When your crew's juggling install deadlines, service requests, and emergency repairs, every minute counts. Miss one detail and it spirals—delayed jobs, frustrated techs, and wasted time in the field. That’s why work order dispatch software isn’t a luxury—it’s essential. It helps crews move smarter, not harder.

This guide walks you through what it really takes to run work order dispatch the right way—connecting scheduling, technician routing, and job management into one tight system. For teams buried in paper tickets or struggling to keep up with growing demand, it’s the blueprint to regain control. It’s also where work order dispatching meets field service management head-on, making everything from intake to closeout smoother.

You’ll learn how scheduling dispatching and work order management fit together, why smart tools beat spreadsheets every time, and how commercial contractors are using software to handle the load with fewer headaches. Here’s what we’ll cover:

- The essentials of work order dispatching

- How the work order dispatch process works

- 7 benefits of using work order dispatch software

- 10 best practices to tighten your work order dispatching workflow

- 3 top software solutions for dispatching work orders

- Industry-specific work order dispatching tips for commercial trades

Before we dive into process tweaks or software picks, let’s lay the groundwork. Knowing what work order dispatching involves—and what sets it apart from just scheduling—is key to making smart upgrades. Whether you’re a small service team or a large commercial crew, these fundamentals shape everything that follows.

The essentials of work order dispatching

Work order dispatching is a core part of any field service operation. It determines which tech gets which job, when they’re expected to arrive, and what information they carry with them. Having a good system for work order management improves response times, reduces missed details, and keeps teams aligned. This section outlines what dispatching involves and how it fits into the broader picture of job management.

What does work order dispatch actually include?

At the heart of it, dispatching is the act of assigning jobs based on availability, qualifications, and field conditions. It involves more than just plugging names into a schedule. Dispatchers need to track which techs are nearby, who’s licensed for specific tasks, and whether the right parts are on hand before releasing a job.

This is where work order dispatch software becomes necessary. It centralizes scheduling, crew locations, equipment tracking, and job history so that dispatchers can make fast, informed decisions without needing to chase information across multiple tools.

As job volume increases, the ability to adjust assignments in real time becomes essential. With multiple crews in the field, the margin for error shrinks. A solid dispatch system reduces communication gaps and gives everyone—dispatchers and field techs alike—a clear picture of what needs to happen.

Where dispatching ends—and scheduling begins

Work order scheduling and dispatching often run side by side, but they handle different responsibilities. Scheduling focuses on future planning: setting technician shifts, blocking out job windows, and preparing for upcoming work. Dispatching happens in the moment. It’s where those plans get adjusted based on job updates, delays, cancellations, or new requests.

Some teams build their processes around clearly defined scheduling structures. If you're looking at how to approach that aspect, field service scheduling outlines common frameworks used to organize technician availability and job timing. On the dispatching side, managing real-time changes and daily field coordination is part of what makes scheduling and dispatching such a critical operational pairing.

Why work order dispatching is very important

Every service operation depends on how quickly and accurately jobs move from intake to completion. Without a clear system for dispatching work orders, it’s easy to fall behind—even when the schedule looks solid on paper. Delays start stacking up, jobs get reassigned without context, and technicians show up without the full picture.

Work order dispatching brings structure to that process. It keeps techs moving efficiently between jobs, ensures jobs are matched to people with the right qualifications, and cuts down on the back-and-forth that slows teams down. The benefits extend across the board:

- Better use of technician time and travel

- Fewer missed appointments or incorrect job assignments

- Stronger communication between office and field

- Faster response to changes during the workday

In commercial service work—where multiple crews, service tiers, and job types often overlap—those details make a difference. Dispatching becomes the link between customer expectations and field execution. It gives dispatchers the ability to prioritize jobs based on urgency, match techs based on skill and location, and keep everyone updated as the work progresses.

For teams managing scheduling dispatching and work order management as part of their daily workflow, having a structured dispatch system improves how everything runs. It means fewer errors, clearer accountability, and jobs that get closed out with the information needed for billing and reporting—all without chasing down updates. Next, we’ll break down the work order dispatch process step by step, showing how each stage—from intake to final update—fits into a system that works.

How the work order dispatch process works

Work order dispatching isn’t a one-and-done task. It’s a step-by-step process that starts the moment a service request comes in and continues until the job is closed out, documented, and ready for billing. Each stage has a direct impact on how smooth or messy the day gets.

The process below builds on the typical field service management process workflow, but here it’s focused specifically on how dispatching functions within work order management—where job details, technician availability, and customer timelines all need to sync up in real time.

