Getting your numbers wrong on a bid can sink the whole job before the first wire gets pulled. For electrical contractors juggling shifting material prices, labor pressure, and compressed timelines, a dependable approach to electrical estimating isn’t a luxury—it’s survival. Whether you're quoting a panel upgrade or a full-scale buildout, every detail in your estimate shapes the bottom line. This guide lays out a practical roadmap tailored to the realities of field work and jobsite demands.

Built for those working deep in the electrical industry, this breakdown covers the methods, tools, and templates that help contractors build rock-solid estimates from day one. When estimating electrical work, accuracy isn’t just about winning jobs—it’s about protecting your margin and keeping chaos off the site.

Here’s what you’ll find inside:

- What is electrical estimating?

- 8 steps in the electrical cost estimating process

- 10 essential components of an electrical estimate

- How to estimate electrical costs effectively

- Top 7 electrical estimating templates for you to use

- Top 3 electrical estimating software for costing jobs and projects

Getting electrical estimating right sets the tone for the entire job. Before diving into steps, templates, or tools, it’s important to understand what electrical estimating really involves—and why it matters on every project, big or small.

What is electrical estimating?

Electrical estimating is the process of calculating the total costs required to complete a project—factoring in materials, labor, equipment, permits, overhead, and other job-specific conditions. It gives a detailed breakdown of expenses before work begins, helping ensure the job is profitable and deliverable.

It’s not just about crunching numbers—it’s how electricians win bids, avoid rework, and keep jobs on track. A strong electrical estimate sets expectations for both the crew and the client, helping everyone stay aligned once boots hit the ground. Whether it's a service call or a full system install, estimating electrical work accurately keeps projects moving and margins protected.

8 steps in the electrical cost estimating process

Electrical estimating doesn’t stand alone—it’s one piece of a larger system that keeps the job moving from bid to closeout. For electrical contractors, building out a solid electrical estimate is a critical phase in the field service management process. From scheduling and dispatch to invoicing and reporting, each part of the workflow depends on numbers that are clear and reliable. This step-by-step breakdown shows how to build those numbers with accuracy and purpose.

- Review the project scope - Start by understanding exactly what’s being asked for. Dig through the plans, specs, and notes. Identify service requirements, material types, timelines, and jobsite conditions. No detail is too small—what’s missed here will show up later as rework or cost overrun.

- Perform a site visit (if possible) - Walk the space. Measure, photograph, and flag any install complications—tight access, overhead clearances, or existing systems. Site conditions drive labor time, safety needs, and material logistics. What looks simple on paper often plays out differently in the field.

- Create a material takeoff - List every piece of equipment, fixture, wire, conduit, and fitting needed for the job. Break it out by system—lighting, power, fire alarm, controls. Group by room or zone if needed. This takeoff feeds the rest of the estimate, so accuracy here matters.

- Estimate labor hours by task - Use labor units or crew experience to build time estimates. Match the crew size and skill to the work—rough-in, trim, terminations, gear installs. Don’t forget mobilization, cleanup, or coordination time. Then apply local wage rates or company labor costs to get totals.

- Apply unit costs and pricing - Use current supplier pricing or standard cost books to attach a dollar value to each item on your takeoff. Factor in lead times and availability. Apply markups if needed for profit, overhead, or risk.

- Account for indirect costs and contingencies - Add line items for permits, inspection fees, equipment rental, consumables, supervision, insurance, and bonding. Consider allowances for change orders, delays, or missed scope. A padded line here can protect your margin later.

- Build and format your estimate - Organize all the data into a clear, professional format. Break it down by system, phase, or area—whatever makes sense for the client. Label quantities, unit prices, labor hours, and subtotals. Include exclusions and clarifications to set clear boundaries.

- Review and finalize - Cross-check totals, compare against past jobs, and have another estimator or PM review the numbers. Validate assumptions, and confirm your numbers reflect the true effort needed to deliver. Once it’s locked, it’s your roadmap.

A solid electrical cost estimating process gives you more than a number—it gives you control. These eight steps keep the guesswork out and the profits in. When estimating electrical work with this level of clarity, you’re not just chasing bids—you’re building jobs that make sense from start to finish.

Streamline your operations

Get electrical service work processes, real-life examples, and templates.

10 essential components of an electrical estimate

Every solid electrical estimate includes a core set of components that shape the bid’s accuracy, clarity, and strength. Missing even one of these details can lead to confusion, underpricing, or change order battles down the road. These elements give contractors, project managers, and clients the full picture before a single box is installed.

- Customer information - Name, contact, address, billing info—basic, but critical. Without clear customer details, the estimate floats with no anchor. It’s also your first step toward setting expectations and logging documentation for invoicing and job tracking.

