Keeping jobs on track doesn’t happen by accident. It takes structure. For contractors and techs managing field service work, work order management is that structure. It’s how you make sure every task gets scheduled, completed, and closed—without dropped details or wasted time.

Whether you're fixing HVAC systems, rewiring panels, or replacing pumps, your crews need a way to handle the chaos that hits once boots hit the ground. That’s where work order management comes in. It brings order to field service operations—turning scribbled notes and texts into a reliable, repeatable system. And as field service management becomes more connected and fast-paced, understanding how work order management fits into the bigger picture is key.

In this guide, we break down how it all works. Whether you're building your first system or looking to clean up an old one, here’s what you’ll find inside:

- Fundamentals & essentials of successful work order management

- Mastering the 7 key steps in the work order management process

- Using work order management systems

- Top 3 work order management system for contractors

- 10 work order management best practices to up your operations game

A clear, well-run work order management process doesn’t just organize your jobs—it keeps them moving. Up next, we’re digging into the fundamentals behind effective work order management, from the basics to what every contractor needs to know before putting it to work.

Fundamentals & essentials of successful work order management

Work order management gives structure to field service operations. For experienced contractors, it's the system that keeps teams aligned, jobs on track, and labor accountable. It connects what’s happening on-site with what needs to happen next.

Every step—request, assignment, execution, closeout—relies on a process that’s tight and repeatable. Strong fundamentals help prevent delays, miscommunication, and cost overruns. Without them, even simple jobs start slipping through the cracks.

What is work order management?

Work order management is the process of creating, assigning, tracking, and closing out field service tasks. It makes sure every job starts with clear instructions, reaches the right tech fast, and gets completed without job delays. A strong system improves crew efficiency and keeps operations tight.

What does a successful work order manager do?

A successful work order manager controls the flow of work from start to finish. They turn incoming requests into clear tasks, assign them to the right techs, and monitor progress without losing sight of deadlines or costs. The role requires precision, quick decisions, and complete awareness of what’s happening in the field. Key responsibilities include:

- Converting requests into detailed, actionable work orders

- Assigning tasks based on skill, location, and availability

- Monitoring job progress and updating statuses as work gets done

- Managing revisions, approvals, and completion steps

- Maintaining job records for billing, reporting, and compliance

- Communicating directly with techs, dispatch, and customers to remove blockers

Work order managers keep everything moving—no gaps, no missed steps, and no confusion about what happens next.

Benefits of automating your work order management operations

Manual systems slow crews down. Jobs get missed, notes go unread, and the office spends too much time tracking down updates. Automation fixes that. It keeps the whole operation tight—scheduling, job info, task updates—all handled fast and without guesswork.

- Quicker job assignments – Jobs hit the schedule without back-and-forth or hold-ups

- Fewer input errors – Auto-filled fields cut down on mistakes in job details

- Live status tracking – Everyone knows what’s done, what’s next, and what’s falling behind

- Solid job closeouts – Checklists and sign-offs make sure no task gets skipped

- Clear labor logs – Time and task data get saved without relying on memory

- Straightforward reporting – Numbers are tracked as the work happens—no extra admin

- Mobile access for techs – Crews see job info on-site without calling dispatch

- Less downtime – Jobs don’t sit in queue waiting on paperwork or missed handoffs

With automation in place, you spend less time chasing details and more time getting work done. Next, we’ll look at the types of work orders every contractor deals with—and how to handle each one.

6 different types of work order management

Field service work order management depends on understanding the job type before anything gets scheduled. Each type follows its own flow—what gets prioritized, how crews prepare, and what information needs to be passed down. In any field service environment, knowing these differences keeps work moving without confusion or delay.

- Preventive maintenance – Scheduled work meant to catch issues before they cause downtime. Common for HVAC tune-ups, filter changes, safety checks, and panel inspections. Crews follow a repeatable checklist.

