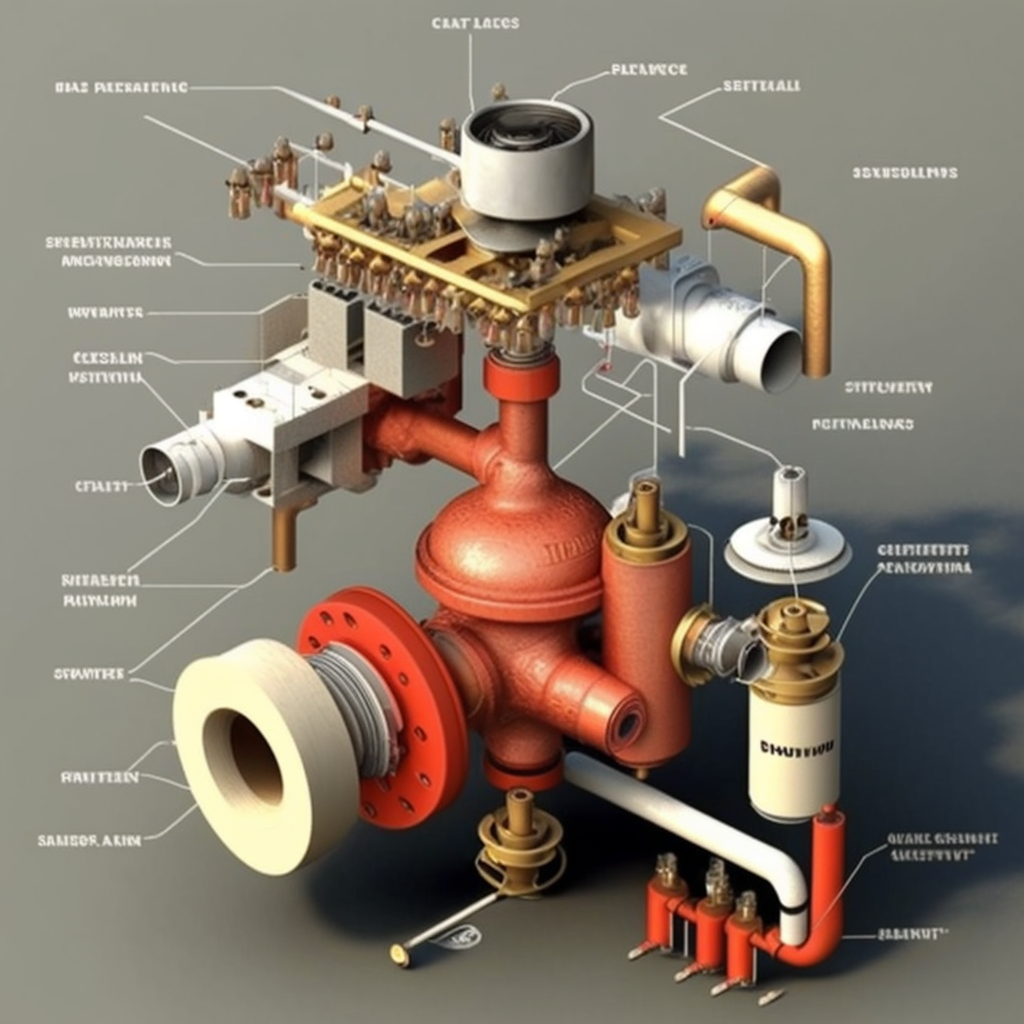

A fire sprinkler system is an integral part of a building’s fire protection system. It is composed of a number of components, which, when combined and installed correctly, can detect fires and activate suppression systems to reduce damage from them.

The main components of a fire sprinkler system are pipes, sprinkler heads, gauges, control valves, a water flow alarm, and an auxiliary drain. The pipes are typically made of galvanized steel or PVC, and are connected in a network to carry pressurized water to various parts of a building or structure. The sprinkler heads are installed at strategic positions along the pipes, and upon actuation, will release the water in a controlled manner and at a predetermined rate. The gauges are devices that allow the user to monitor the water pressure within the pipes, and also to detect any changes in pressure which may help detect a leak in the system. Control valves are used to regulate the flow of water from the supply to the sprinkler heads, and to manually shut off the water supply in an emergency or during maintenance.