- Project scope and description - This outlines what’s included in the job—panel installs, rewiring, conduit runs, lighting upgrades, or service relocations. It sets boundaries, helps avoid scope creep, and aligns your crew and client on what will (and won’t) be done.

- Material takeoff - This is your breakdown of everything needed on the job—cable, devices, breakers, junction boxes, etc. Quantity, specs, and part numbers help avoid errors during procurement and install.

- Labor hours and crew breakdown - How many hours per task? What kind of crew is needed—apprentice, journeyman, master electrician? This is where your labor cost and schedule start to take shape.

- Pricing breakdown by system or phase - Separate costs by lighting, power, fire alarm, etc., or by rough-in, trim, final. This gives visibility to the client and helps your crew plan installs in stages.

- Overhead and markups - Insurance, office labor, bonding, and profit margins. These hidden costs often get ignored—but they’re real, and they hit your bottom line hard if left out.

- Equipment and rentals - Bucket trucks, scissor lifts, trenchers, generators—anything needed beyond standard tools. Including this avoids last-minute rental expenses eating into profit.

- Permits and fees - Inspections, plan checks, utility hook-ups, AHJ paperwork—if your name’s on the permit, these need to be budgeted for up front.

- Exclusions and assumptions - State what’s not included—like patching drywall, furnishing gear, or trenching beyond a set depth. These notes limit liability and help set boundaries when change orders hit.

- Terms and conditions - Payment schedule, change order policy, validity window of the bid, warranty info—these protect your work and give clients a clear roadmap.

Building a complete electrical estimate means hitting every one of these components—no shortcuts. Skipping one might save time up front but almost always costs more later. Now, with advances in AI-powered electrical estimating software, many of these sections can be autofilled using past job data, pricing libraries, and labor history—cutting down on repetitive entry and reducing room for error.

How to estimate electrical costs effectively: 8 strategies for success

Even with experience, estimating electrical costs can slip if your process lacks structure. A job-winning electrical estimate doesn’t come from guesswork—it comes from applying repeatable strategies. These approaches help electrical contractors reduce risk, stay competitive, and build estimates that reflect real-world job conditions. Whether you’re handling a single-phase panel or a multi-story install, the key is using the right tools and mindset at every step.

1. Use digital bidding tools built for electricians

Relying on spreadsheets can slow you down and leave room for errors. A dedicated electrical bidding app simplifies takeoffs, speeds up calculations, and helps you deliver polished bids on time. It keeps all project data in one place and lets you duplicate or adjust past quotes in seconds.

2. Track real costs from past jobs

Historical job data is gold. Compare your old estimates to actual job costs—labor hours, material usage, rental fees, delays. This gives your current estimates a sharper edge and helps avoid repeat mistakes. Estimators who use job history consistently build tighter and safer bids.

3. Break down pricing by system or install type

Don’t lump everything into one number. Break the estimate down by lighting, panels, conduit, or feeders. This makes the estimate easier to explain to clients and easier for your crew to follow on the job. Organized numbers lead to fewer field questions and cleaner installs.

4. Build quotes directly from field-ready tools

Mobile quote tools allow techs to price smaller service jobs on-site—no office delay. A solid electrical quote app can turn walk-throughs into real quotes before you even leave the site. It also cuts back on handoffs between sales and estimating teams.

5. Factor in payment timing and billing processes

Estimating isn’t just about pricing the job—it’s about cash flow too. If you don’t plan for billing stages, deposits, and payment lag, your job gets squeezed mid-stream. The electrical contractor invoicing guide outlines billing methods that tie directly to project phases—keeping money moving as the job progresses.

6. Invest in estimator training for your team

Even experienced electricians benefit from structured estimator training. Learning how to read specs, use cost databases, and adjust for scope creep builds consistency across your team. Resources like electrical estimator training help level up junior staff and refine senior estimators’ accuracy.

7. Stay current with field-tested electrical apps

Keeping up with the best electrical apps helps you speed up calculations, reference codes, and convert site data into accurate estimates. Whether it’s a conduit fill calculator or load estimator, mobile tools make it easier to move from measurement to math without delay.

8. Review with field leaders before submitting

Before the estimate goes out, loop in your project foreman or field supervisor. They’ll catch install hurdles or time traps that don’t show up on paper. Getting buy-in from the crew that’ll install the work gives your numbers a reality check—and usually avoids costly surprises.

Top 7 electrical estimating templates for you to use

Not every estimate needs software—sometimes a clean, ready-to-go template is all it takes to send out a bid quickly. Whether you’re quoting a panel replacement or a service call, using the right electrical estimating template saves time and keeps things consistent. These options give you a structured format to plug in job details, labor, and material costs without starting from scratch.