1. Job intake and assessment

It starts with the request. Whether submitted through a portal, phone call, or automated system, the dispatcher’s first responsibility is to assess the work order. That includes verifying location, type of issue, service history, level of urgency, and any special conditions. This stage determines how the job fits into the day’s load—and if it needs immediate action or can be scheduled for a later time. A solid intake step prevents downstream issues like incomplete work orders or missed details.

2. Technician assignment based on skill and availability

After intake, dispatchers review available technicians. But this isn’t just about who’s free—it’s about who’s right for the job. Licensing, previous experience with the equipment, and current location all factor in. Work order dispatch software often assists here, filtering options by certifications, availability, and even past performance. This step ensures the work order gets assigned to someone who can complete it correctly on the first visit.

3. Schedule fit and job release

Once a technician is matched, the next step is to assign the job within the live schedule. Dispatchers look at how long the job will take, travel time, and any overlap with other scheduled work. If the schedule is tight, adjustments may be needed to prevent delays across other jobs. The full work order is then dispatched to the technician’s mobile device, with all relevant information—location, access notes, customer expectations, and materials required.

Send the best tech

Automatically optimize the best job to send each tech to.

4. In-progress job support and updates

With the technician in the field, dispatchers switch to real-time monitoring. Delays, material shortages, or new service requests can trigger schedule shifts. The dispatcher’s job here is to stay ahead—rerouting as needed or creating follow-ups if the job scope changes. Technicians update their status through the software—checking in, uploading notes, and flagging any issues that could impact the timeline. This keeps the office informed and helps maintain visibility over multiple open work orders.

5. Closeout and follow-through

Once the job is finished, the technician logs the outcome, uploads supporting materials, and closes the work order. The dispatcher then reviews everything to make sure it’s complete—notes, photos, labor hours, parts used. From there, the work order flows into the next system: billing, reporting, or future scheduling. If follow-up work is needed, a new job is created and slotted into the workflow. This final step ensures the job is fully documented and ready for the next phase without manual cleanup.

Next, we’ll cover 7 ways work order dispatch software improves operations—highlighting where real gains come from once the process is supported by the right tools.

7 benefits of using work order dispatch software

Work order dispatching is more than assigning jobs—it’s how service teams stay efficient, accountable, and in sync across the field and office. When managed through a centralized platform, the improvements show up in every part of the process: faster responses, fewer delays, and better job tracking. Here’s a closer look at how work order dispatch software strengthens operations—and where it fits into the broader systems contractors rely on.

1. Faster, more accurate job assignments

Instead of relying on memory, spreadsheets, or whiteboards, dispatchers can assign jobs in seconds using filters for availability, skill sets, certifications, and technician location. This is especially useful in high-volume service environments where jobs need to be released quickly and correctly.

Systems that follow field service automation software principles can also automate parts of the assignment process—helping prioritize urgent jobs or suggest techs based on recent performance. For busy teams handling dozens of open work orders a day, this reduces delays and keeps the schedule moving without constant oversight.

2. Fewer errors across scheduling and rescheduling

Double-bookings, missed appointments, or assigning a job to someone lacking the right license can derail the day. Work order dispatch software helps flag these issues before they happen by showing a live view of current schedules, technician workloads, and job dependencies.

Many platforms also connect dispatching directly to broader systems for contractor dispatch management, ensuring that all scheduling logic—drive time, recurring work, or resource conflicts—is factored in automatically. This helps reduce the manual burden on dispatchers while improving reliability across the board.

3. Real-time updates and mid-job coordination

Once a job is dispatched, things don’t always go according to plan. The technician might run into access issues, delays, or additional problems that expand the scope. Work order dispatch software allows for real-time communication between techs and the back office, ensuring changes are tracked and adjustments are made without slowing down the rest of the schedule.

When part of a full field service business process automation setup, these real-time updates don’t just help dispatchers—they feed into job documentation, customer communication, and future scheduling decisions as well.

4. Automated, timely customer communication

In service operations, customers often call in asking where the tech is or when the job will be done. When those updates aren’t automated, it adds friction and clogs up internal communication. Modern dispatch software can automatically send ETA updates, service alerts, or technician arrival confirmations based on field status.

When this functionality is tied into CRM dispatch software, it becomes even more powerful—allowing dispatchers to track job history, preferred appointment times, or contact notes without toggling between systems. This not only improves the experience for the customer—it keeps the entire operation running with less back-and-forth.

