Electrical takeoff software sits at the hinge point between plan markups and field execution. In the electrical service industry, crews bounce between service tickets, retrofit scopes, and small projects where revisions hit mid-bid and supervisors still need clean counts, kits, and labor targets that hold up on-site. Takeoff software for electrical contractors earns its keep when quantities flow into scheduling, dispatch, purchasing, and job costing without re-keying—so estimators, service managers, and techs operate from the same scope.

This guide breaks down what separates the best electrical takeoff software for service-driven electrical teams, including how to pressure-test workflows that support change orders, closeout, and estimate-to-actual review. Here’s what we’ll cover:

- How to choose the right takeoff software for your electrical team

- 5 key features to look for in electrical takeoff software

- 6 best takeoff software for electrical contractors

- 7 benefits of using electrical takeoff software

- 4 important electrical takeoff software FAQs answered

This guide begins with selection criteria that matter in an ops-heavy electrical shop: platform fit, workflow handoffs between estimating and the field, and adoption across supervisors and techs. After that, the list of tools frames trade-offs by service use cases, followed by a feature checklist, practical benefits tied to field execution, and clear answers to common questions.

How to choose the right takeoff software for your electrical team

You already run tight labor targets and fast service schedules. The decision now is choosing electrical takeoff software that keeps quantities, assemblies, and scope changes connected to dispatch, purchasing, and job costing without extra admin. Use this checklist to judge takeoff software for electrical contractors against how your team estimates and executes service work.

- Workflow alignment & integrations: Does it push takeoff outputs into work orders, BOMs, and purchase requests? Does it sync with your field service management, accounting, or ERP stack without constant exports? Do operations leads and techs see the same quantities the estimator approved?

- Electrical assemblies & labor logic: Can you standardize assemblies for devices, conduit, wire, fittings, supports, and terminations? Can you lock labor units by crew type, access conditions, and production rates you trust? Can you tag alternates and options without breaking the baseline scope?

- Accuracy on plan sets: Does it hold scale across PDF sheets, mixed raster scans, and vector drawings? Does symbol recognition catch common electrical callouts without “creative” counts? Does it handle panel schedules, one-lines, homeruns, and circuiting workflows cleanly?

- Revisions, scope control, and audit trail: Does it track addenda and plan versions with clear deltas? Does it surface what changed by area, system, or sheet without manual diff work? Do permissions prevent quantity edits from slipping in after estimate approval?

- Service execution linkage: Do takeoff quantities translate into task lists, pick tickets, and staged materials for techs? Do service managers get visibility into labor targets versus actuals without spreadsheet reconciliation? Do closeout reports tie back to estimate revisions and change orders?

- Software features for field service operations: Does it tie estimate line items to service templates, job types, and task codes used in the field? Does it support scheduling handoffs like crew assignments, skill tags, and planned hours without re-entry? Does it connect materials to purchasing, truck stock, and staged pick lists so techs arrive ready?

The next section breaks down the software features that separate the best electrical takeoff software across estimating, dispatch, purchasing, and closeout.

5 key features to look for in electrical takeoff software

Electrical takeoff software has one job in a service-driven shop: turn plan counts into actions the field can execute, with clean handoffs across scheduling, dispatch, materials, and closeout. For takeoff software for electrical contractors, the proof shows up on chaotic weeks—an add-on panel swap comes in, a tenant improvement scope changes, and a service manager still needs labor targets and staged materials that match what gets installed. The best electrical takeoff software keeps those quantities connected to operations, and electrical estimating takeoff software keeps the feedback loop tight when actuals come back from the field.

1. Scheduling and dispatch connected to quantities

Counts should set planned hours and crew capacity without extra handling. Your platform should route measured assemblies into scheduling and push visits through smart dispatch software in a single workflow, so the day’s board reflects the same scope the estimator approved. In practice, this shows up when a high-priority service call expands into a same-day retrofit: the takeoff updates device counts and labor, dispatch adjusts crew assignments, and the supervisor sees the revised task load before wheels roll.

2. Quote generation from assemblies and counts

Turnoffs to build-ups should translate into customer-ready pricing with labor factors, markups, and alternates locked to the takeoff. Look for takeoff output that converts cleanly inside service quoting software so revisions do not trigger a rebuild from scratch. A common scenario: an estimator finishes a lighting control swap scope, then the customer asks for an additional zone and emergency circuit work—your assemblies update, the quote refreshes with the correct labor and materials, and the service manager can approve the change without chasing a spreadsheet.