1. Invoice Simple

Image Source: InvoiceSimple

This one’s perfect when you just need to get the numbers down and out the door. The layout covers labor, materials, and totals—no clutter, no fuss. It’s not built for big jobs, but for service calls or small installs, it gets the job done.

Cost: Free

Why use it: Ideal for electricians quoting simple jobs on the fly, especially when time matters and the paperwork shouldn’t slow you down.

Take a look at the Invoice Simple electrical estimate and see if it fits your flow.

2. Jobber

Image Source: Jobber

Clean design, space for client info, itemized charges, and a spot for your logo. Jobber’s template helps make your estimate look polished, even if you’re pulling it together from the truck.

Cost: Free

Why use it: Great if you want to send estimates that look professional without needing software or design tools.

You can grab the template directly from Jobber’s free resource page.

3. ArcSite

Image Source: Arcsite

ArcSite gives you a template that works well when the job includes visuals or diagrams. It’s built with layout thinking in mind, which makes it handy for estimating system installs tied to floor plans or site drawings.

Cost: Free

Why use it: Best suited for visual thinkers—especially when you’re tying price to layout and need the structure to show it clearly.

You’ll find their electrical form ready for download over on ArcSite’s utility page.

4. Billdu

Image Source: Billdu

Simple interface, no learning curve, and quick exporting. Billdu’s template doesn’t have all the bells and whistles, but that’s part of the charm. Fast to fill out, easy to send, and no account required.

Cost: Free

Why use it: A solid pick for solo contractors who just want something clean and efficient without the headache.

Their downloadable Billdu electrical form is ready to use in seconds.

5. FreshBooks

Image Source: FreshBooks

FreshBooks brings structure to your estimate without overcomplicating it. You can itemize labor, parts, and even taxes. It’s clean enough for clients and clear enough for crews.

Cost: Free

Why use it: Good choice if you want a polished, professional estimate that doesn’t need a full app to function.

Grab a copy from FreshBooks’ template library.

6. Housecall Pro

Image Source: Housecall Pro

Built with techs in mind, Housecall Pro’s estimate template leans toward residential and light commercial jobs. The layout is structured to flow with the work order, which makes handoffs easier between office and field.

Cost: Free

Why use it: Perfect when you want estimates that line up with your job workflow—especially if your techs need something they can reference fast.

You can test-drive their version by checking out the Housecall Pro estimate format, and be sure to check out our comparison of Housecall Pro vs BuildOps here to see which one is the better fit for your team.

7. ServiceTitan

Image Source: ServiceTitan

ServiceTitan’s estimating template is built for scale—designed to handle more complex projects and multi-phase bids. It organizes every piece from labor and material to discounts and notes, making it easier to manage multiple moving parts.

Cost: Free

Why use it: Best for contractors juggling bigger installs or multiple crews who need clear, comprehensive documentation.

Download the template straight from ServiceTitan’s estimator toolkit, and review our comparison of BuildOps vs ServiceTitan here for more info on their features.

Top 3 electrical estimating software for costing jobs and projects

For larger installs or fast-paced bid cycles, templates don’t always cut it. Electrical estimating software brings speed, accuracy, and organization to the process—especially when you're quoting high volumes or managing crews across job sites. These tools don’t just handle numbers; they connect estimating with scheduling, billing, and project execution. Here are three solid options tailored to different types of contractors.