5. Complete job documentation in one place

From arrival time and job duration to photos and material usage, every touchpoint gets logged directly into the work order. This eliminates the need for technicians to fill out forms after the fact or rely on memory for job notes. Everything is tracked in real time and tied directly to the original work order.

That level of visibility is especially useful when reviewing performance, building reports, or resolving customer questions. It also ensures nothing is missed during closeout, so follow-up work and billing can proceed without confusion or extra calls.

6. Improved technician accountability and performance tracking

When work orders are tracked with GPS, time stamps, and detailed technician updates, it becomes easier to measure how long jobs take, how efficiently routes are run, and how often first-time completion is achieved. These metrics help teams improve—not by guessing—but by relying on actual performance data.

Systems that integrate this data with dispatching workflows also support better workforce planning. Managers can assign jobs based on historical strengths or route technicians more efficiently based on previous outcomes.

7. Cross-functional coordination without rework

Work order dispatching doesn’t live in a vacuum. It’s tied to scheduling, quoting, invoicing, reporting, and compliance. A good system eliminates the need to re-enter job data across departments by connecting dispatch with other operational tools.

When this coordination is part of a broader field service automation software platform, every team—from accounting to customer service—gets access to up-to-date job details without needing to chase down field notes or handoffs. The result: faster billing, cleaner reporting, and less administrative overhead.

10 best practices to tighten your work order dispatching workflow

Even experienced teams run into dispatching issues—missed jobs, misrouted techs, unclear job details. The fix usually isn’t hiring more people or adding new tools. It’s tightening up the process. This section breaks down 10 practical ways to improve how dispatching fits into your daily work order management. From intake through assignment and job closeout, these best practices build on the foundation laid in our comprehensive guide to field service dispatching, but focus on specific, actionable improvements for service teams handling complex schedules and multiple field crews.

1. Standardize your intake process

Every dispatching issue downstream starts with a missed detail at intake. A technician heading to the wrong address or showing up without key parts often traces back to incomplete or inconsistent job info. Use a structured intake checklist to ensure you’re always capturing the basics: job type, location, urgency, asset info, and special access notes. Using a field service ticketing system helps enforce consistency by collecting all the right inputs up front—reducing guesswork and follow-up later.

2. Assign based on skills, not just proximity

Sending the closest tech might save time on the map, but it can cost time on the job if they’re not qualified. Build your dispatching logic around certifications, experience, and familiarity with the job type. Platforms built with field technician dispatch software allow dispatchers to quickly filter techs by qualifications—so the person showing up knows what they’re walking into and has what they need to get it done right the first time.

3. Give dispatchers real-time field visibility

Dispatching doesn’t stop once the job is assigned. Field conditions change—jobs take longer, materials run short, or emergencies bump others down the line. Dispatchers need live access to technician status, job progress, and active service requests. That’s where field service dashboards come in. They pull all key info—job start times, check-ins, delays—into one place, helping the team make faster calls as the day evolves.

4. Build a clear escalation path

When a job runs off track, your team needs more than improvisation. Define exactly what happens when a tech needs backup, when a job can’t be completed, or when a customer issue requires escalation. Having a policy in place gives dispatchers confidence to act quickly—without needing to hunt down answers in the moment. This also reduces time lost waiting on manager approvals or callbacks.

5. Automate the routine scheduling steps

When dispatchers spend time chasing down tech availability or adjusting recurring work orders manually, they lose time for higher-value work. Automating recurring job placement, availability matching, and drive-time optimization lightens that load. Tools like the field service scheduler help make these adjustments easier by visually mapping out the day and preventing overlaps before they happen.

6. Use dispatching tools that integrate with scheduling

If dispatching and scheduling live in different systems—or worse, different teams—you’re going to see friction. Dispatchers need access to the full schedule to adjust jobs on the fly and avoid disrupting the rest of the day. That’s why teams that adopt connected scheduling and dispatch software often report fewer missed jobs, tighter timelines, and better communication between field and office.

7. Track field performance with real metrics

You can’t improve what you’re not measuring. Look at key field metrics like response time, job duration, first-time completion rate, and reschedules per week. These numbers give you insight into where your workflow is breaking down. To simplify tracking, build out reporting dashboards with your dispatch tool or connect them through a field service metrics and KPIs framework so leadership and operations are working from the same data set.

8. Require live check-ins and job status updates

Dispatchers need to know where each job stands—especially when planning the next few hours. Require techs to log status updates at critical moments: on-site arrival, job start, pause, and completion. This creates a real-time map of field activity that dispatchers can act on.