3. CRM for bid tracking and handoffs

Precon and service sales live on follow-ups, scope clarity, and clean handoffs. A field service CRM tied to takeoff keeps every opportunity linked to measured scope, alternates, dates, and decision notes, so the handoff to operations includes what matters. You see the value during a multi-site service program: the estimator tags each location’s variations, the account manager tracks approvals, and the dispatcher pulls the approved scope without guessing which revision the customer signed.

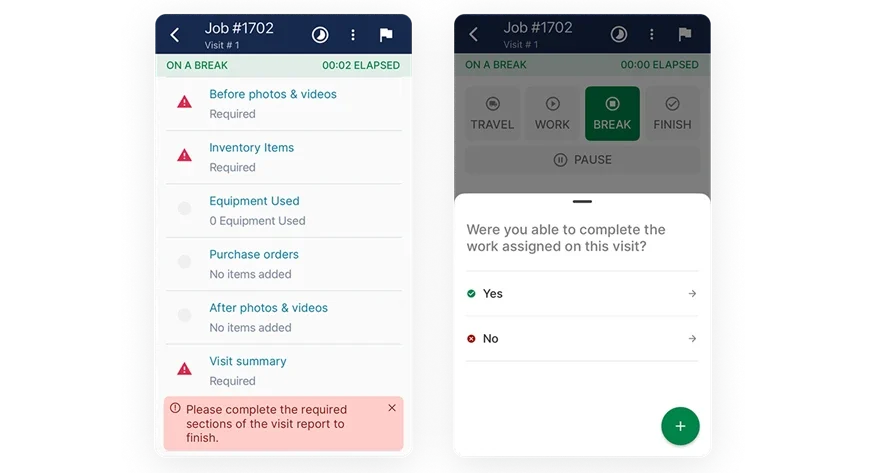

4. Technician mobile app for execution

The field needs what the estimator promised: counts, tasks, and material intent tied to the job. A strong technician mobile app should surface pick lists, task counts, plan snippets, and photos at the work order level, so techs can execute against the takeoff and capture variance in real time. One example: a lead tech arrives to replace a set of disconnects and discovers access constraints that change labor—notes, photos, and status updates flow back to the office, and operations can reconcile scope and time against the original takeoff.

5. Pricing controls and change-order agility

Scope shifts happen fast in electrical service work, so pricing needs controls that stay tied to measurable deltas. Use reporting to compare estimated quantities and labor targets to actuals by crew, task type, and item category, then tighten assemblies and pricing rules based on what the field consistently delivers. This pays off after a run of similar service upgrades: a supervisor reviews closeouts, spots where travel and access conditions drive labor drift, and updates the estimating templates so the next quote reflects how the work performs in the field.

Other valuable features for electrical takeoff software

Veteran teams squeeze extra value when takeoff connects with downstream controls that close the loop from estimate to cash.

- Invoicing and payments: Push approved scope into invoicing and collect faster with integrated payments tied to the completed work.

- Service agreements and time tracking: Tie recurring scopes to service agreements and validate labor assumptions with time tracking on recurring visits and small projects.

- Fleet coordination: Sync crew routes and vehicle constraints through fleet management so dispatch matches truck capacity to staged materials and tooling needs.

The picks section stacks platforms and shows which options deliver these features under live service conditions.

Connect takeoff to service execution with BuildOps

See how takeoff quantities flow into scheduling to billing without duplicate entry.

6 best takeoff software for electrical contractors

Electrical takeoff software pays off when quantities move past the estimate and stay usable across scheduling, dispatch, purchasing, and closeout. The list below breaks down the best electrical takeoff software options with an operations lens, plus where each one fits in a service-heavy workflow and where electrical estimating takeoff software can still leave gaps.