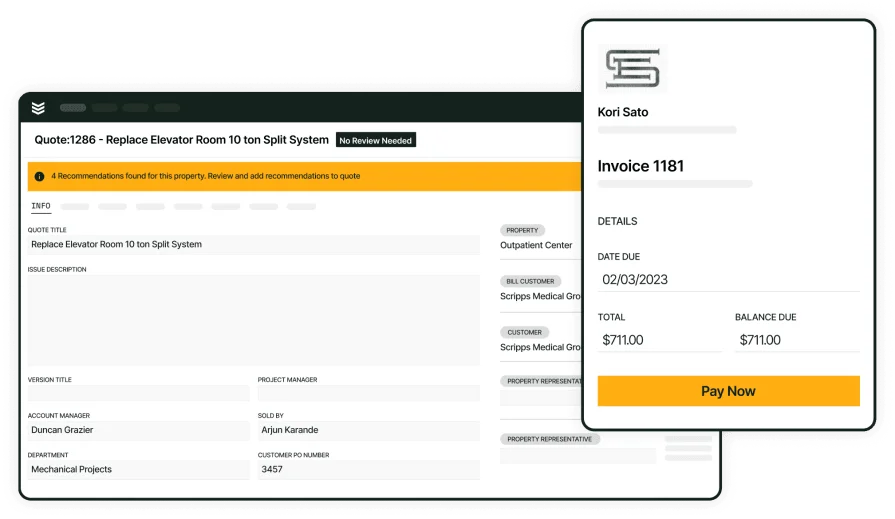

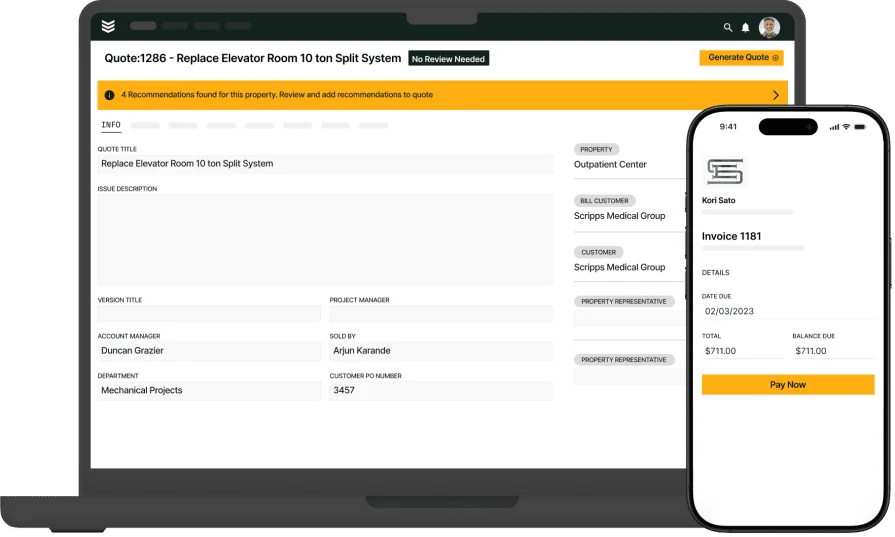

1. Best for commercial: BuildOps

BuildOps has built-in customizable templates you can integrate with other aspects of your field service process, including adding photos and videos to your Quotes, increasing their chances of being approved faster. You can customize fields in BuildOps to fit the most unique aspects of electrical contractor workflows, ensuring it works perfectly for you and your team, rather than using someone else’s estimating templates.

Key features: Estimators can pull labor and material rates directly from field data, convert estimates into proposals in seconds, and hand them off to project managers without losing context. Time tracking, service history, and custom templates are all tied together, giving your team the tools to quote accurately and deliver on time.

What sets it apart: Unlike generic estimating software, BuildOps was made for commercial trades—so it doesn’t stop at quoting. It keeps field teams, back office, and clients aligned throughout the job.

Take a deeper look at BuildOps

We help electrical contractors manage big, fast-moving jobs with precision.

2. Best for residential: Planswift

Image Source: PlanSwift

Planswift is a well-known name in the takeoff and estimating world. It’s a desktop-based tool that lets users pull quantities from PDFs or drawings and then tie them to labor and material databases. It works best for one-off residential projects like service upgrades or remodels. However, Planswift may not be ideal for crews managing ongoing service work or commercial-scale operations—it leans heavily on manual input and doesn't sync with scheduling or dispatch platforms.

Key features: You can drag, drop, and measure items directly off blueprints, build assemblies, and apply pricing from vendor catalogs. It also supports plugins and custom workflows for residential builders.

What sets it apart: Strong visual takeoff features make it ideal for residential contractors quoting jobs from plans.

3. Best for general contractors: McCormick Systems

Image Source: McCormick

McCormick Systems is a legacy player in the electrical estimating space, known for its detailed pricing database and flexible assemblies. It’s often used by estimators who want complete control over unit pricing, labor productivity, and change order tracking. That said, McCormick’s learning curve and interface may be too rigid or outdated for contractors who need faster, mobile-first workflows on active job sites.

Key features: It offers custom labor units, advanced takeoff tools, integration with vendor catalogs, and detailed job costing reports. It’s well-suited for jobs with a long bidding window or heavy spec compliance.

What sets it apart: McCormick excels in customization and is especially useful for larger firms managing multiple job types with strict tracking needs.

Getting electrical estimating right takes more than plugging numbers into a spreadsheet. It’s about bringing accuracy, consistency, and foresight into every bid—so when the work starts, you’re not backpedaling on scope, cost, or labor. From estimating labor hours and tracking field data to building out full-cost breakdowns and issuing clean invoices, every part of the process relies on having the right tools and systems in place.

Most software tools out there check a few boxes—maybe estimating, maybe scheduling—but rarely everything that commercial electrical contractors actually need. That’s where a connected, all-in-one platform makes the difference. With BuildOps, electrical contractors can manage estimating, quoting, dispatch, job costing, and invoicing from one hub—designed specifically for field-heavy commercial work. The features covered in this guide? BuildOps ties them together and then some.

Streamline your project workflows

Estimate projects with precision, saving you costs and speeding up invoicing.