The water flow alarm is connected to the pipes, and it will detect any changes in the water pressure, then alert personnel of a potential hazard. Lastly, the auxiliary drain is in place to prevent low points in the system where water could collect and freeze. This drain is connected to the main drain line.

In summary, a fire sprinkler system is an important part of any building’s fire protection system, and it is composed of several components such as pipes, sprinkler heads, gauges, control valves, water flow alarm, and an auxiliary drain. These components work in unison to detect fires and provide appropriate suppression.

What are the benefits of having a fire sprinkler system installed in office buildings?

Installing a fire sprinkler system in an office building provides numerous benefits. Firstly, due to the advanced technology used to detect fires, sprinklers can detect and suppress flames and smoke quickly and efficiently. This helps to reduce the amount of fire or smoke damage, preventing the spread of the fire and buying valuable time for those in the building to evacuate safely.

Additionally, having a fire sprinkler system installed means that a building will require fewer fire prevention methods, such as physical barriers or chemical fire suppressants. This will result in cost savings as fewer materials need to be purchased, so the installation is a one-off expense.

Having a fire sprinkler system also safeguards against the risk of fires, something which is important for a workplace where many people may be at risk, and ensures that business benefits from having a safe working environment. And, with a professional maintenance program in place, it can help an office building meet insurance regulations, thus reducing the business’s insurance premiums and protecting itself from any liability in the event of a fire.

In conclusion, having a fire sprinkler system installed in an office building provides numerous benefits. Not only does it provide increased protection for people and property, but it can also save time and money in both the short and long term, as well as ensuring compliance with insurance requirements.

What are the different types of fire sprinkler systems available?

There are several different types of fire sprinkler systems available to suit different needs and building types. The most common type is a wet pipe system, where pipes are filled with pressurized water, making them ready to deploy when necessary. This system is generally suited for buildings that are heated all year round, as the water in the pipes will not freeze.

Another type of system available is the dry pipe system, which is typically used in unheated buildings. These pipes are filled with air instead of water and are activated when a certain temperature has been reached, allowing the water to flow through the pipes.

A third type of sprinkler system is a pre-action system, which is a hybrid of the wet and dry pipe systems. In these systems, the pipes are filled with both air and water and are triggered by specific signals from external sources. This makes them ideal for applications such as preserving valuable documents or artwork, as only a small amount of water is used.

Finally, the most specialized type of sprinkler system is the deluge system, which is installed in areas where a quick response is needed. This system is made up of open-ended pipes with sprinklers attached to each end, and when triggered, the sprinklers open simultaneously to send large amounts of water quickly to the area in need.

In summary, there are a variety of fire sprinkler systems available that can suit different environments and needs. The most common are wet pipe systems, dry pipe systems, pre-action systems, and deluge systems. Each type offers distinct benefits that must be carefully considered before choosing the best system to install.

How does a fire sprinkler system work?

A fire sprinkler system works by detecting the presence of heat or smoke, which activates its individual components in order to suppress a fire. The main components of a fire sprinkler system are pipes, sprinkler heads, gauges, control valves, a water flow alarm, and an auxiliary drain. When smoke or heat is detected by the system, it will sound an alarm to alert those in the vicinity and activate the water supply. The pipes then transport pressurized water to the strategically-placed sprinkler heads installed throughout the building or structure. When activated, these sprinklers will release water onto the flame or area affected by smoke in a controlled manner at a predetermined rate. This helps reduce damage from fires as well as buys time for people to evacuate safely.

The gauges are used to measure the water pressure within the pipes, while the control valves help regulate the flow of water and shut it off in emergency situations. The water flow alarm is connected to the pipes and will detect any changes in pressure that may be indicative of a leak, alerting personnel of a potential hazard. Finally, an auxiliary drain is installed at strategic points along the pipe system which helps prevent low points from forming where water could freeze.