9. Revisit and refine dispatching rules quarterly

What worked six months ago might not work today. New techs, added services, and changing job types mean your dispatching rules should evolve too. Make it a habit to review how work orders are assigned, routed, and prioritized—then adjust based on data and team feedback. Refining your tagging logic, technician groups, or routing zones takes minutes but can have a noticeable impact on scheduling flow.

10. Connect dispatching to follow-up and next steps

Once the job is done, the process shouldn’t stop. Dispatchers play a key role in flagging additional work, creating follow-up visits, or identifying gaps in the original work order. Make sure there’s a direct line between dispatching and the teams handling quotes, billing, or customer feedback. That connection turns dispatch from a day-to-day function into a driver of future revenue and smoother operations.

3 best solutions for dispatching work orders

Finding the right dispatch solution depends on how your team works—not how the software markets itself. Some platforms handle simple job assignments well but fall short when you're managing high volumes, rotating techs, or repeat service contracts. Others try to do everything and end up missing what matters most: getting work orders out fast and keeping the crew aligned.

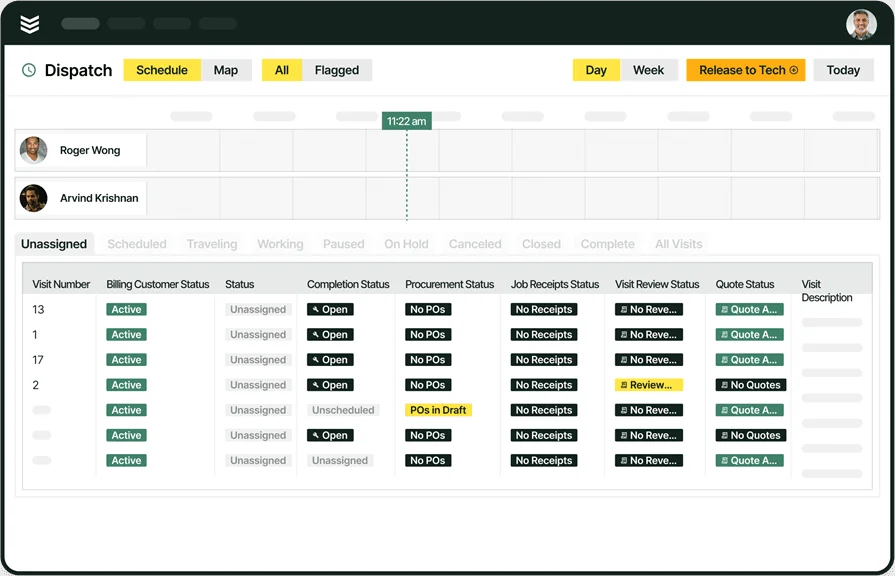

When dispatching is tied closely to your work order management system, your team gets more than a calendar—they get a real-time view of the field. The three platforms below offer strong dispatching tools, but the fit depends on whether you’re focused on commercial coordination, homeowner scheduling, or modular flexibility.

6 key features to look for in field dispatch software

The right feature set can turn dispatching from a reactive task into a controlled process. It’s not just about assigning jobs—it’s about giving dispatchers the tools to act quickly, support techs in the field, and close out work without missing a step. Whether you’re fine-tuning how jobs get scheduled or building a smarter field-to-office connection, these features make the difference. Here’s what to look for when evaluating dispatch software:

- Real-time scheduling - Work rarely sticks to a fixed plan, so your tools should move with it. With real-time scheduling software, dispatchers can shift assignments on the fly, view who’s free, and adjust timelines without blowing up the day. This matters most when you're juggling last-minute service requests or rescheduling work mid-route.

- CRM-connected job history - Dispatching decisions get easier when the system knows your customers. Tools with built-in CRM capabilities let dispatchers see past service notes, equipment details, and job preferences—so the next call isn’t starting from scratch.

- A mobile app that actually works in the field - When the app fails, your techs fall back on calls and guesswork. A solid field technician mobile app makes it easy to view work orders, check in, add photos, and close out jobs—all without circling back to the office or chasing paper forms.

- Accurate time tracking and job logs - Dispatchers need to know when a job starts, how long it takes, and when it’s done. Time tracking tools built into your dispatching system give you that view—without relying on end-of-day reports or memory. That’s key for payroll, billing, and project tracking.

- Service contract management - Recurring visits and long-term contracts only work if dispatch can track preferred time windows, renewal terms, and service history. Service agreement tools connect those details to the job file, so techs don’t miss key requirements and dispatchers can book with confidence.