- Corrective maintenance – Repairs triggered by wear, reports, or past inspections. These aren’t urgent but can turn costly if ignored. Examples include belt replacements, cracked seals, or off-spec readings.

- Emergency maintenance – Unplanned work that requires immediate response. This covers critical failures like system breakdowns, major leaks, or electrical hazards that put safety or uptime at risk.

- Inspection – Jobs focused on evaluating system conditions, logging results, and catching potential failures early. Inspections support compliance and flag problems before they turn into full repairs.

- General maintenance – Covers routine service work—tightening, cleaning, replacing basic parts—that keeps equipment functional and job sites in check.

- Installation – Applies when new equipment or systems need to be added, wired, or connected. Requires materials, detailed scope, and experienced techs to close it out right.

Each of these work orders moves differently through the system. Next, we’ll break down the steps that keep them organized from request to closeout.

Mastering the 7 key steps in the work order management process

Every job follows a flow. Whether it's a quick repair or a multi-day install, the work order management process keeps it organized from request to closeout. Missing even one part of the sequence creates delays, miscommunication, or wasted labor. For most contractors, using work order software for contractors makes this process easier to follow, faster to track, and harder to mess up.

1. Work request is created

It starts with a request—either from a customer, a technician, or a recurring schedule. That request needs to capture key job details: location, contact info, asset data, and a clear problem statement. If the initial info is incomplete, it throws off every step that follows.

2. Job gets reviewed and approved

Someone needs to review the request to verify if the job makes sense to move forward. This includes checking warranties, contracts, scope limits, and service history. It’s also where urgent jobs get flagged for faster scheduling. A fast but accurate approval step cuts down on confusion later.

3. Work order is created

Once approved, the request becomes a formal work order. This includes assigning a priority level, choosing the right task codes, adding materials or parts needed, and setting deadlines. The work order becomes the single source of truth for the job.

4. Assignment to a tech

Dispatch assigns the job to a tech based on availability, skill set, and location. Getting this wrong leads to rework or idle time. A good system shows who’s closest, who’s certified for the task, and what other jobs are in play. Field-ready access matters here—no one should be guessing.

5. Job is performed

The tech executes the work, documents everything as it happens, and updates status in the system. This includes time tracking, photos, notes, parts used, and customer sign-off. Any changes to the original scope should be flagged immediately and approved before continuing.

6. Closeout and verification

Once the job is done, it gets reviewed for accuracy. All fields should be complete, signatures collected, and job notes finalized. Closeout is also when the billing team, service manager, or client gets notified. If anything’s missing here, payment or warranty coverage could be delayed.

7. Record is archived and reported

The final step is storing the completed work order for reporting, audits, and future service reference. Job history helps teams prepare for repeat work, catch patterns in failures, and keep clients informed. This also feeds performance data that can shape staffing, quoting, and preventive plans.

Using work order management systems

Work order management systems give field teams structure and clarity. Instead of tracking jobs through calls, texts, or paperwork, everything runs through a single system—requests, assignments, updates, and closeouts. It keeps jobs moving, techs accountable, and information easy to find when you need it.

7 benefits of using a work order management software

For contractors managing field service work, software takes the guesswork out of scheduling, tracking, and documenting. Whether it’s a paid platform or free work order software, having the right tool in place helps crews focus on the job instead of the paperwork.

- Better visibility – Techs and managers can see job status, task progress, and crew availability without digging through emails or making phone calls.

- Accurate scheduling – Assignments are based on real-time availability, job type, and crew location—no whiteboards, no overlaps.

- Fewer delays – With mobile access to job details, crews show up ready. No second trips for missing info or miscommunications.

- Cleaner documentation – Notes, time logs, photos, and customer sign-offs all stay tied to the job, reducing billing errors and callback disputes.

- Improved closeouts – Digital checklists and required fields make sure the job gets wrapped right the first time.

- Faster reporting – Service history, time spent, materials used—all pulled automatically without chasing paperwork.