In summary, fire sprinkler systems work by detecting smoke or heat and activating its various components which transport pressurized water through strategically-placed sprinkler heads throughout a building or structure. This helps reduce damage from fires as well as buying time for people to evacuate safely. With the use of gauges, control valves, a water flow alarm, and an auxiliary drain, fire sprinkler systems ensure that buildings are adequately protected from fires.

What are the key components of a fire sprinkler system?

The key components of a fire sprinkler system are pipes, sprinkler heads, gauges, control valves, a water flow alarm, and an auxiliary drain. The pipes transport pressurized water to the strategically-placed sprinkler heads which are triggered by smoke or heat. The gauges measure the water pressure within the pipes while the control valves regulate its flow and shut it off in emergency situations. The water flow alarm is connected to the pipes and detects any changes in pressure that may be indicative of a leak. Finally, the auxiliary drain helps prevent low points from forming where water could freeze.

In conclusion, these components work together to detect fires quickly and efficiently by transporting pressurized water to the affected area at a predetermined rate.

What is the best placement for fire sprinkler heads?

The best placement for fire sprinkler heads is typically near the ceiling, at least eight inches away from any walls or obstacles. This allows them to be in the vicinity of an impending fire and helps ensure they will be able to effectively douse it with water. Additionally, if there are combustible materials like wood, cloth, or paper nearby, it is important to factor this into account when planning out sprinkler head placements as these materials can burn quickly and spread a fire.

In summary, the best placement for sprinkler heads is near the ceiling at least 8 inches away from walls and other objects. Proper consideration should also be given to any combustible material that may be close by in order to ensure that the sprinklers will be able to effectively combat the fire.

How are fire sprinkler systems maintained?

Fire sprinkler systems require regular maintenance in order to remain effective and reliable. This includes checking pipes for corrosion or leaks, ensuring the water pressure is at the correct level, inspecting sprinkler heads for damage or obstructions, cleaning out any sediment or debris that may have accumulated in the pipes, and testing the system regularly to ensure it is functioning properly. In addition to these steps, all parts of a fire sprinkler system should be checked by a qualified professional on an annual basis to make sure they meet safety standards and are working properly.

In summary, fire sprinkler systems need regular maintenance in order to remain effective and reliable. This includes checking pipes for corrosion or leaks, ensuring water pressure is set correctly, inspecting sprinkler heads, cleaning out sediment or debris that may accumulate in the pipes, and testing the system regularly. A qualified professional should also be consulted on an annual basis to make sure all parts of a fire sprinkler system meet safety standards and are working properly.

How effective are fire sprinkler systems in protecting against fires?

Fire sprinkler systems are highly effective in protecting against fires. Studies have shown that these systems can reduce the risk of fatalities by up to 81%, property damage by up to 70%, and the average fire size by up to 90%. Additionally, they can help contain a fire until firefighters arrive on the scene, allowing them more time to put out the blaze and save lives.

In conclusion, fire sprinkler systems are highly effective in protecting against fires. They can significantly reduce fatalities, property damage, and the average size of fires while also helping firefighters contain them until they arrive on the scene. As such, investing in quality fire sprinkler systems is important for any building or structure that needs additional protection from potential hazards like fires.

Are there limitations to fire sprinkler systems?

Yes, there are certain limitations to fire sprinkler systems. For example, the system will not be able to contain a fire if it is too large or spreads too quickly. Additionally, water pressure can be affected by changes in elevation and temperature which could prevent the sprinklers from working properly in some circumstances. Finally, the system may not trigger if there is not enough smoke or heat detected for it to activate its components.

In summary, there are certain limitations to fire sprinkler systems that should be kept in mind when considering their use. While they can provide effective protection against fires, their effectiveness may be reduced if the blaze is too large or spreads too quickly, water pressure drops due to changes in elevation or temperature, or not enough smoke or heat is detected. As such, they should be used in combination with other safety measures for maximum protection.