- Fleet awareness built into the schedule - When a job needs a specific vehicle or toolset, dispatchers need to know what’s available—not just who. Fleet tools help teams assign jobs more efficiently, avoid overlaps, and keep vehicles on a logical route—especially when fuel costs and time matter.

Many platforms claim to handle work order dispatching, but few fully support the entire lifecycle from creation to completion. Below are three software solutions that stand out. Each one brings a different strength to the table depending on how your team operates, what types of jobs you run, and how much control you need from the dispatch board.

Top 3 work order dispatching software

Not every platform handles commercial demands the same way. A tool built for small home services can fall short when managing hundreds of work orders, multiple techs, and job coordination across teams. These three software solutions offer strong dispatching tools—but depending on your crew size, job volume, and service mix, some may fit better than others.

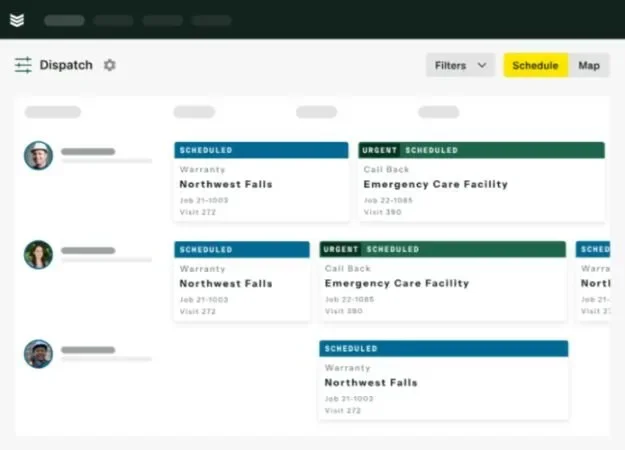

1. Best for commercial: BuildOps

BuildOps was built specifically for commercial contractors managing complex service operations. It brings dispatching, work order management, quoting, job tracking, reporting, and scheduling into one system—so teams don’t have to bounce between tools or lose time syncing data. Everything feeds into one workflow, from job intake to technician updates and billing.

How pricing works: BuildOps uses a custom quote model based on features, technician count, and company size.

Features beyond dispatching:

- Create estimates directly from the field

- Track project progress in real time with live dashboards

- Access customer histories and service records in one place

- Equip techs with mobile tools for job updates, documentation, and time tracking

What sets it apart for commercial: BuildOps supports multi-location jobs, longer project timelines, and real-time updates across field and office teams. It’s designed for precision, not patchwork—making it reliable when job volume and technician coordination are high.

Give BuildOps a Try

We’ll help you handle commercial workflows without gaps or bolt-ons.

2. Best for residential: ServiceTitan

Image Source: ServiceTitan

ServiceTitan focuses on residential contractors, offering a clean interface, mobile access, online booking, and smart automation for scheduling and communication. It helps HVAC, plumbing, and electrical businesses keep customers informed with real-time updates, reminders, and self-service tools. However, it’s not always the right fit for teams with complex service layers or commercial needs. Some smaller teams also find ServiceTitan’s pricing and feature gating hard to scale with—premium features may be locked behind higher tiers.

How pricing works: Quote-based, with features and access levels varying by team size and needs.

Features beyond dispatching:

- Built-in customer communication tools and feedback capture

- Recurring service plan automation

- QuickBooks integration for accounting

What sets it apart for residential: It’s customer-focused, making it easier for homeowners to book, reschedule, and stay informed. For smaller companies or those just starting out, however, the cost structure might outweigh the benefit.

Check out our side-by-side comparison of ServiceTitan and BuildOps to see which one has the work order dispatching features that better suit your crew.

3. Best for service teams needing modular flexibility: Zuper

Image Source: Zuper

Zuper offers a modular approach to work order management and dispatching. Designed for flexibility, it supports task assignment, route optimization, and technician tracking—all customizable to fit different field service needs. Teams can automate job allocation, set SLA rules, and update work orders in real time through Zuper’s mobile app. It’s especially useful for companies looking to stitch together different systems using open APIs, but may require more technical setup and third-party tools to reach full functionality.

How pricing works: Tiered pricing based on user count and features, with custom enterprise packages available.

