Fire Suppression Systems provide an efficient way of inhibiting the spread of flames, smoke, and soot in the event of a fire. These systems are designed to contain, suppress, or extinguish fires with the use of different methods, including water, flame retardants, or dry chemical agents.

The most common type of fire suppression system consists of a network of pipes connected to a series of sprinkler heads. The pipes contain pressurized water or other fire suppressants, and the sprinklers will activate automatically when temperatures reach a preset threshold in certain areas. Sprinkler systems are often used for large buildings, warehouses, and industrial areas due to their fast response time and wide coverage.

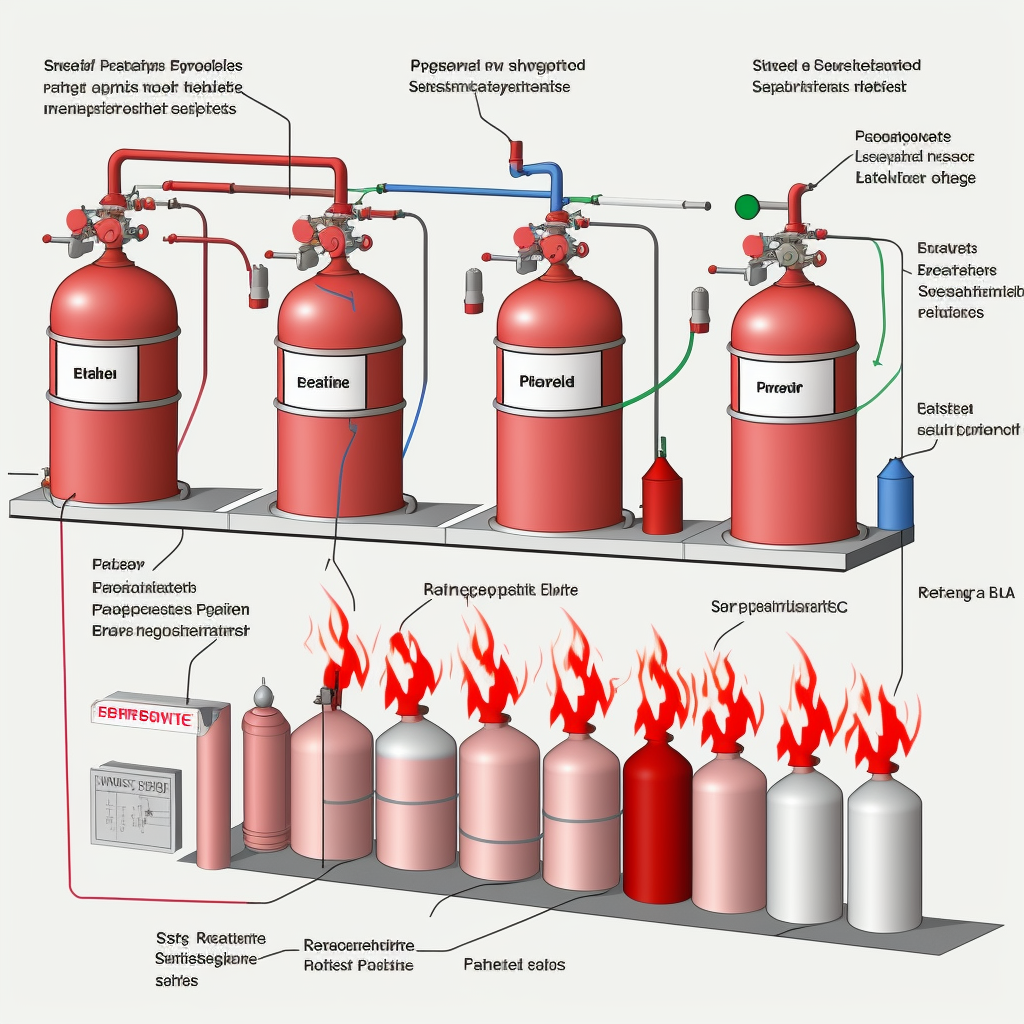

Gaseous systems use a variety of inert gases with different characteristics to extinguish and suppress fires. Gaseous suppressants such as carbon dioxide, nitrogen, argon, and halons extinguish flames without the need for water, making them a great choice for certain electronic components, computer server rooms, and other fire-sensitive areas.

