accurately, and without hassle.

2. Best for residential contractors: Fiix

Image Source: Fiix

Fiix is a CMMS platform designed to help residential contractors streamline preventive maintenance and asset management through digital work orders. It supports mobile access, recurring job scheduling, and custom workflows for managing job requests and approvals. Fiix is strong for residential maintenance teams but may feel limited for contractors handling multi-crew service work or commercial-scale operations.

How Pricing Works: Tiered plans based on features and user count

What Sets It Apart: Maintenance-focused interface and built-in asset tracking

Key Features:

- Preventive maintenance scheduling

- Mobile work order creation and completion

- Integration with parts inventory and asset records

3. Best for general contractors: Fieldpoint

Image Source: Fieldpoint

Fieldpoint offers a modular work order management system aimed at general contractors and project-based service providers. It includes project management tools, scheduling, quoting, and integrations with ERPs like QuickBooks and NetSuite. It can be powerful for multi-service firms but may involve a steeper learning curve for smaller contractor teams or those needing fast onboarding.

How Pricing Works: Enterprise-level pricing upon request

What Sets It Apart: ERP integration and industry-specific modules

Key Features:

- Work order templates for different job types

- Job costing and project billing tools

- Asset and contract linking for repeat jobs

4. Best for small teams: FMX

Image Source: FMX

FMX focuses on simplicity, offering a clean, user-friendly work order software ideal for smaller field teams. It supports request submissions, job tracking, technician assignments, and email notifications without overwhelming the user. FMX is great for lean teams, but may lack deeper customization and reporting options needed by larger or multi-location contractors.

How Pricing Works: Subscription pricing by user count and add-ons

What Sets It Apart: Simple interface with fast setup and minimal training required

Key Features:

- Centralized job request portal

- Work order lifecycle tracking

- Calendar-based scheduling

5. Best for fast-growing service teams: Limble CMMS

Image Source: Limble CMMS

Limble CMMS is a modern maintenance platform with strong mobile functionality and fast deployment. Its user-friendly interface makes it easy for field techs to create, track, and complete work orders, while managers can view asset performance and labor data in real time. While ideal for growing teams, Limble may not offer the complex scheduling or field-level customization larger contractors require.

How Pricing Works: Tiered subscription pricing based on user type and features

What Sets It Apart: Clean UI, fast setup, and real-time asset visibility

Key Features:

- Work order automation and priority filters

- Technician performance tracking

- Custom fields and form templates

6. Best for enterprise service operations: PTC

Image Source: PTC

PTC’s work order management tools focus on enterprise-scale field service operations. It provides advanced service lifecycle management capabilities, including warranty validation, asset traceability, and predictive service recommendations—well-suited for manufacturers and large commercial contractors. However, it may be overly complex for mid-sized teams looking for quick deployment and intuitive interfaces.

How Pricing Works: Custom enterprise pricing

What Sets It Apart: Deep integration with engineering and asset data

Key Features:

- Full asset and warranty lifecycle support

- AI-based service recommendations

- Complex job routing logic

7. Best for mobile-first teams: UpKeep

Image Source: Upkeep

UpKeep is a mobile-first work order software tool designed for field teams that prioritize speed and flexibility. It lets users create, assign, and close work orders directly from a phone, while syncing data with dashboards that track labor, asset status, and job completion rates. It works well for mobile crews, but may not offer the broader job costing and scheduling tools required for commercial contractor workflows.

How Pricing Works: Per-user pricing based on feature tier

What Sets It Apart: Mobile-first interface and fast field communication

Key Features:

- Work order updates from mobile devices

- Real-time team messaging

- Maintenance history by asset

8. Best for data-driven teams: Hexagon

Image Source: Hexagon

Hexagon’s field service work order tools are built with advanced analytics and GIS capabilities, helping contractors optimize routing, track real-time performance, and drill into job-level KPIs. This makes it especially strong for utility providers and contractors working across large geographic areas. That said, the platform’s complexity and data-first setup may not suit contractors who need quick scheduling or fast setup.

How Pricing Works: Enterprise quote model

What Sets It Apart: Built-in mapping tools and location-based insights

Key Features:

- Geolocation for scheduling and dispatch

- Work order KPI dashboards

- Asset tracking by site or region

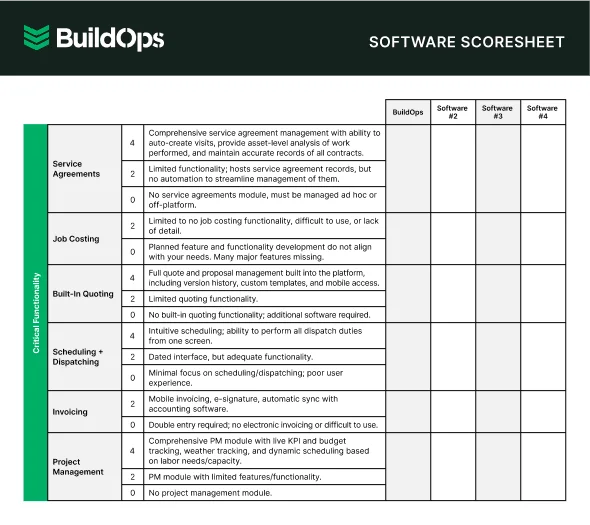

Compare tools at a glance

Find the ideal software for you with our easy-to-use comparison scoresheet.