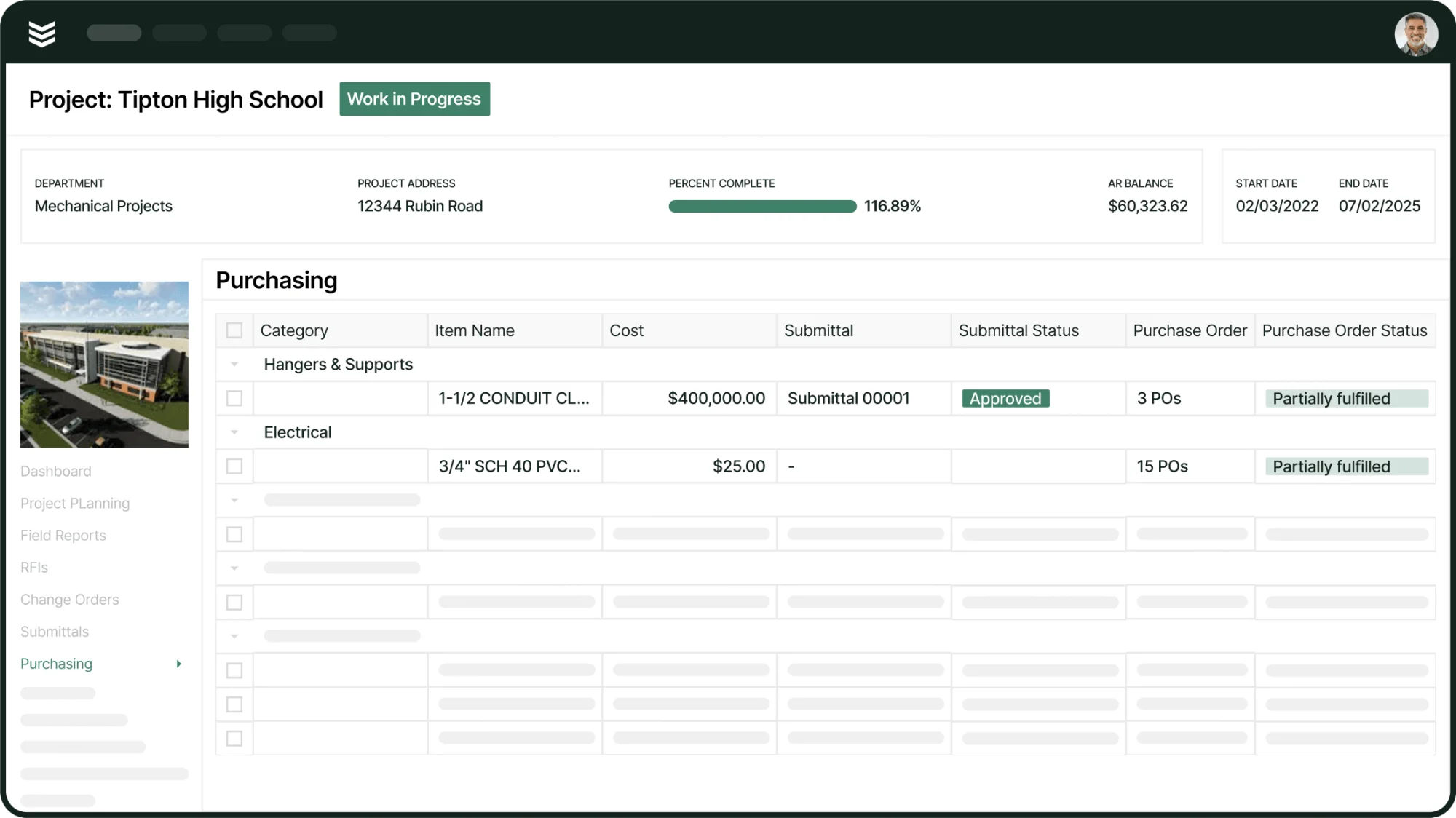

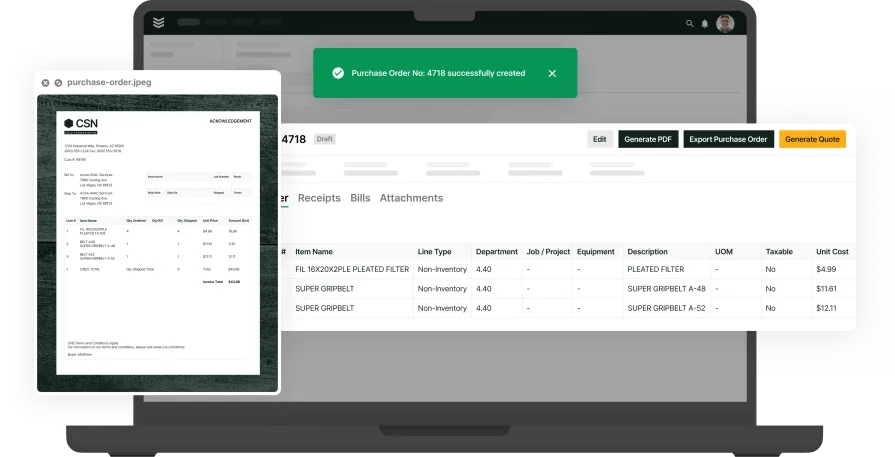

1. Best for commercial contractors: BuildOps

BuildOps connects electrical takeoff outputs to daily field service operations, so quantified assemblies flow into scheduling, dispatch, purchasing, and invoicing with a clean handoff. Estimators, service managers, and techs stay on the same scope, and mobile crews can work from counts, pick lists, and plan snippets tied to each visit. That end-to-end linkage fits commercial electrical teams that run recurring service plus project work and want tight estimate-to-actual visibility without duplicate entry.

How pricing works: BuildOps offers guided demos and works with contractors to design a pricing plan based on business size and needs

Features beyond takeoff: Native scheduling and dispatch, quoting, CRM, invoicing, payments, technician mobile app, reporting, service agreements, time tracking, and fleet coordination.

What sets it apart for commercial: Tuned to electrical service divisions juggling recurring maintenance, retrofit programs, and small projects, with cost visibility that helps PMs and service leaders react early.

See BuildOps in action

Walk through workflows and review field handoffs tied to approved quantities.

2. Best for residential: Buildxact

Image Source: Buildxact

Buildxact supports template-driven takeoffs, estimating, and client selections that tie back to quantities, which can work well for smaller residential electrical outfits quoting repeatable scopes and light project packages. Setup tends to be straightforward, and the workflow suits teams that keep estimating centralized and execution simple. For service operations that depend on tight dispatch coordination, deep assemblies, and field-first controls, the handoffs can land outside the system and slow the loop from takeoff to tech.

How pricing works: Tiered subscription with user and feature levels.

Features beyond takeoff: Estimating libraries, proposal generation, light scheduling, and client portals for approvals and variations.

What sets it apart for residential: Template-heavy workflows help renovation-focused teams quote consistently and keep homeowners aligned on scope and selections.

3. Best for general contractors: Procore

Image Source: Procore