Another type of fire suppression system is the foam suppressant system, which creates a blanket of foam over the fire to prevent further spread of heat and minimize damage to the area. Foam suppressants are often used for aircraft hangars, gas stations, and other areas where oil, gasoline, or other combustible liquid is distributed.

For more hazardous materials, water and foam suppressants are often combined with dry chemical agents. Fire-extinguishing agents like potassium bicarbonate, mono ammonium phosphate, or sodium bicarbonate are released to create a protective layer on top of the fire, preventing oxygen from reaching the flame.

Finally, a mobile fire suppression system can also be utilized in certain areas. These fire suppression systems can be set up quickly and require no permanent installation. They come in various forms, including fire extinguishers or portable fire suppression units, which can be deployed quickly to effectively combat fires and protect property.

What are the benefits of using fire suppression systems?

Fire suppression systems offer a variety of benefits, including improved safety, cost savings, and increased efficiency. By providing an efficient way to contain and extinguish flames, these systems reduce the amount of damage and destruction caused by fire outbreaks.

One of the key advantages of using fire suppression systems is improved safety. They are designed to respond quickly to contain and suppress fires, minimizing the risk of injury to property and personnel. Fire suppression systems are also very reliable, capable of working as intended even in the most extreme conditions.

In addition, fire suppression systems can lead to cost savings over time. They require minimal maintenance and help to prevent losses from fire damage, thus reducing the need for expensive repairs or replacements of damaged property.

Fire suppression systems also help to increase efficiency and productivity across the workplace. By allowing areas to be quickly returned to a safe, operational state, they reduce slowdowns and delays caused by fire outbreaks.

Overall, fire suppression systems provide a number of advantages, helping to ensure the safety of property and personnel while minimizing the potential for losses from fire damage. They are reliable, cost-effective, and efficient, making them a great choice for businesses of all sizes.

What are the differences between water, foam, and dry chemical fire suppression systems?

Water, foam, and dry chemical fire suppression systems are all used to contain and extinguish fires, but they differ in terms of how they work.

Water suppression systems are the most common type, consisting of a network of pipes connected to a series of sprinkler heads. When the temperature reaches a preset threshold in certain areas, the sprinklers will activate automatically and release pressurized water to suppress or extinguish flames.

Foam suppression systems use a combination of foam and water to create a blanket of foam that blocks off the oxygen supply to the flames. The foam effectively prevents further spread of heat and minimizes damage to the area, making it great for fire-sensitive areas such as aircraft hangars and gas stations.

Dry chemical fire suppression systems utilize different fire-suppressing agents such as potassium bicarbonate, mono ammonium phosphate, or sodium bicarbonate to create a protective layer on top of the fire in order to prevent the spread of flames. These systems are often used in hazardous areas, such as chemical or oil storage facilities.

Overall, the different types of fire suppression systems all serve the same functional purpose, but they differ in terms of their usage and effectiveness. Water systems are best for large buildings and industrial areas, while foam suppressants are ideal for aircraft hangars, gas stations, and other areas with flammable liquids. Dry chemical suppressants are the most efficient for hazardous and flammable materials, such as fuel or chemical storage facilities.

What components are necessary for a fire suppression system to work?

A fire suppression system is made up of several components, which vary depending on the type of system being used. Generally speaking, all systems require a network of pipes connected to a series of sprinkler heads or nozzles that contain pressurized water or other fire suppressants. These are usually triggered when temperatures reach a certain threshold in certain areas and their activation can be controlled either manually or automatically.

In addition to the pipes and nozzles, most fire suppression systems also need an alarm system so that personnel can be warned about any potential fires. In addition, they may include sensors and detectors that measure the temperature and detect smoke in order to activate the sprinklers more quickly than manual operation would allow. Finally, there needs to be a central control panel to allow regulation of the system, as well as an emergency backup power supply to ensure it continues working even if there is a failure in the main power grid.