- Stronger communication – Updates move instantly between the office and the field, so no one's left out of the loop mid-job.

The system only works when the tools behind it actually support how your team operates. With dozens of platforms out there, choosing one that fits your crew, job types, and pace of work makes all the difference. Let’s break down a few top work order management systems built with contractors in mind.

Top 6 features to look for in a work order management solution

Work order management only works when the tools behind it support how crews operate in the field. The system needs to handle scheduling, tracking, updates, and job completion without slowing things down. These six features directly impact how smooth that process runs day to day.

- Scheduling – Crews need to see where they’re headed and what’s on deck without constant check-ins. A strong scheduling feature lays everything out clearly—assignments, timing, overlaps—so no one’s guessing what’s next.

- Dispatch software – The ability to send work orders straight to techs in real time is key. With field service dispatch software, updates hit the field fast, especially when jobs shift or emergencies pop up.

- Technician mobile app – Techs shouldn’t have to chase info mid-job. A solid technician mobile app gives them access to everything they need—job scope, service history, notes, and checklists—right from their phone.

- Invoicing – Getting paid depends on how clean the job data is when it hits billing. Invoicing tools that pull from completed work orders reduce errors and cut down the time from closeout to payment.

- Reporting – Tracking job performance and field productivity takes more than spreadsheets. Reporting features help you review time, costs, and history without digging through files, giving managers what they need to make decisions.

- Time tracking – Labor costs don’t leave room for guesswork. A time tracking tool that logs hours as work gets done keeps payroll accurate and gives visibility into how long jobs really take.

With these features in place, a work order system becomes a tool your team can actually rely on—not just another layer of admin. Now let’s look at a few systems that stand out for contractors and why they work in the field.

Top 3 work order management system for contractors

Finding the right system depends on the kind of work your crews handle and how your back office operates. Commercial contractors need something that handles complexity. Residential teams need speed. General contractors need flexibility. Here’s a breakdown of three solid options—each built for different types of work.