Procore pairs takeoff with a broad project management suite that covers RFIs, submittals, financials, and field productivity, which fits GC-led environments with heavy documentation and many stakeholders. Electrical contractors supporting large commercial projects can benefit when quantities live alongside coordination workflows and compliance tracking. For service divisions prioritizing rapid quoting, dispatch speed, and mobile task execution, the platform footprint and learning curve can feel heavy for fast-turn work.

How pricing works: Annual subscription priced by product bundle and company profile.

Features beyond takeoff: Drawing and document control, correspondence and change management, subcontractor collaboration, and strong audit trails.

What sets it apart for general contractors: Enterprise controls and collaboration depth fit complex operations where documentation and trade coordination set the pace.

4. Best for small to mid-sized businesses: Stack

Image Source: Stack

Stack centers on browser-based takeoff with shared plan rooms, consistent markups, and template-driven counts that help electrical teams keep bid throughput high when service work and small installs overlap. Estimators can standardize device counts, lighting packages, and rough-in scopes, then export quantities into downstream estimating workflows with minimal friction. For a service-heavy operation that depends on native scheduling, dispatch, and mobile execution tied directly to takeoff quantities, it can leave key handoffs outside the same system, which adds coordination overhead.

How pricing works: Subscription plans by feature level and user access.

Features beyond takeoff: Plan collaboration, takeoff templates, bid management workflows, and export tools for estimating systems.

What sets it apart for small to mid-sized businesses: Cloud collaboration and template discipline help teams keep counts consistent across repeated electrical scopes without relying on local installs.

5. Best for subcontractors: Planswift

Image Source: Planswift

Planswift is known for fast 2D takeoff with customizable assemblies, digitizer support, and exports that many electrical estimators already have dialed in for device counts, conduit runs, and repetitive bid scopes. It can work well when your estimating crew wants speed on plan sets and a library approach that supports consistent electrical estimating takeoff software workflows across similar packages. For service-driven electrical teams that want quantities tied directly into dispatch, mobile execution, and estimate-to-actual visibility inside one operational system, it can require add-ons or separate tools to connect takeoff to day-to-day field service management.