Overall, these components are necessary for a fire suppression system to function properly and quickly contain and extinguish fires in order to minimize damage and loss. By ensuring that all critical components are present and functioning correctly, businesses can ensure their premises remain safe from potential fires.

Are there long-term maintenance requirements for fire suppression systems?

Yes, there are certain maintenance requirements for fire suppression systems to ensure that they remain in proper working order and can effectively contain and extinguish fires.

First, regular testing should be conducted to ensure the system is functioning properly. This includes checking all components of the system, including pipes, nozzles, alarms, sensors, and detectors as well as making sure they have been correctly installed. In addition, the manual control valves should be tested regularly to make sure they are functional and responsive.

It is also important to check the pressure on a regular basis to ensure it has not dropped below an acceptable level. Finally, any parts or components that show signs of damage or wear should be replaced immediately to avoid potential malfunctions.

Overall, fire suppression systems require regular maintenance in order to ensure they are able to effectively contain and extinguish fires. By taking the necessary steps to keep them well-maintained, businesses can ensure that their premises remain safe from potential fires.

What types of fires can water-based fire suppression systems extinguish?

Water-based fire suppression systems are effective at suppressing and extinguishing fires caused by many different types of combustible materials. This includes paper, wood, cloth, plastics, and rubber products. In addition, they can also be effective against fires caused by flammable liquids such as gasoline and petroleum.

However, water-based fire suppression systems may not be effective for all types of fires. For instance, they may not be able to effectively contain or extinguish fires caused by metals such as magnesium or titanium due to their high melting point. Similarly, it may not work on electrical equipment or other electronics that have high currents running through them since the water could cause a short circuit resulting in further damage.

Overall, water-based fire suppression systems are effective against many fires caused by combustible materials such as wood, paper, plastics and rubber. However, they may not be suitable for all types of fires and could potentially cause further damage in some cases. It is important to assess the type of fire before selecting a particular suppression system in order to ensure it is appropriate and will work effectively.

It’s also important to keep an eye on any changes that occur in the area where the fire suppression system has been installed. This can include changes in temperature, humidity levels, or other environmental factors that could potentially impact the effectiveness of the system. Additionally, any equipment that has been connected to the system should be regularly inspected for potential malfunctions or wear and tear.

How effective are foam suppressants for large fires?

Foam suppressants are very effective for large fires as they create a blanket of foam that smothers the fire, preventing oxygen from reaching it. This reduces the temperature and helps to contain and extinguish the flames quicker than other types of fire suppression systems.

In addition, foam suppressants can also be used in combination with water-based fire suppression systems to provide additional protection against fires caused by flammable liquids such as gasoline or petroleum. The foam acts like an absorbent material that soaks up the liquid fuel and prevents it from spreading further, thus allowing the water-based system to work more effectively.

Overall, foam suppressants are very effective at containing and extinguishing large fires quickly and efficiently. They can also be used in combination with other fire suppression systems to provide additional protection against certain types of fires, such as those caused by flammable liquids. By using the appropriate suppression system for the job, businesses can ensure that their premises remain safe from potential fires.

What safety measures should be taken for dry chemical fire suppression systems?

When using a dry chemical fire suppression system, it is important to take certain safety measures in order to ensure that the system is used correctly and safely. First, any personnel in the area should be trained on how to properly operate the system. This includes knowing when and how to activate the system as well as understanding any special instructions related to its use.

In addition, personnel should also wear personal protective equipment (PPE) including eye protection, gloves, and respiratory protection when operating or servicing the system. Lastly, regular maintenance of the system should be performed in order to ensure it is functioning properly and can effectively suppress fires.

Overall, by taking these safety measures businesses can ensure that their dry chemical fire suppression systems are used correctly and safely. This will help them to protect their premises from potential fires while also protecting personnel from any potential hazards associated with the system.