Features beyond dispatching:

- Route optimization and live GPS tracking

- Real-time work order updates and status flags

- Integrations with CRM, ERP, and IoT platforms

- In-app communication between field crews and office teams

What sets it apart: Zuper gives teams the freedom to tailor their dispatching workflows, down to task-level customization. That said, companies without in-house tech support or integration resources might find the setup less intuitive out of the box.

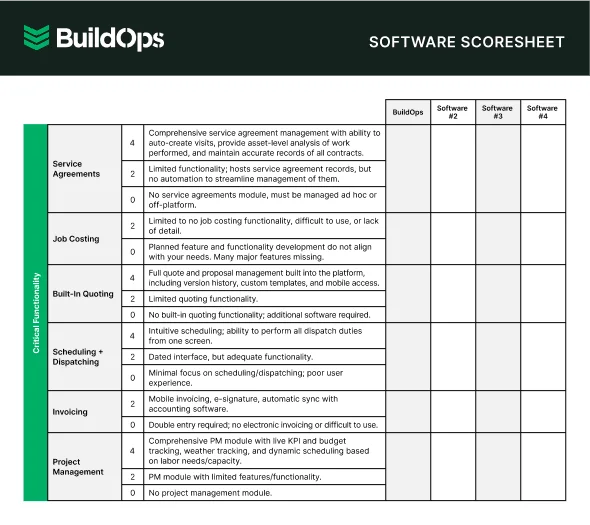

Compare tools at a glance

Our scoresheet helps you compare and select work order management software.

Industry-specific work order dispatching tips for commercial trades

Dispatching work orders looks different depending on the trade. What HVAC teams deal with day to day won’t be the same as what plumbing, refrigeration, or fire safety crews face. Some jobs need fast-turn emergency response. Others depend on permit timelines, recurring service contracts, or compliance windows.

That’s why dispatching work orders effectively means understanding how each trade handles technician coordination, job assignment, and field documentation. Below are specific tips for dispatching across commercial trades—each with different job flows and field conditions that shape how work order dispatch software should be configured.

HVAC work order dispatching

HVAC teams often manage seasonal spikes, recurring maintenance jobs, and emergency service—all in the same week. Dispatchers need to slot in last-minute repairs without missing preventive maintenance schedules or double-booking techs. The most effective HVAC shops organize dispatching around technician specialties and preferred customer time windows using HVAC scheduling and dispatching tools.

Get the commercial growth report

Discover what successful HVAC companies are doing to grow their business.

Refrigeration contractor dispatching

Cold storage failures and time-sensitive repairs require refrigeration teams to be ready to move quickly. Techs often need specialized certifications and access to temperature-controlled vehicles or tools. Dispatching in this space focuses on on-call availability, job criticality, and fast turnaround—something many contractors build into their refrigeration contractor software setup.

Electrical dispatching and job management

For electrical contractors, dispatching is tied closely to project phasing and compliance scheduling. Permits, inspections, and multi-stage job plans all factor into how work orders get dispatched. Using electrical dispatch software helps align job sequencing with technician licenses, ensuring the right people show up at the right stage of the work.

Plumbing work order coordination

Plumbing jobs mix planned installs, maintenance calls, and sudden emergencies. Dispatchers need to prioritize requests quickly while keeping techs equipped with access notes, tools, and the right parts. Contractors in this trade often rely on plumbing dispatch software to route calls and manage job types without adding manual work for the office.

Fire safety dispatching

In fire protection, missed service windows or sending the wrong tech can mean compliance failures and liability risks. Work order dispatching in this space has to account for certification tracking, system-specific knowledge, and deadline-driven inspections. Many firms use fire safety dispatch software to structure their workflows and stay audit-ready.

General contractor dispatch management

General contractors often juggle service calls and project-based dispatching. That means one platform has to support both planned and reactive work without losing visibility across teams. Contractor dispatch management systems help coordinate shifting job schedules, multiple crews, and ongoing work at different locations—especially when jobs change day to day.

Work order dispatching controls the pace of the job. It decides when techs move, what jobs get done, and how well the rest of the operation stays aligned—from scheduling and updates to invoicing and reporting. When dispatch and work order management are tightly connected, service calls close out faster, crews stay productive, and the office spends less time cleaning up loose ends.

Contractors who manage busy teams across multiple job types know that a disconnected system causes delays, double entry, and missed details. The right software links the field with the office and gives dispatchers the visibility they need to make decisions quickly. Platforms like BuildOps are designed with that in mind—combining scheduling, work order tracking, and dispatching into one system that fits how commercial field service actually runs.

See if we fit your setup

We handle dispatching, work orders, and crew management—all in one platform.