How pricing works: License-based pricing with optional maintenance and add-ons.

Features beyond takeoff: Template libraries, trade plug-ins, and integration options for estimating and spreadsheet-driven workflows.

What sets it apart for subcontractors: Straightforward takeoff speed and assembly customization help lean estimating teams quantify scope quickly without a steep ramp-up.

6. Best for specialty trade contractors: Buildertrend

Image Source: Buildertrend

Buildertrend pairs takeoff with estimating, scheduling, and customer-facing communication that can help specialty contractors keep approvals, selections, and documentation organized alongside quantified scope. Electrical teams doing residential upgrades, light commercial work, or client-managed projects can benefit when proposals, change approvals, and daily logs sit in one workflow. For crews running high-volume service calls where dispatch speed, granular assemblies, and technician execution controls matter most, it may not cover the operational depth needed for field service at scale.

How pricing works: Tiered monthly plans by feature bundle and company size.

Features beyond takeoff: Client portal for approvals, scheduling, daily logs, change orders, and invoicing.

What sets it apart for specialty trade contractors: Strong customer communication and documentation support keeps scope decisions and changes tied to measured quantities across the job.

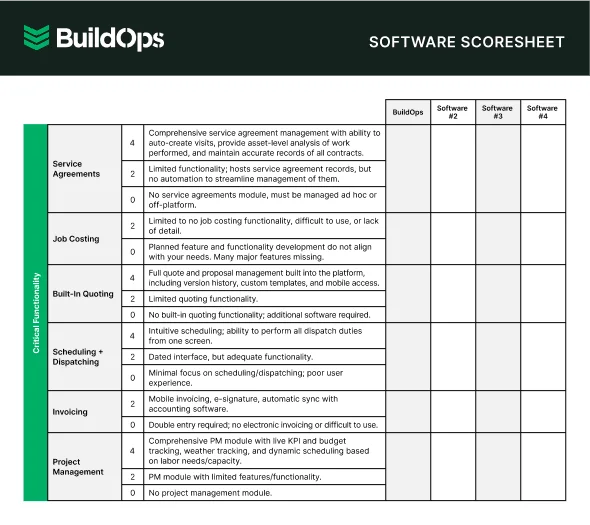

Get the software scoresheet

Compare the top tools at a glance with this easy-to-use scoresheet.

7 benefits of using electrical takeoff software

Veteran electrical teams move faster when estimates talk to the field. Electrical takeoff software turns plan sets into quantified scope that can drive labor hours, purchase lists, and work orders across installs, maintenance, and repair. In a service-heavy operation, the gains show up in cleaner handoffs, tighter revisions, and better alignment between what was sold and what gets executed.

1. Faster approvals and cleaner handoffs

Accurate counts flow into scope and pricing without re-entry, so approvals translate into actionable work orders with labor targets and material intent intact. That consistency reduces friction between estimator, dispatch, and foreman when field conditions force a scope update midstream. The broader workflow impact is easiest to see in field service operations, where estimate-to-execution handoffs define whether crews stay productive.

Deep Dive

For a deeper look at how service-driven electrical teams connect estimating, dispatch, and closeout, review this guide to electrical field service software.

2. Clearer pipeline forecasting

Takeoff-backed opportunities carry measurable scope, so opportunity values reflect assemblies and labor assumptions instead of rough ranges. That improves staffing and buy planning when the pipeline mixes quoted repairs, tenant improvements, and small installs. The framework in electrical bidding shows where measured scope tightens forecasting and reduces last-minute surprises.

3. Estimate-to-invoice consistency

A strong workflow keeps assemblies, change lines, and taxes consistent from takeoff to invoice, so customers see charges that match approved scope. That cuts rework in the office and shortens the payment cycle on service accounts. For billing controls that keep documentation and pricing aligned, see field service billing software.

4. Material planning that matches the job

Itemized takeoff supports staged materials and accurate kits, which prevents return trips caused by missing fittings, wrong device counts, or incomplete support hardware. This matters most on service work with tight access windows where crews get one clean shot. Clean material intent also reduces field improvisation that can distort labor actuals.

5. Fewer billing disputes

Line items tied back to measured scope reduce “prove it” cycles, because the invoice matches quantified work and approved deltas. That keeps approvals predictable when changes stack up across revisions. Clear scope traceability is one of the practical differences that separates the best electrical takeoff software from tools that stop at counting.