1. Best for commercial: BuildOps

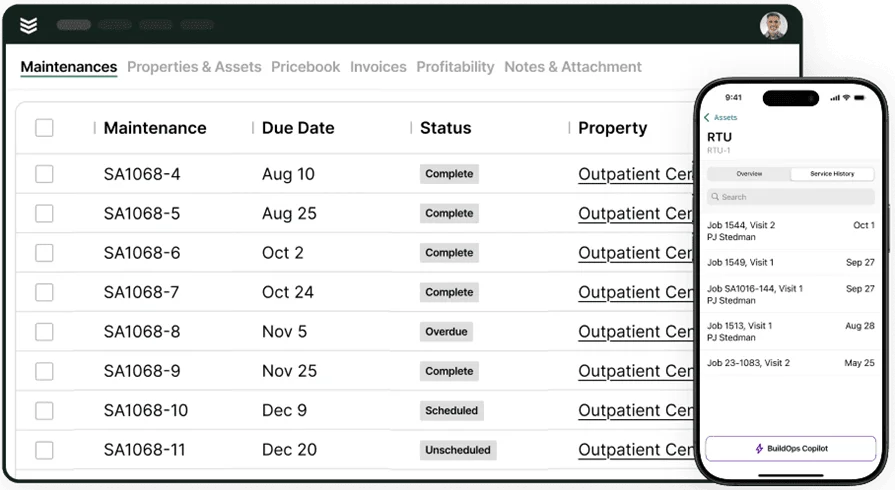

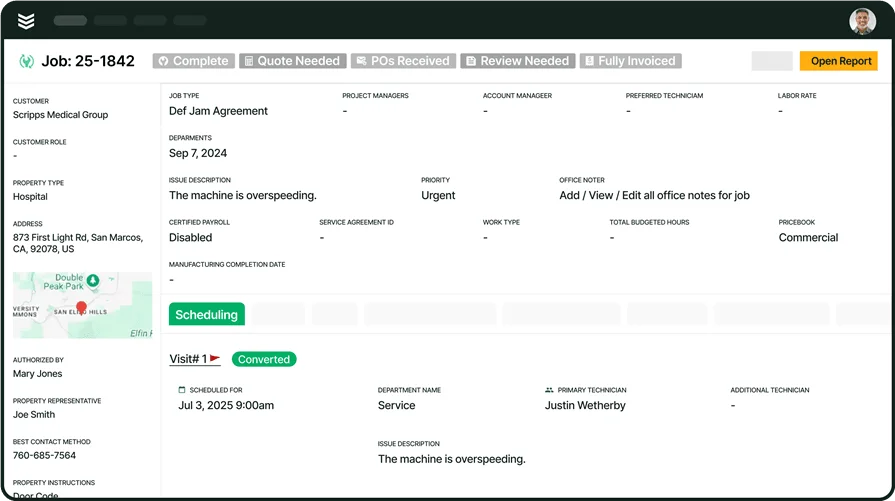

BuildOps was designed specifically for commercial contractors. It handles complex jobs, multiple crews, layered schedules, and detailed service histories without getting in the way. The platform was built to support growing field teams with real-time visibility across jobs, assets, and performance.

How pricing works: BuildOps offers custom pricing based on the size of your business and the modules you need.

What sets it apart for commercial: It connects the field to the office with scheduling, dispatch, asset tracking, and reporting all in one place. Built-in job costing and crew tracking tools make it easy to stay on budget and on time.

Key features beyond work orders: Project management, invoicing, service agreements, technician mobile app access, and more.

Give BuildOps a Try

Improve work order management for commercial teams working in the field.

2. Best for residential: Fiix

Image Source: Fiix

Fiix software focuses on basic work order functionality and maintenance tracking. It’s easy to use and quick to deploy, making it a good match for smaller residential teams. But it may fall short for contractors who need more control over complex field operations or larger job coordination.

How pricing works: Tiered pricing starts with a free version and goes up depending on features and users.

What sets it apart for residential: It includes asset tracking and a clean interface that helps smaller teams keep up with recurring maintenance.

Key features beyond work orders: Basic reporting tools, parts inventory, and calendar views.

3. Best for general contractors: PTC

Image Source: PTC

PTC supports a wide range of field service needs with flexibility in how work orders are created, tracked, and closed out. It’s built to be adaptable, but that can make it harder to use out of the box. Many contractors may find the system requires extra setup to match their workflows.

How pricing works: Pricing varies based on business size and selected modules. No public base price listed.

What sets it apart for general contractors: It offers job costing, asset control, and scheduling flexibility across trades and job types.

Key features beyond work orders: Fleet management, equipment monitoring, and contractor network integration.

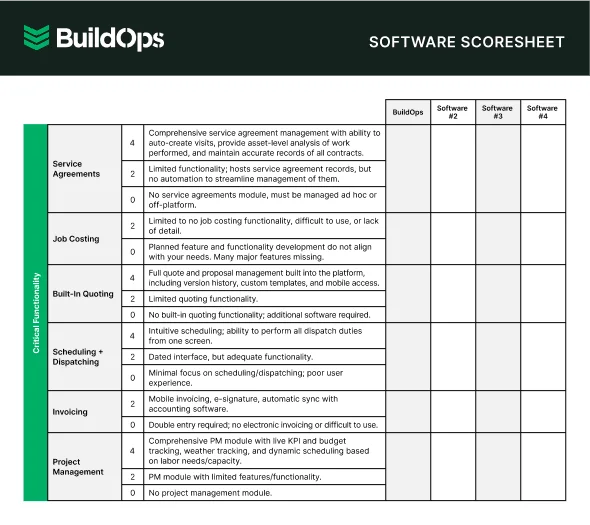

Download the software scoresheet

Compare leading software options with our easy-to-use scoresheet.