7 benefits of using work order management software for contractors

Every lost work order, delayed update, or double-booked crew cuts into profit. Contractors in the field need tools that not only track jobs—but actually help close them out faster, cleaner, and with fewer mistakes. Work order software for contractors does just that by connecting the dots between the crew, the customer, and the back office—all in real time. Here’s what it helps you do:

1. Faster job closeouts and fewer delays

With job info, checklists, and approvals all linked to a single system, work orders get closed faster. Field teams don’t have to call for updates or wait for someone to approve the next step—everything’s ready when they are. A smart field service ticketing system helps reduce delays by keeping job tickets organized and accessible through the full job lifecycle.

2. Clearer insights from every job

Contractors need to see what’s working—not just guess. With data tied to every work order, you can monitor average job durations, spot bottlenecks, and adjust based on real performance. Using field service reporting helps teams understand what’s slowing them down and where time is actually spent on-site.

3. Smarter decisions with field-driven data

Data doesn’t help unless it’s easy to understand. With analytics built into your work order software, contractors can identify patterns in job types, service frequency, and technician output—turning raw job data into actionable insight. Field service analytics supports this by showing trends that help guide staffing, quoting, and dispatching decisions.

4. Real-time visibility across all crews

Work order software gives dispatchers and managers a live view of jobs in progress. Whether it’s checking the status of a repair or verifying a signature was captured, real-time access to every job keeps teams aligned. Field service dashboards make this even easier by showing all jobs, techs, and statuses on one screen.

5. Stronger customer follow-through

Every completed work order is a chance to win trust or lose it. Automated follow-ups, invoice delivery, and easy-to-read summaries help close the loop with customers faster. It also makes rebooking and quoting the next job easier because everything’s already logged.

6. Less back-and-forth between teams

When everything is in one system, techs aren’t chasing down dispatch for updates, and the office isn’t stuck re-entering job notes. Work order updates, photos, signatures, and time logs are all synced—cutting down the miscommunication that causes delays and rework.

7. Better accountability across jobs

With digital time stamps, photo logs, and activity tracking, it’s clear who did what—and when. That makes it easier to spot missed steps, review quality, and settle disputes without guesswork. Contractors can keep tighter control over every job with full visibility into how work orders are executed in the field.

4 important FAQs about work order software for contractors answered

If you’re considering work order software for contractors, you’ve probably got a few questions—about what it does, who needs it, what it costs, and how to get it running smoothly. Here are four of the most important ones we hear from field service pros.

1. What is work order software?

Work order software is a digital tool that helps field service contractors create, assign, track, and close out job tasks—all in one place. It replaces manual processes like whiteboards, spreadsheets, or paper tickets with a single, centralized system. It keeps both the field and office aligned.

With the right platform, contractors can streamline how they dispatch teams, track labor, collect signatures, and log materials. This ensures smoother operations and more accurate record-keeping for every job.

2. How much does work order software cost?

Pricing depends on the features, users, and scale of your operation. Here’s how most software pricing tiers break down for field service businesses managing work orders:

- Starter Plans ($20–$50 per user/month): Great for small crews or solo contractors. Includes basic work order tracking, scheduling, and mobile access.

- Professional Plans ($50–$150 per user/month): Adds features like quoting, asset tracking, invoicing, and CRM. Best for growing teams with office and field coordination needs.

- Enterprise Plans (Custom pricing): Built for large contractors managing multiple teams, properties, or service divisions. Includes custom workflows, integrations, and advanced reporting.

3. Who needs to use work order software?

Work order software helps contractors take control of scheduling, task tracking, and field-to-office coordination. It’s especially useful for service-based teams working across job sites with crews in the field. If you rely on consistency, fast updates, and accurate job completion, this tool keeps everything moving.

You’ll benefit from using work order software if:

- You manage multiple jobs per day and need a dependable way to assign, update, and close work orders in real time

- Your technicians depend on calls or texts for job details, leading to missed tasks or confusion

- Your team enters job data in separate systems, causing delays, duplication, or errors

- You run recurring service calls and need a way to tie each visit to a contract or asset

- You need clear job history and accountability for labor hours, materials, and field notes—all tracked by job

It’s built to support contractors who need speed, structure, and visibility on every job.

4. What are the best practices for using work order software?

Rolling out new software takes more than logging in—it takes alignment across your whole team. Here’s how to get the most value from it:

- Assign a project lead to manage the rollout internally

- Start with core workflows like dispatch, work order creation, and invoicing

- Involve both techs and office staff early in the setup

- Clean up old customer/job data before importing

- Use templates and checklists to standardize work order creation

- Train your team with hands-on sessions, not just videos

- Track KPIs like job closeout time, completion rate, and missed steps

- Schedule regular check-ins to adjust your setup based on real feedback

In the field, things change fast. One job runs long, another gets added, and suddenly your whole day’s off track. That’s where work order software earns its keep—not by adding complexity, but by cutting through it. It keeps everyone—from the office to the jobsite—on the same page, with less chasing, fewer missed steps, and more jobs done right the first time.

For contractors handling high-volume commercial work, the pressure’s even higher. That’s when having an all-in-one platform like BuildOps isn’t a nice-to-have—it’s how you keep your operation moving without burning out your team.

Thinking about switching?

See how BuildOps helps contractors orchestrate crews and manage workflows.