6. Real labor accountability

When time and production track against measured tasks, variance shows up early by crew and task type, not after closeout. That gives service leaders a clear path to adjust assemblies, production rates, or crew mix while work is still active. The levers that tighten this loop show up in electrical cost estimating.

7. Stronger service call triage and follow-up work

Measured scope improves job readiness before dispatch commits a crew, including planned duration, skill fit, and material staging. Techs arrive with clearer expectations and document follow-up work against quantified scope rather than informal notes. The routing and prep workflows behind that outcome are covered in electrical dispatch software.

4 important electrical takeoff software FAQs answered

Pros ask sharper questions, so these answers stay focused on takeoff software for electrical contractors who run service calls, retrofits, and small installs with crews in the field. Use them to pressure-test best electrical takeoff software choices based on handoffs, revisions, and closeout discipline. They also call out where electrical estimating takeoff software earns value through repeatable assemblies and estimate-to-actual feedback.

1. What is electrical takeoff software?

Electrical takeoff software converts plan sets into quantified devices, wire, conduit, and assemblies that drive labor targets, staged materials, and job costing across daily service tickets and small installs, keeping revisions and change-order deltas traceable from estimate to tech execution.

In practice, it acts as the scope backbone across estimating, dispatch, purchasing, and closeout.

2. How does electrical takeoff software work?

It starts with importing plan sets, setting scale, applying symbol auto-count where it holds up, and measuring runs and areas where detail matters. Assemblies map counts into labor units, materials, and task logic, so outputs can flow into work orders, buy lists, and internal cost buckets without re-keying.

Version control is the separator: addenda, sketch-driven changes, and field discoveries must produce clean deltas, so supervisors can see what shifted and why before labor and materials get committed.

3. Is electrical takeoff software worth the price for electrical professionals?

Yes—when it reduces revision rework, cuts return trips caused by missing materials, and keeps scope, labor targets, and billing aligned across service jobs. The value shows up in fewer pricing disputes, tighter labor control, and faster closeout when technicians capture real conditions that trigger approved changes.

The return improves when takeoff outputs connect directly to scheduling, dispatch, purchasing, and invoice-ready line items, so the office does not rebuild scope from scratch after the field day ends.

4. What are best practices for using electrical takeoff software?

These practices keep quantities, pricing, and field execution in sync. They assume a service-heavy operation where revisions, access constraints, and customer approvals shift scope midstream.

- Standardize electrical assemblies with approved labor units, material logic, and waste factors

- Lock naming conventions for devices, circuits, homeruns, and scope zones across the team

- Set a version-control rule for every addendum, including delta notes and approval dates

- Separate base scope, alternates, and options so pricing stays clean during revisions

- Map takeoff items to your internal cost buckets before bids go out

- Produce kitting lists from measured scope and verify staging before dispatch assigns crews

- Require field photos and notes for any quantity variance that impacts labor or materials

- Review estimate vs actual weekly by task type and crew mix, not only at closeout

- Update assemblies after trend repeats, then document the change so estimators stay aligned

- Archive final quantities, deltas, and outcomes per job type to tighten future bids

Great takeoff work only counts if it holds up once boots hit the site. In electrical service, that means quantities stay tied to how you run jobs: crew capacity, dispatch decisions, staged materials, change approvals, and closeout that matches what the customer signed. The best electrical takeoff software keeps scope stable through revisions and turns plan counts into field-ready tasks, pick lists, and labor targets your leads can trust.

The takeaway from this guide is simple: speed helps, but handoffs decide the outcome. When electrical estimating takeoff software connects to scheduling, dispatch, quoting, and billing, your team spends less time translating scope and more time executing it. That leads to cleaner pricing updates, fewer return trips from missing material, and tighter estimate-to-actual feedback that improves the next bid.

BuildOps fits when you want one platform that connects takeoff to commercial field service operations end to end, especially for teams running service plus projects with shared crews and cost controls. It also goes beyond plumbing takeoffs by supporting multi-trade field operations where estimating and execution have to stay aligned.

If you want to see how this would run with your service mix, we can walk through a real workflow from takeoff quantities to dispatch, tech execution, and closeout. If now is not the time, keep this guide as a checklist for evaluating any platform on your shortlist.

Takeoff to Field Control with BuildOps

See quantities flow from bid to crews without reentry.