10 work order management best practices to up your operations game

Work order management keeps field service operations moving—but only when every step stays consistent. From the way jobs are created to how they’re closed and reviewed, these best practices help reduce delays, cut down on errors, and keep teams aligned in the field and the office.

1. Standardize how work orders are created

A solid job starts with a clear work order. Every work order should follow a template that includes job location, contact info, detailed scope, asset data, and clear instructions. Without a standard format, techs waste time tracking down info or show up unprepared. This also helps newer dispatchers or office staff avoid mistakes during intake.

2. Use scheduling tools to avoid missed windows

Time slots matter—especially when you’re stacking multiple jobs or managing SLA expectations. A reliable field service scheduling app gives your office visibility into every crew’s calendar and makes it easier to adjust on the fly. This cuts down on last-minute reschedules and keeps crews moving instead of waiting around or backtracking across town.

3. Prioritize clear dispatching

Dispatching isn’t just about speed—it’s about precision. Assigning work based on skillset, location, equipment needed, and urgency ensures the right tech lands on the right job. With a strong work order dispatch system, jobs hit the field faster with fewer mistakes or reassignments. This keeps both techs and customers from wasting time and builds trust with repeat clients.

4. Track work in real time

Work that isn’t tracked live creates blind spots. Real-time updates let your team see what’s started, what’s in progress, and what’s delayed—without waiting on status calls. It also helps managers step in when jobs stall or creep beyond their expected timeline. Tracking time, parts used, or issues as they happen leads to more accurate reporting and billing.

5. Close out jobs with full documentation

Closeouts need more than a checkbox. Every job should end with complete notes, signed approvals, before/after photos, and time logs. This information protects the business in case of disputes, supports warranty coverage, and speeds up billing. Techs should know that documentation is part of finishing the job—not something extra tacked on.

6. Keep invoicing connected to the job

When invoicing happens in a separate system or days later, mistakes creep in. Work orders and billing details need to stay tightly linked so time, labor, and parts roll into the invoice cleanly. Managing invoice and work order flow from one place keeps data tight and shortens the time to get paid. It also eliminates missed charges and underbilled jobs.

7. Integrate your accounting platform

Disconnected systems create double work and bad data. A work order platform that integrates with tools like QuickBooks work order management helps the accounting team match hours, track job costs, and generate reports without jumping between systems. It also reduces errors in payroll, invoicing, and job costing.

8. Review service order history regularly

Job history is more than a paper trail—it’s how you improve. Reviewing completed work orders helps catch repeat equipment failures, identify service trends, and pinpoint gaps in training. With the help of service order software, this review becomes quick, automated, and actionable. The more you know about your past jobs, the better you plan future ones.

9. Give techs mobile access to work orders

Crews shouldn’t have to call in for scope changes, missing info, or past job notes. A strong mobile system gives them access to everything they need—job details, customer info, asset history, and checklists—right on-site. This keeps the job moving and avoids confusion when plans shift mid-day. It also lets them update progress as it happens, not after the fact.

10. Audit completed jobs weekly

Waiting until month-end to review closed jobs leaves too much room for error. Weekly audits give you a tighter feedback loop to fix issues early—missing documentation, billing gaps, or warranty questions. It also helps verify that closeouts are actually complete, and gives service managers a chance to coach the team where needed. Regular review is how good work order systems stay sharp.

Dialing in your work order management process doesn’t just tighten up job flow—it stabilizes the whole operation. When crews know what’s coming, office staff has full visibility, and jobs move cleanly from request to closeout, the impact is immediate. Less time wasted, fewer mistakes, and stronger control over labor, costs, and customer expectations.

The reality is, most platforms offer bits and pieces of what you need—scheduling, dispatch, maybe mobile access—but rarely all in one place. That’s where an integrated field service management software makes the difference. BuildOps brings everything under one roof—from the first work request to invoicing and reporting—built specifically for commercial contractors who can’t afford disjointed tools slowing them down.

See BuildOps in action.

We help teams streamline work order management and boost revenue.